What we can do

1

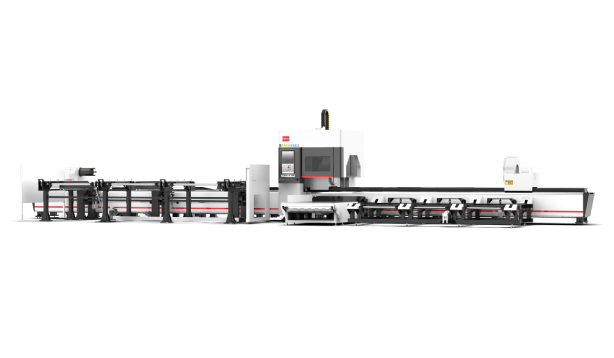

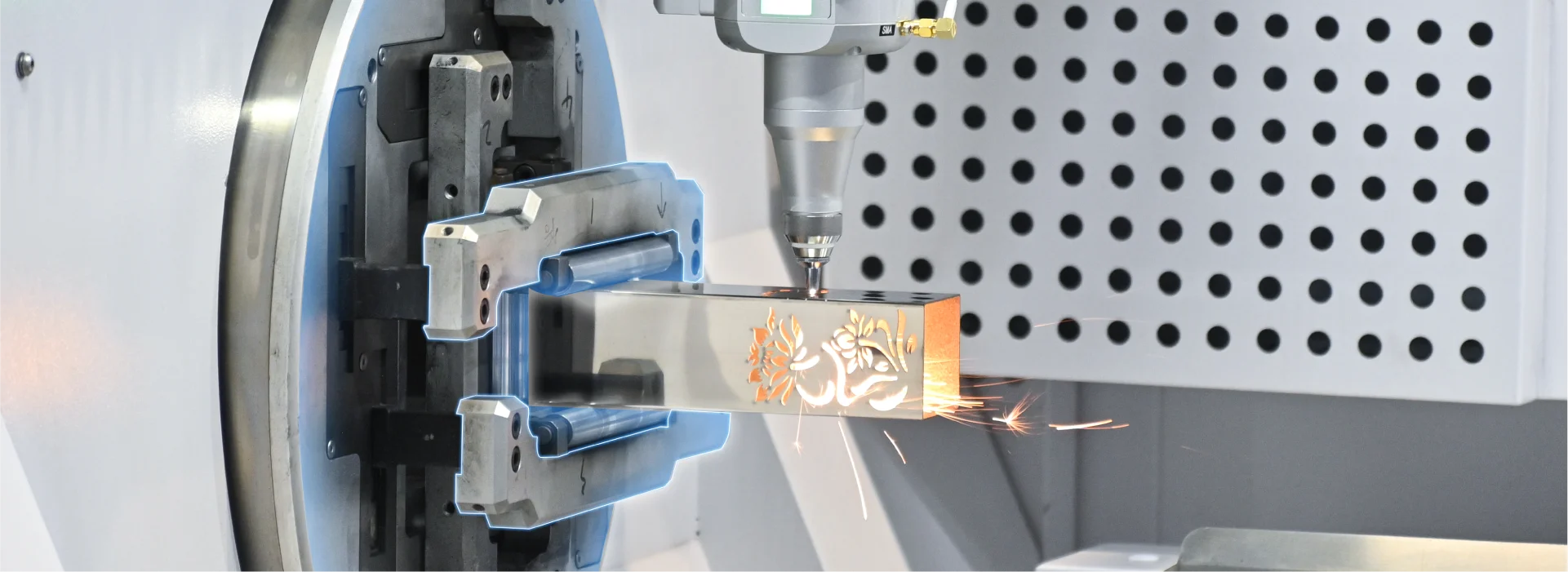

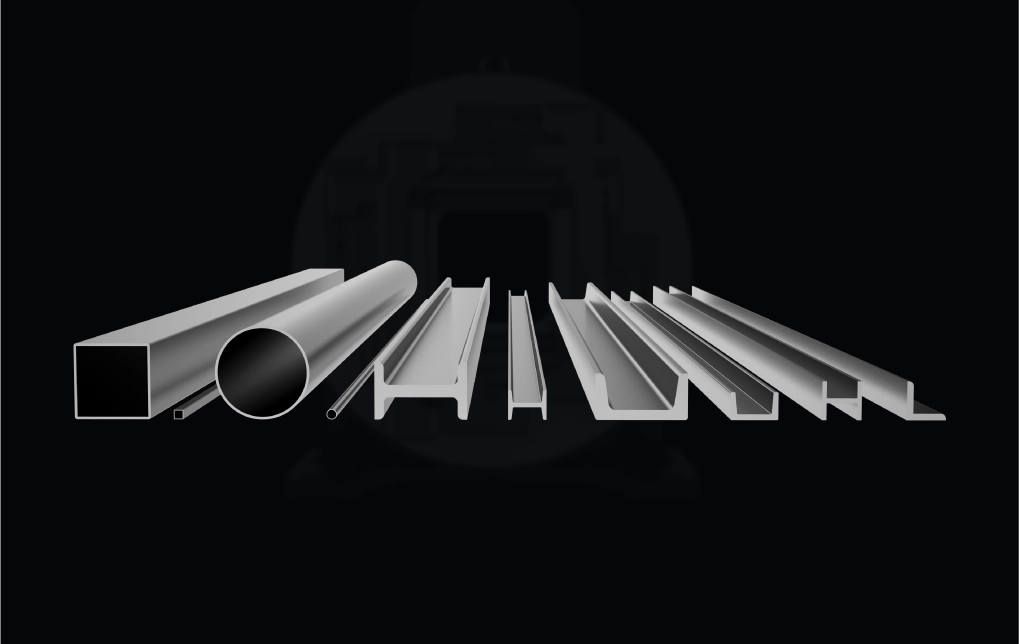

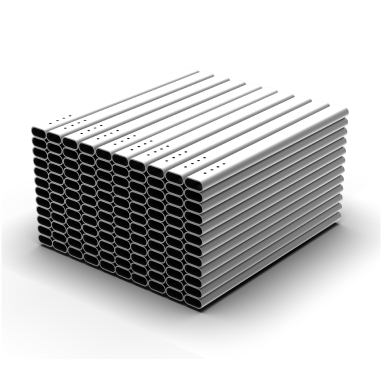

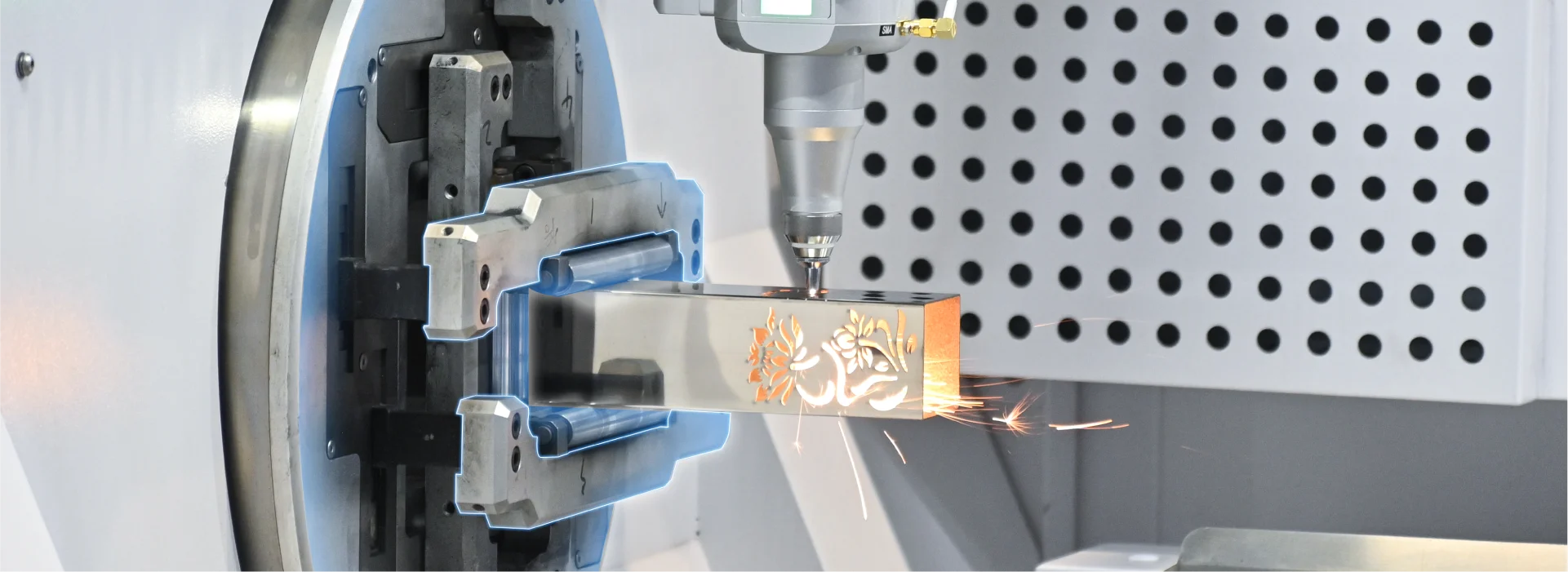

Cutting ability

