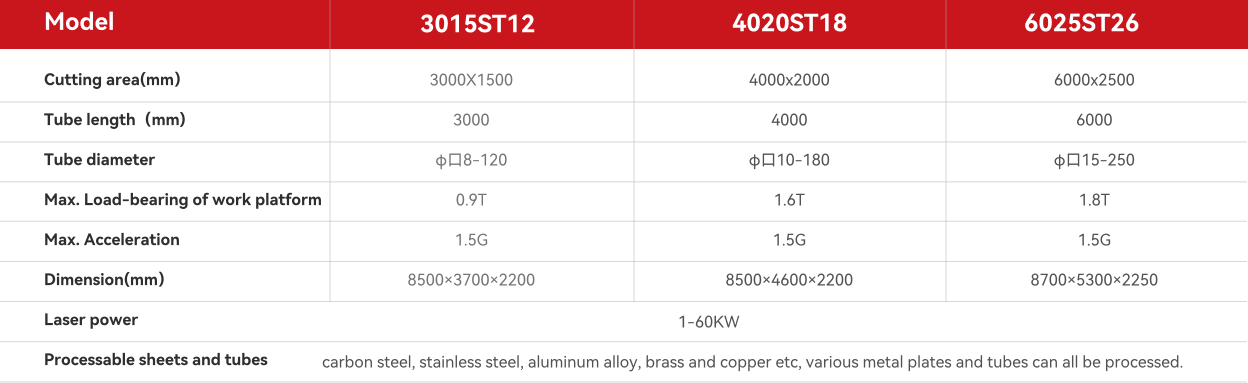

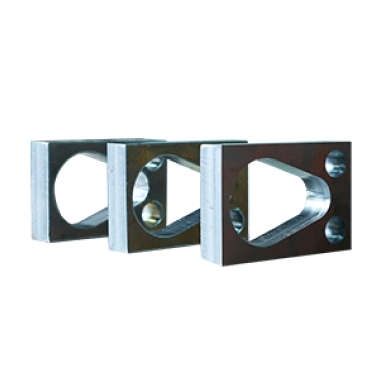

Find your machine

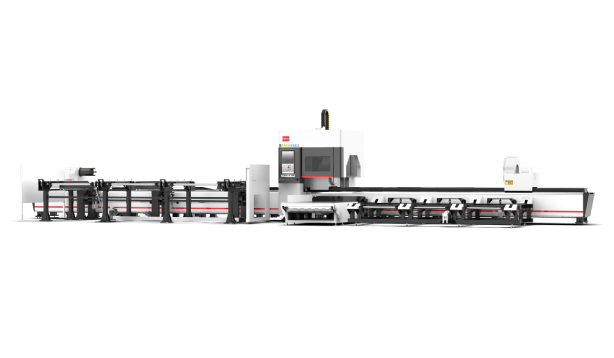

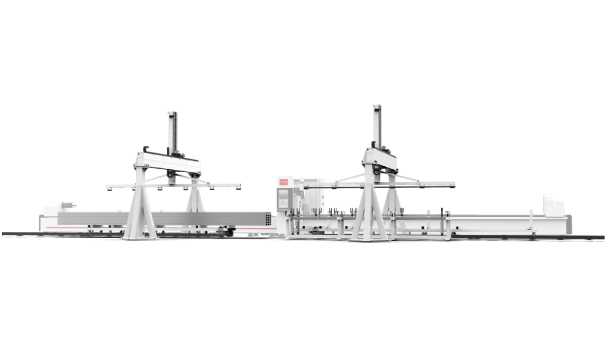

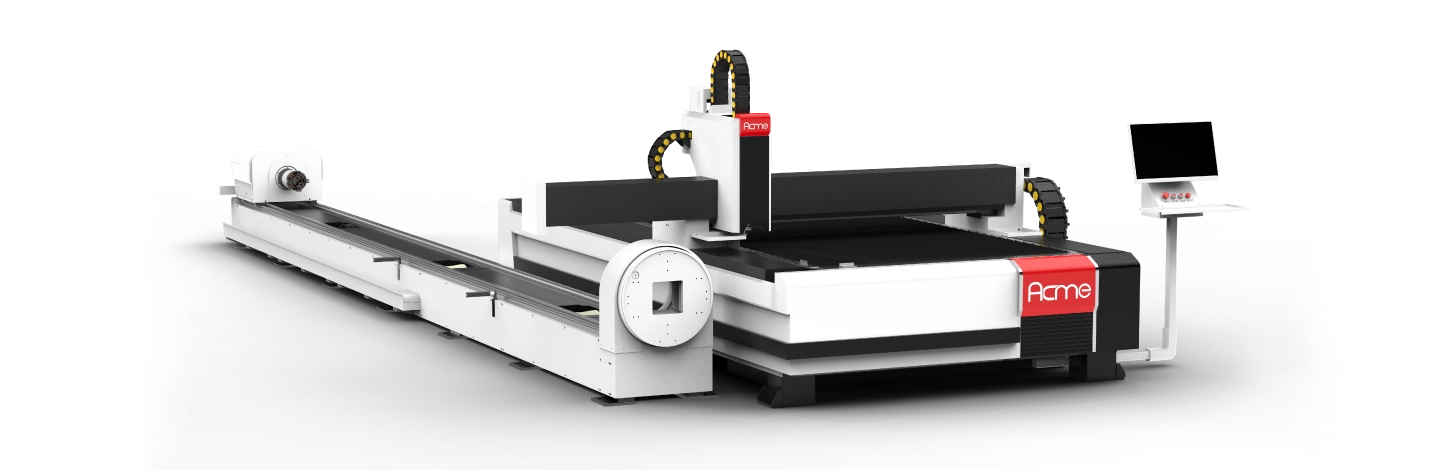

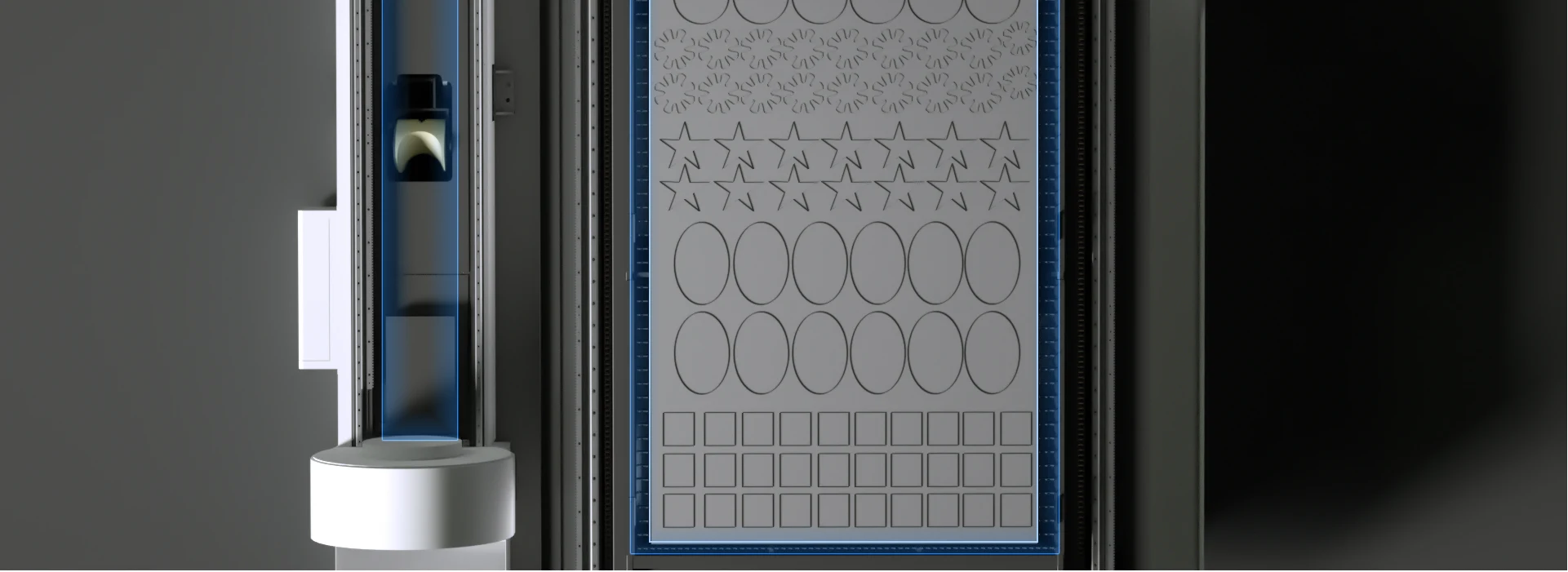

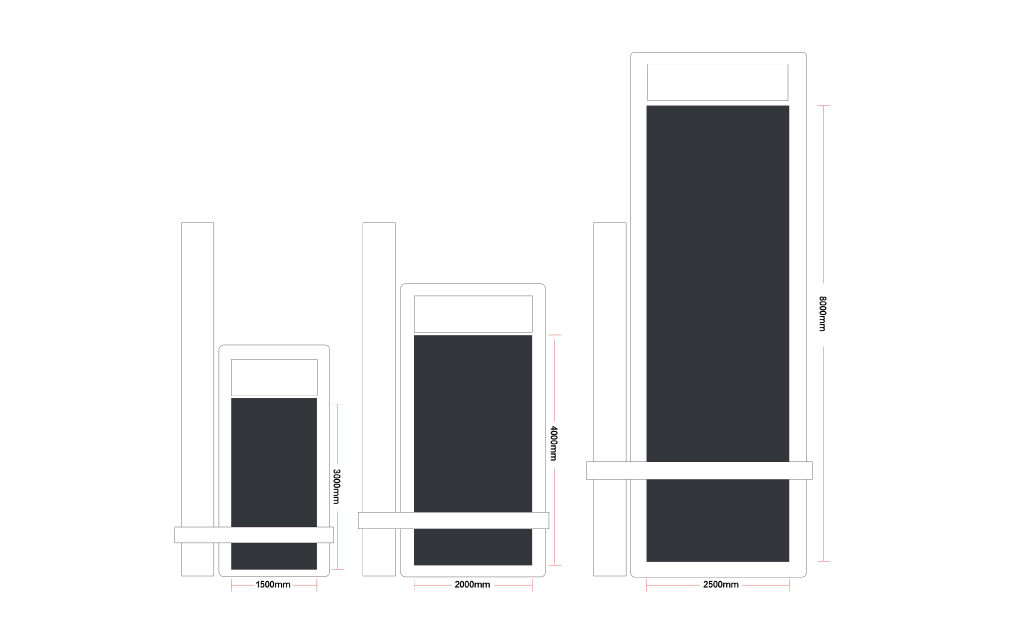

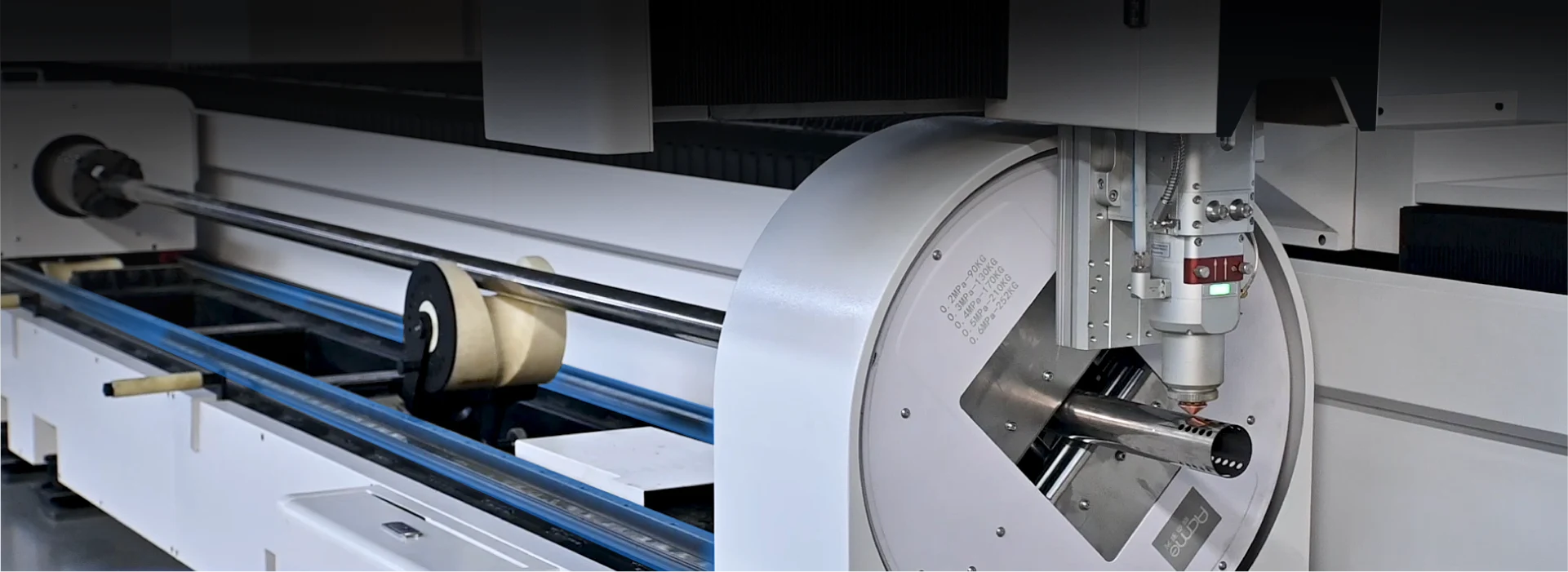

ST series machine bed is 3×1.5m as standard, chuck diameter is 120mm. Sheet cutting area: the length is 3m-12m, the width is 1.5m-3.5m. Chuck size is shown in the right figure.

please check your equipment information.

ST120

ST180

ST230

ST260

ST280

Reasons to choose Acme ST-series

1

High cost-effective

Specifically designed for the light and small pipe industries, it has significant advantages such as cost-effectiveness, compact design, easy operation, and low maintenance costs.

2

Space saving

Compact structure, small footprint, suitable for workshops or workplaces with limited space.

3

Easy operation

Concentrated functions and easy operation can help you get familiar with and master the operation of the equipment more quickly and improve work efficiency.

4

Easy maintenance

The parts and structure are relatively simple, and maintenance and maintenance work are relatively easy, which reduces maintenance costs and downtime.

