ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

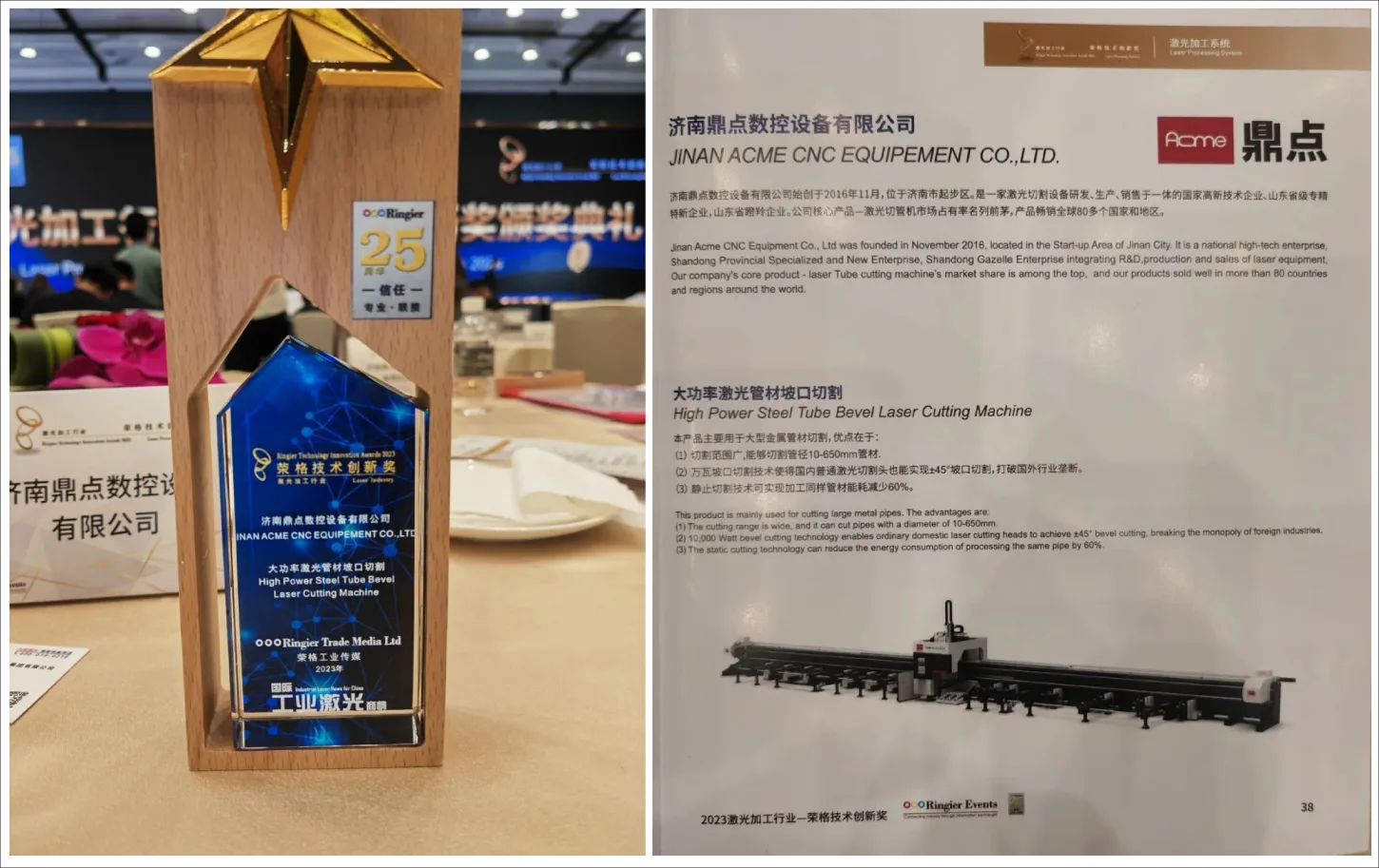

On April 26, 2023, the 2023 Laser Processing Industry-Ringier Technology Innovation Award Ceremony hosted by Ringier Industrial Media was grandly held in Shanghai. Many professionals from award-winning companies, jury representatives, industry mainstream media and professional buyers gathered together to summarize the innovative achievements and talk about the future. After 4 months, after professional review and strict selection, our company's "High-power Laser Tube Bevel Cutting" won the 2023 Laser Processing Industry-Ringier Technology Innovation Award!

As one of the Ringier Technology Innovation Award series of activities, the China Laser Processing Industry Innovation Award is currently one of the most influential and authoritative awards in China's laser industry. This award is a great encouragement and spur ACME, representing that ACME's independent innovation results have been recognized by more experts and users! ACME's passion and hard work in research and development will be remembered!

Strength creates extraordinary, focus creates quality products

With the deep implementation of national strategies and economic development, the manufacturing industry has an increasing demand for automated and intelligent production models. ACME Laser takes user needs as its service purpose and constantly overcomes technical barriers. The high-power laser pipe bevel cutting technology developed by our company breaks the monopoly of foreign industries, and ordinary laser cutting heads in China can also achieve ±45° bevel cutting. In addition, the independently developed static cutting is also a necessary technology for high-power pipe cutting. By adding the Y-axis, the pipe is stationary and the cutting head reciprocates. When processing the same pipe, energy consumption is reduced by 60%. It is more friendly to complex graphics. Combined with the self-developed heavy-duty full-stroke pneumatic chuck, 16-500mm pipes can be processed in batches, solving the pain point that laser cutting cannot be used in the heavy pipe industry.

In terms of energy saving and emission reduction, this method can achieve a photoelectric conversion efficiency of 40%. Compared with plasma and CO2 cutting methods, it can save more than 80% energy. At the same time, it can reduce 90% of dust and smoke. In addition, laser bevel cutting has a strong beam, small slits, good splicing effect, and no secondary processing is required, which saves labor costs and reduces costs and increases efficiency.

As domestic laser tube cutting technology continues to be mature, laser tube cutting has been used more and more widely in recent years. Many industries have slowly changed their traditional production methods and introduced laser tube cutting machines. In the future, ACME will continue to focus on the research and development and production of laser cutting machines, break through more technical barriers, master more core technologies, provide global customers with intelligent comprehensive solutions for laser cutting, and empower the transformation and upgrading of China's manufacturing industry!