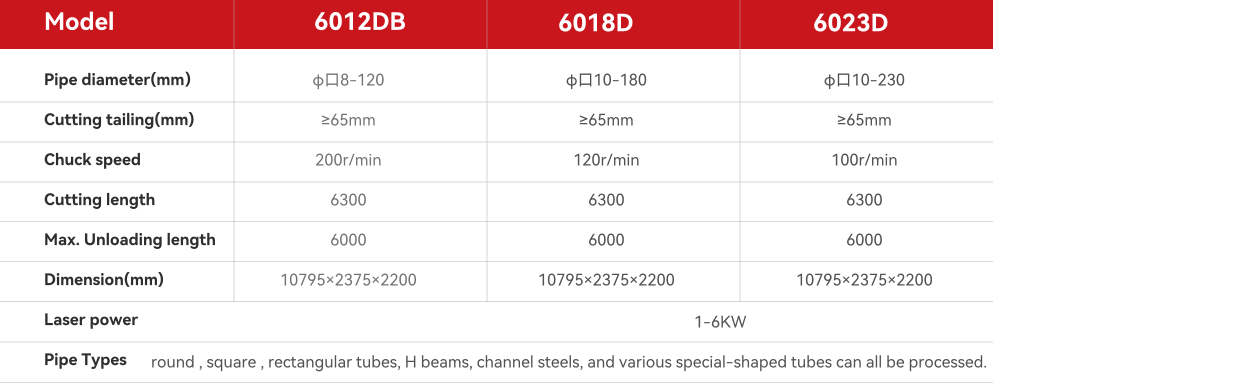

D-Series top selling tube laser cutting machine, can cut any metal Tubes, with the length of 6m, the diameter 8-250mm, and the weight 300kg or less

2

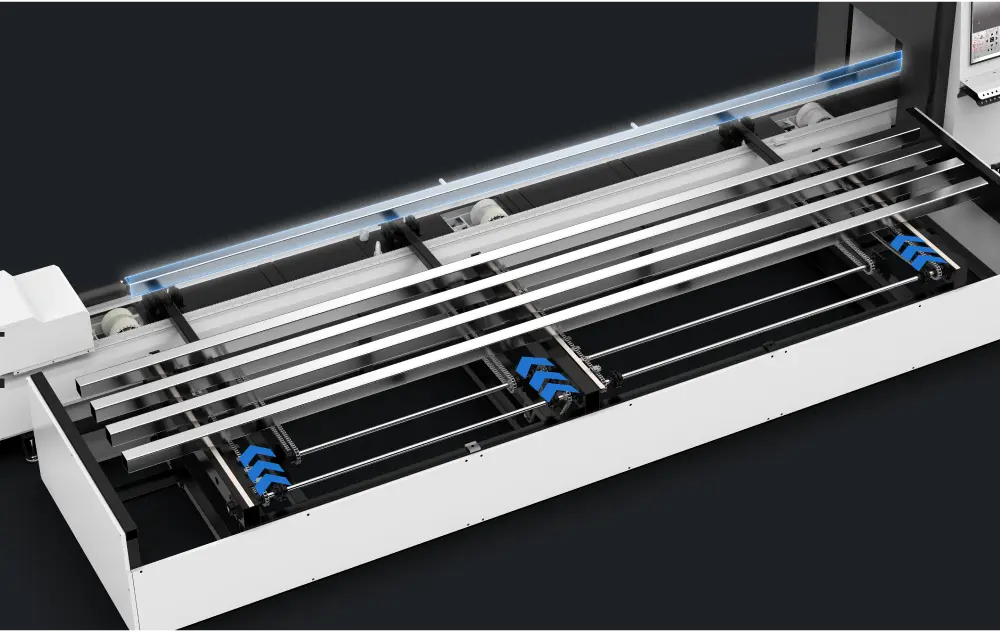

Small and high-speed chuck