5

Warranty

2-year maintenance warranty

Performance configuration

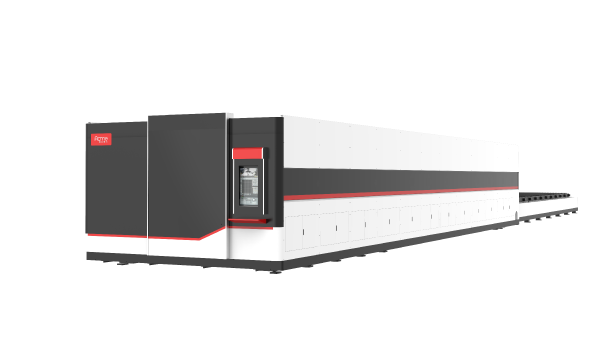

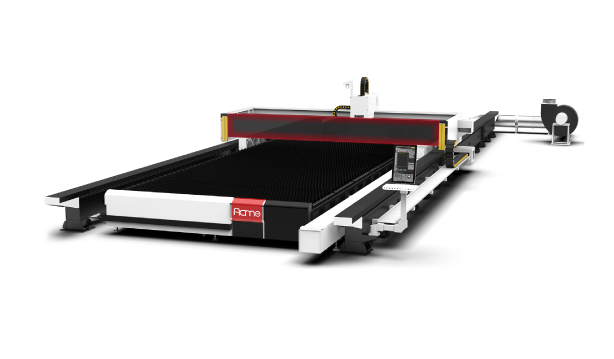

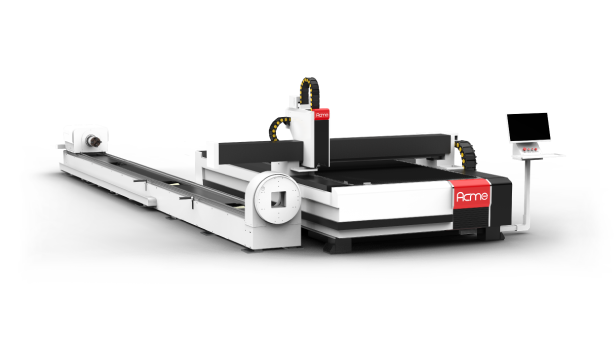

One machine Two function

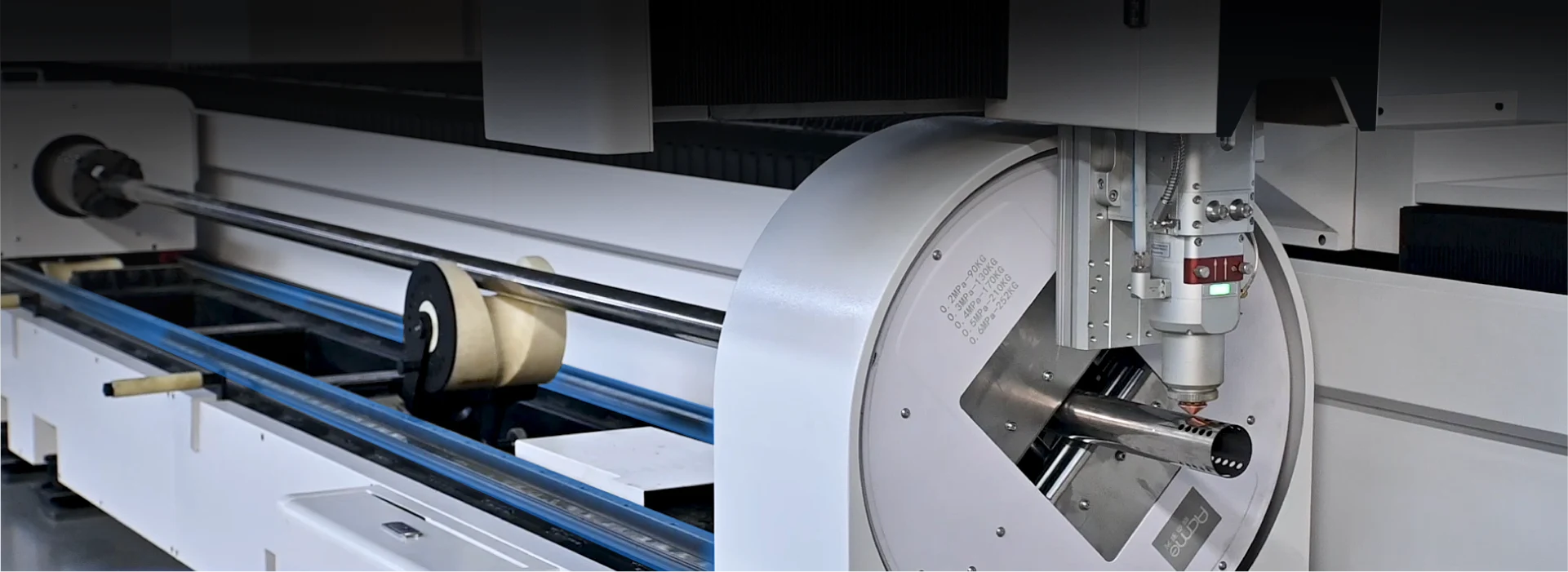

It can cut both metal sheets and metal pipes. Among the integrated tube-sheet machines, ACME has professional tube cutting capability.

Best configuration

Hiwin guide rails, YYC rack and pinion gears, France Schneider electrical components and accessories from well-known domestic brands. High-performance combination brings excellent experience and long-term returns.

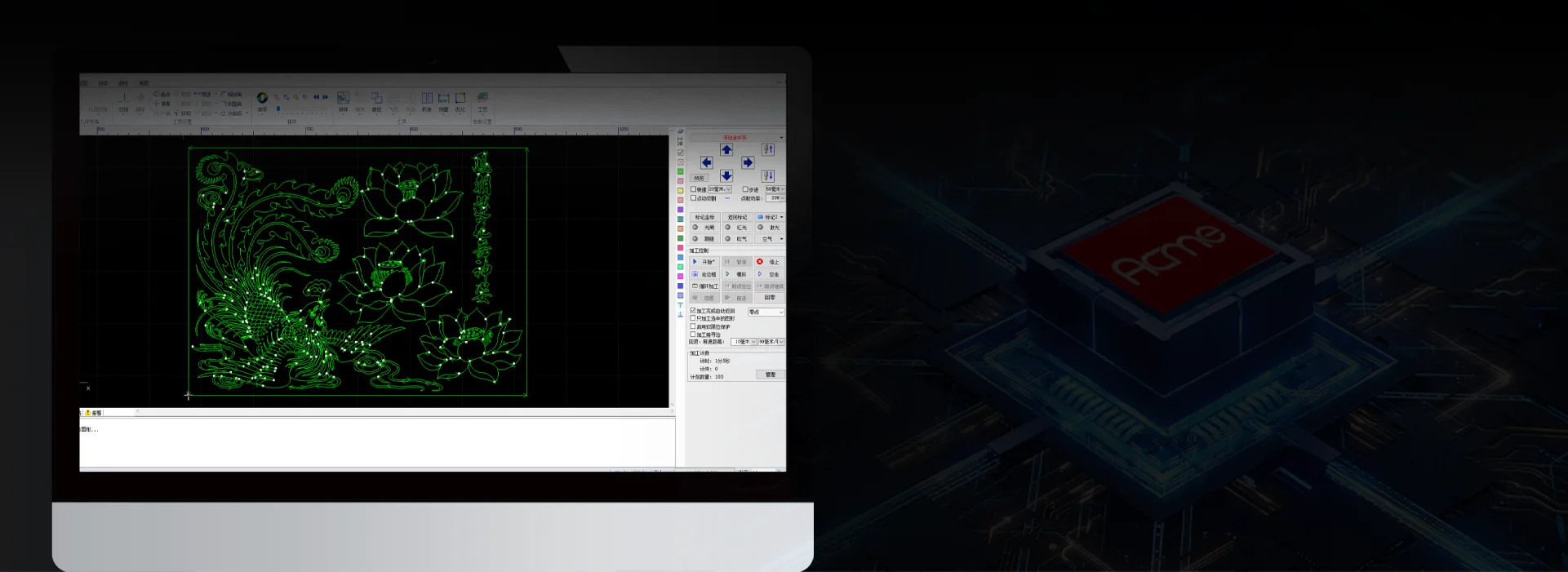

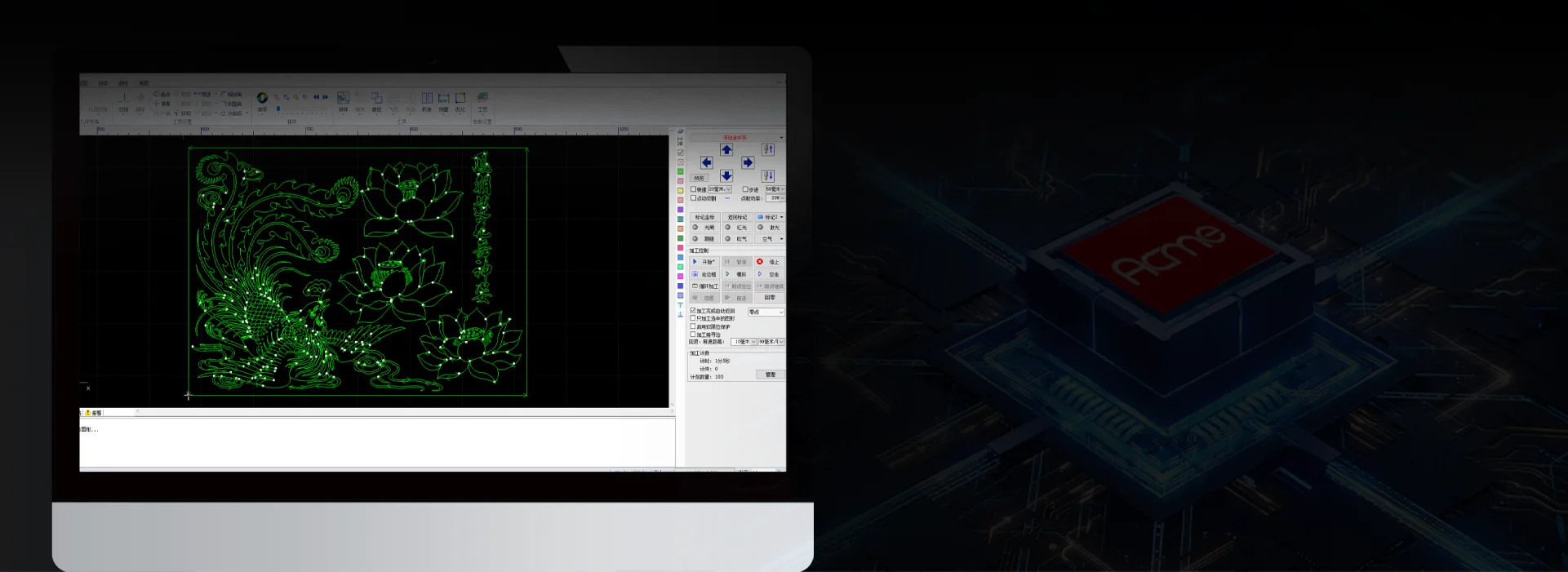

Bus system

The software has nesting function, as well as advanced functions such as

Innovative technology

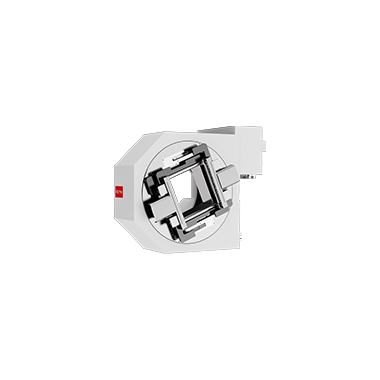

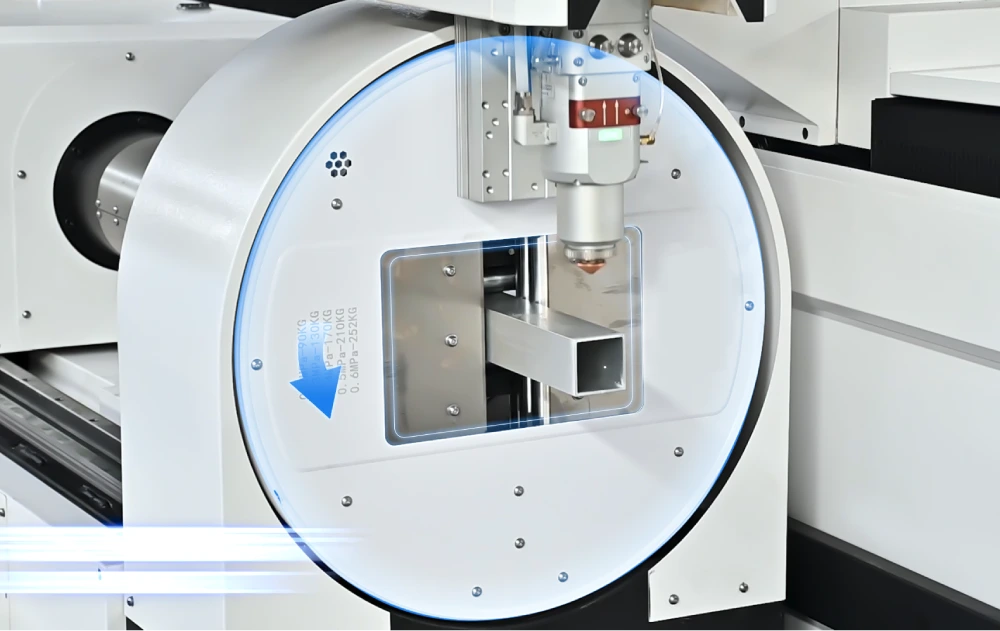

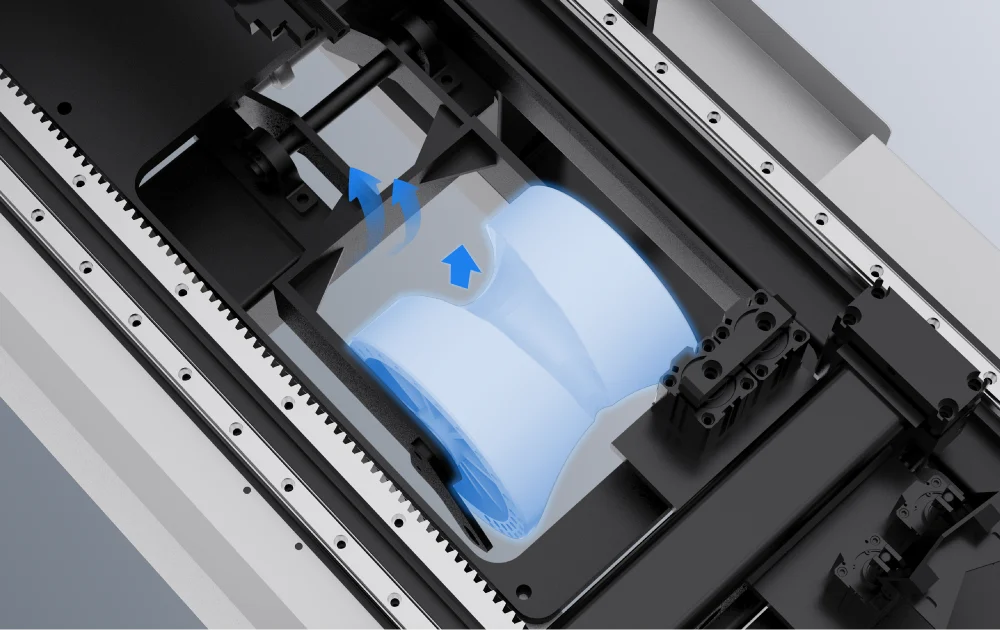

ACME’s chuck

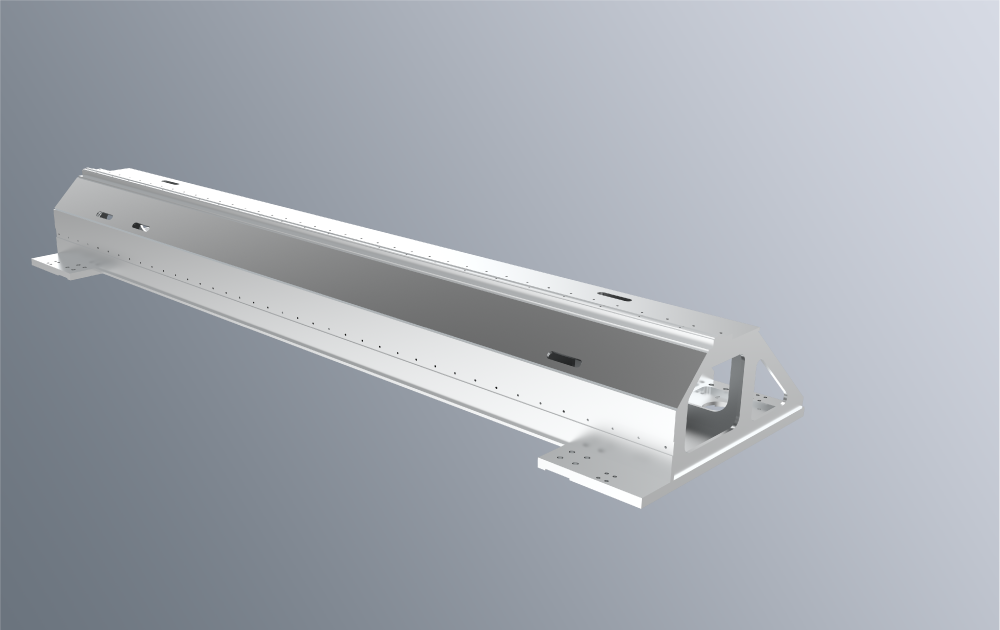

Aerospace Grade Aluminum beams

Stable support

ACME’s chuck

Eight-cylinder clamping, the clamping force is twice that of ordinary chucks;Square hole design, high passing capacity, cutting tubes within 8-250mm diameter;

Aerospace Grade Aluminum beams

Extrusion molding, no deformation, good toughness, light weight, corrosion resistance, low density, greatly improve your processing speed.