200r/min, fast cutting speed; small tail material technology,High material utilization rate

3

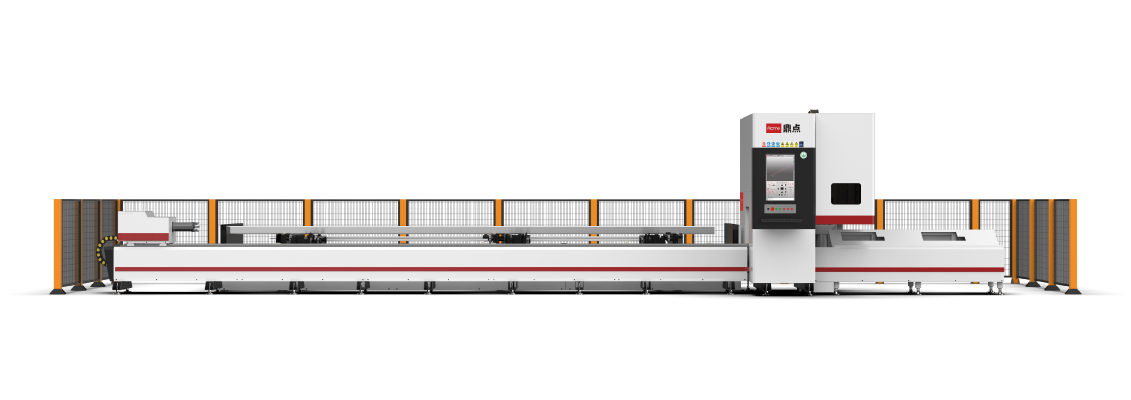

Gantry structure

minimize beam vibration to ensure cutting accuracy, no deformation after long-term use

4

High cost-effective combination

compact design, reduced floor space; easy installation and simple operation; high-quality processing, extremely low operating costs and super high adaptability;

5

Maintenance

2-year maintenance warranty

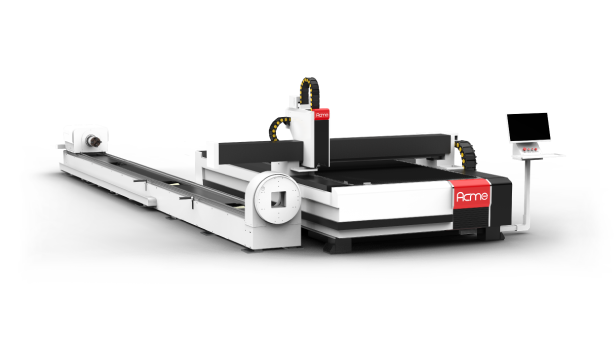

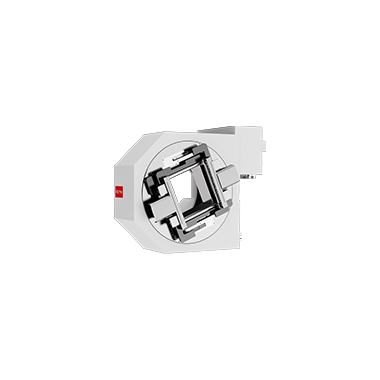

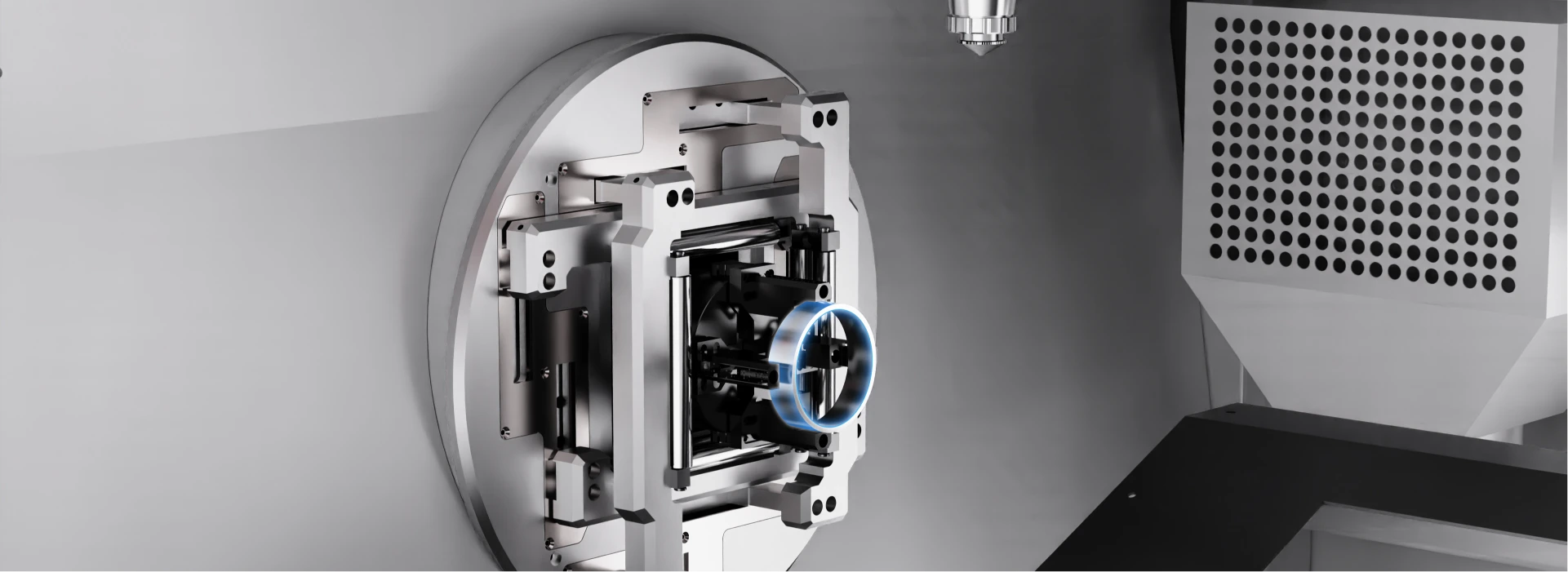

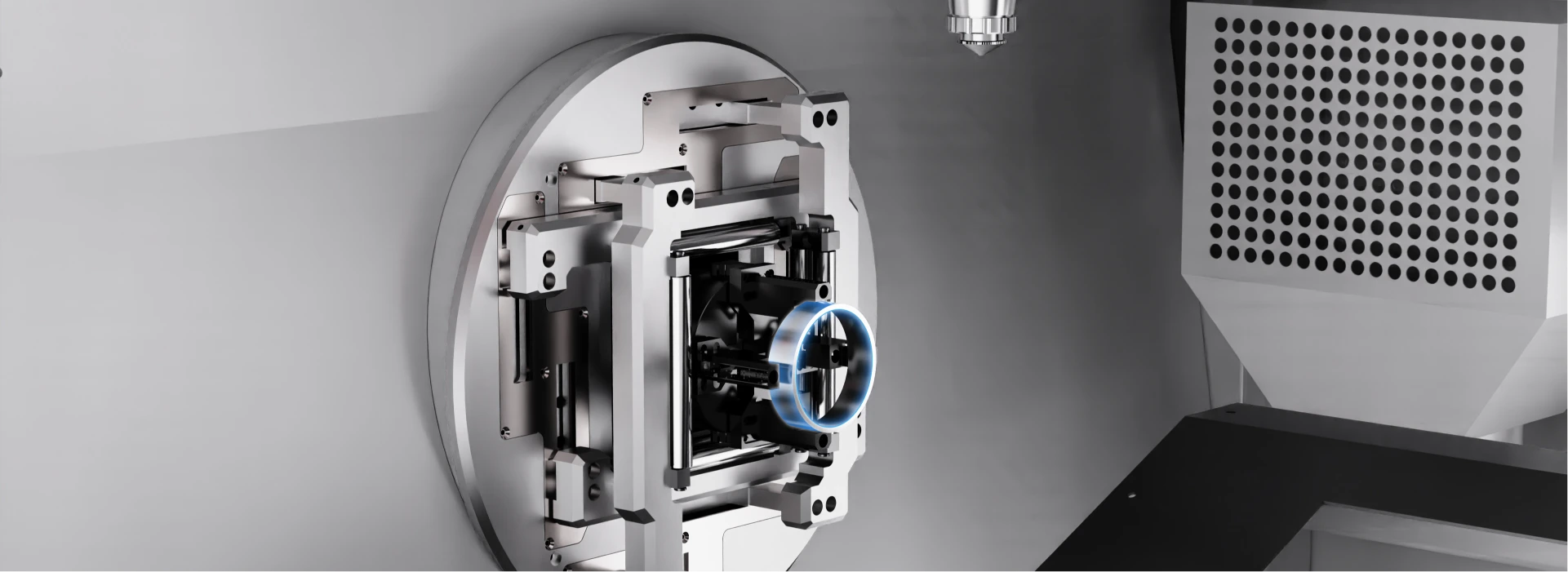

Chucks

Double roller claws

Stably clamp thin Tubes to prevent deformation of work-pieces, solving processing problems for you;