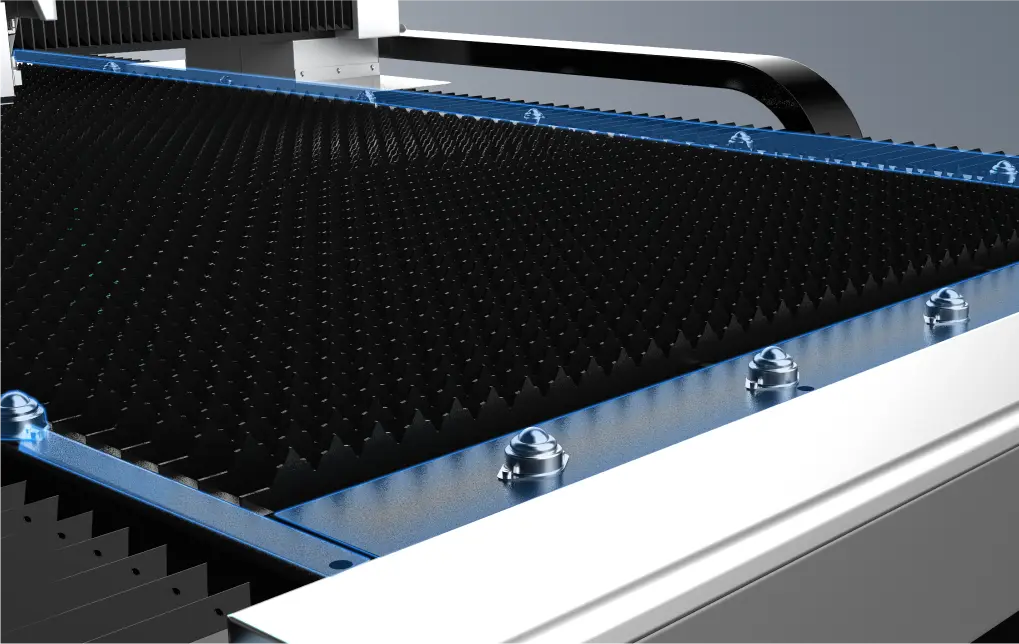

Stable support

It can automatically adjust as the rotation of the pipe, to protect the work-piece from damage caused by falling, and to achieve close support during the cutting process.

User-friendly design

The all-round design with ball bearings is easy to feed at the edge to avoid scratching the paper surface.

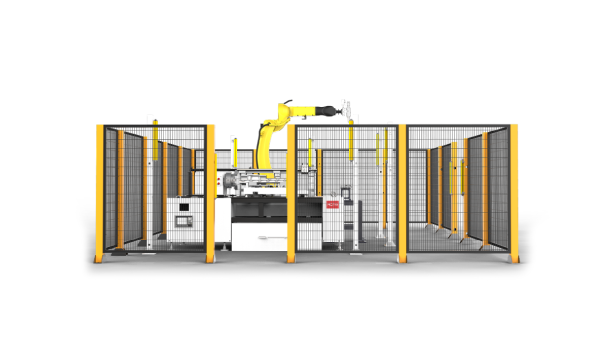

A variety of configurations support customization to meet your diversified production needs.

Remotely monitor operating status and fault information, improving maintenance efficiency, reducing unexpected downtime, and prolong the machine life.