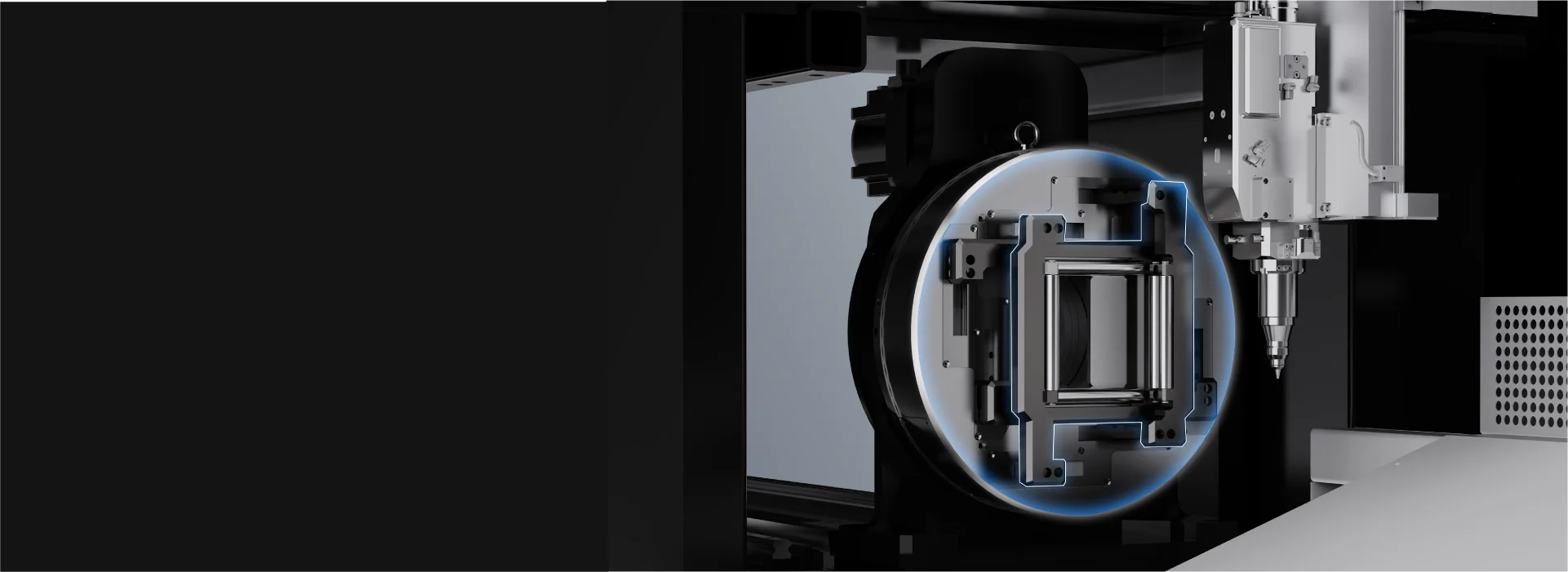

Short tailing technology

The extended design of rear chuck can enter into the front chuck, to realize small tailing cutting.

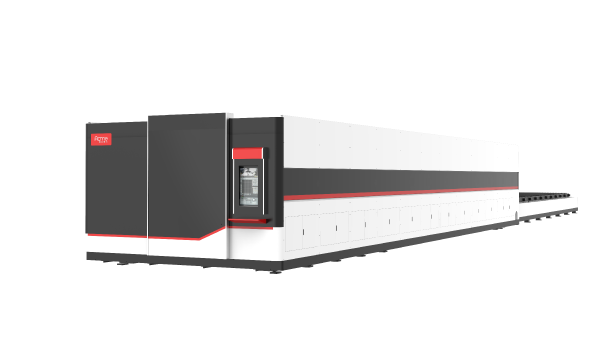

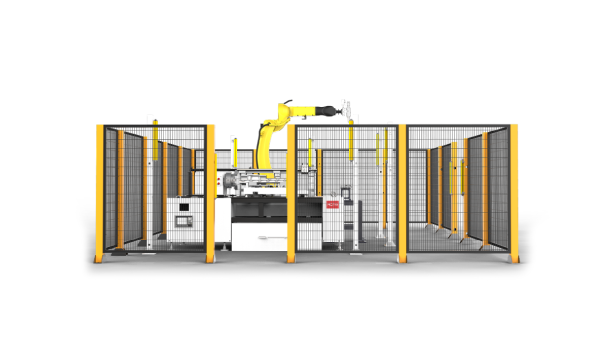

Fully enclosed design

The chuck is fully sealed, no slag and dust are fed, avoiding machine fault and low precision;

Innovative technology

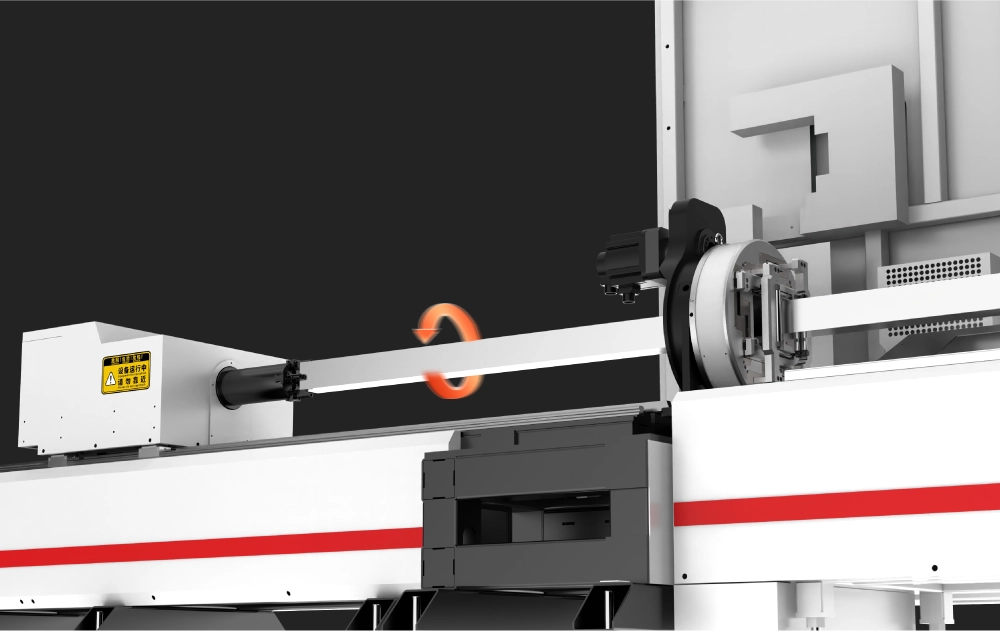

High dynamic performance

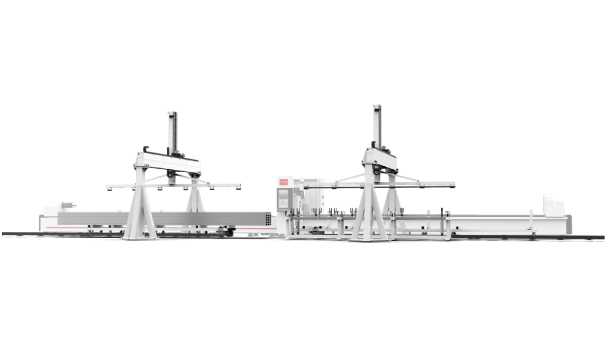

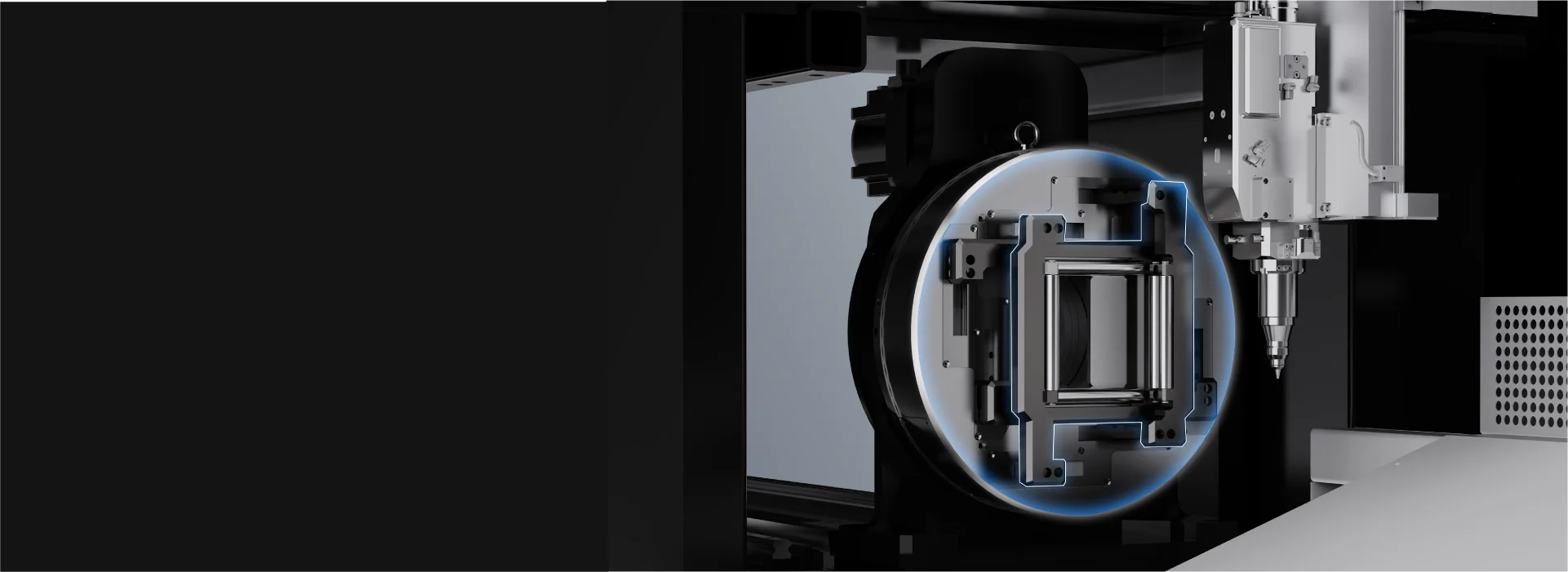

Gantry structure

Light type loader

High dynamic performance

120 model, chuck moving speed 110m/min, rotation speed 200r/min, acceleration 1.5G, creating higher production efficiency for you;

Gantry structure

Minimizes beam vibration to ensure cutting accuracy, no deformation for long-term use;

Light type loader

Light loader is optional, compact design, high cost performance; one person can watch over multiple devices, saving labors and improving efficiency.