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

What we can do

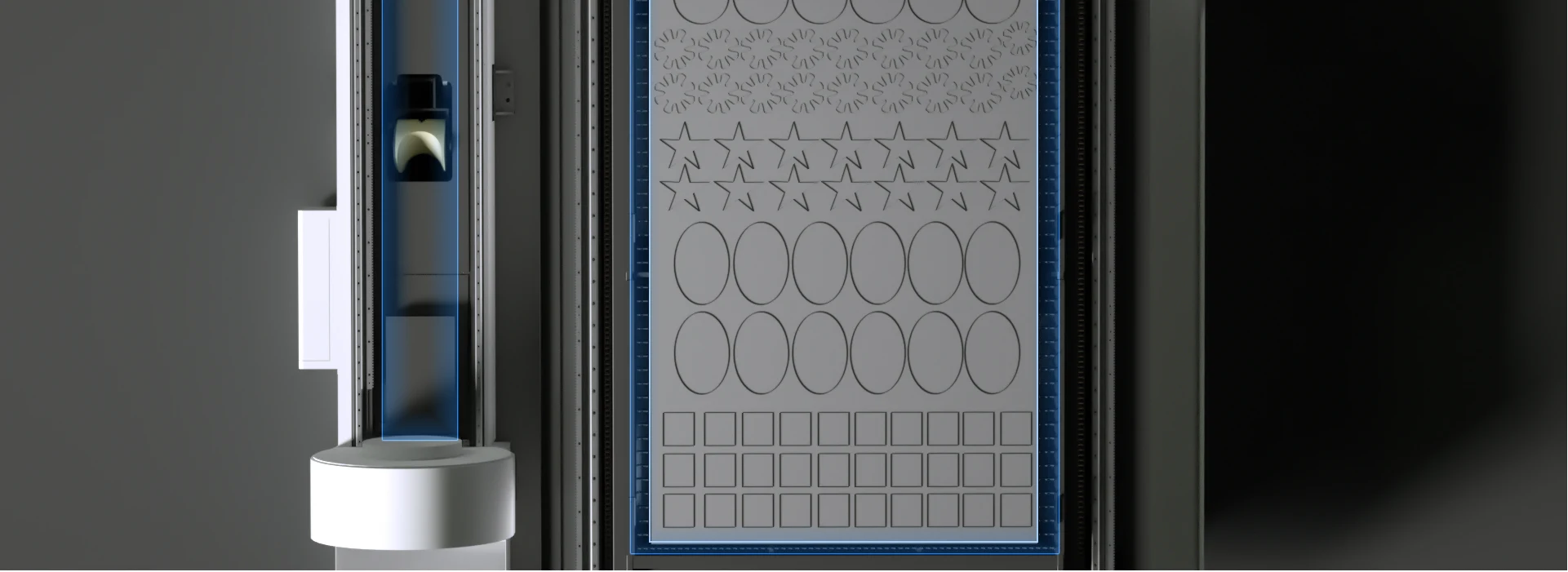

Co-edged cutting

Co-edged cutting can effectively reduce the number of piercing, reduce the average cutting path of a single part, improve overall production efficiency, and save material costs.

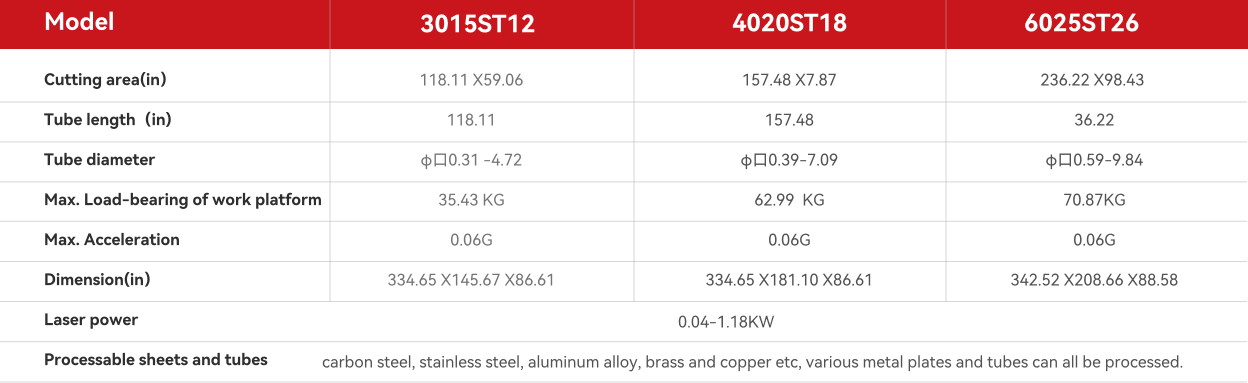

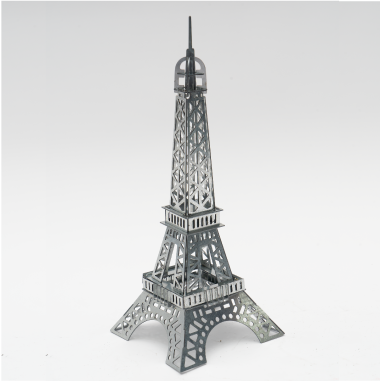

Sample display

Steel outsourcing processing Industry

Steel outsourcing processing Industry

Steel outsourcing processing Industry

Keep reading the Applications

industry cases

Machinery industry

It can cutting heavy and long workpieces can be whole perforated cut off

DISCOVER MORE

Elevators manufacturing

It can adapt to any metal pipe within 1.5 tonnes, all kinds of complex shapes and special materials processing needs.

DISCOVER MORE

Steel market external processing

No need to dismantle and replace the jaws to improve production efficiency.

DISCOVER MORE

Shipbuilding

Good cutting section, improve welding quality and increase structural strength

DISCOVER MORE

"Since purchasing ACME laser machine, our elevator production efficiency has been greatly improved, and the product quality has also been significantly improved. The cutting effect is exquisite and the processing flexibility is high, which has truly solved our problems!"

High-quality processing

READ THE FULL STORY

"Since we purchased these three machines from ACME, we have received more and more orders. In general, the quality, delivery time and output have all improved, and we can meet all customer requirements perfectly. Customers are increasingly trusting us. In addition, ACME has changed our original production model. Currently, we can provide customers with one-stop services, from purchasing raw materials, cutting pipes, welding to galvanizing. With more and more orders, we plan to purchase another one"

Innovative production methods for customers

READ THE FULL STORY

“More than 70% Chinese commercial fitness equipment comes from our vicinity. There are 2,500 fitness equipment factories in our area. Among them, more than 50% use ACME laser machines. ACME has developed together with the fitness equipment industry. They understand our industry needs. A lot of ACME core technology engineers are not available in other bidding manufacturers, which is also an important reason why we chose ACME.”

A large customer group

READ THE FULL STORY

"Now we have two sets machine from ACME. With the recognition of customers and the increasing orders, we plan to purchase one machine again. ACME Laser is my first choice. Because during the six-month using, machine works very well, when having something to ask, ACME team responded and solved promptly. For example, if we need some accessories, they will send from the headquarters immediately. With ACME engineers, we are like friends, communication is very smooth!"

We are like friends with ACME engineers

READ THE FULL STORY

Elevator manufacturing industry

Steel market external processing,

Fitness equipment industry

Outsourcing processing industry