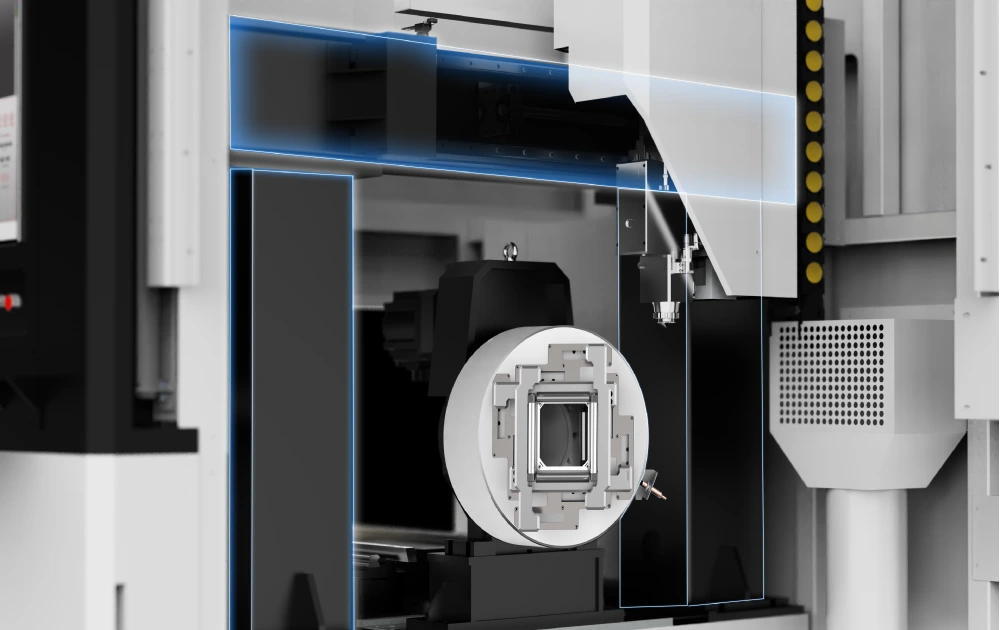

User-friendly design

The control cabinet, laser source and main machine body are integrated to reduce the floor space, facilitate installation and maintenance, and don’t require air-conditioning rooms, improve space utilization, and reduce operating costs. It’s very suitable for mass production of small-diameter Tubes and profiles;

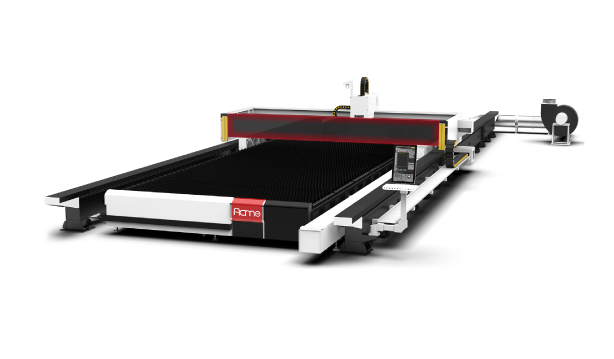

Support various Tubes cutting

Complete cutting functions, with nesting software, to achieve common edge cutting, saving time and materials;

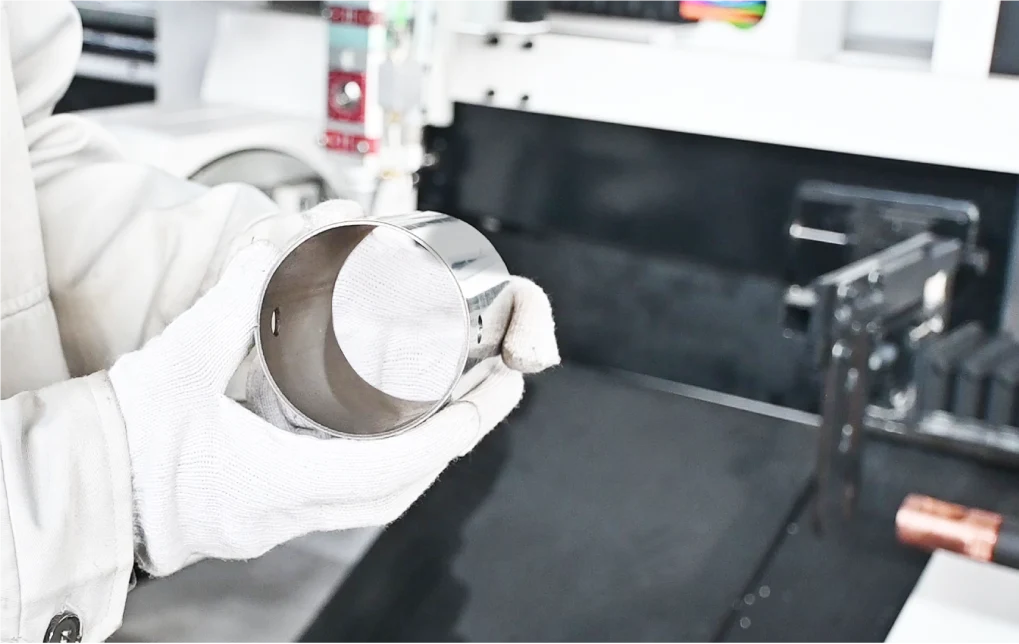

Removal of dust and debris on the inner wall of Tubes, smoother cutting tube inner wall , and saves one slag removal processes. Excellent smoke exhaust effect, creating a clean working environment for you.

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

Reasons to choose Acme D-series

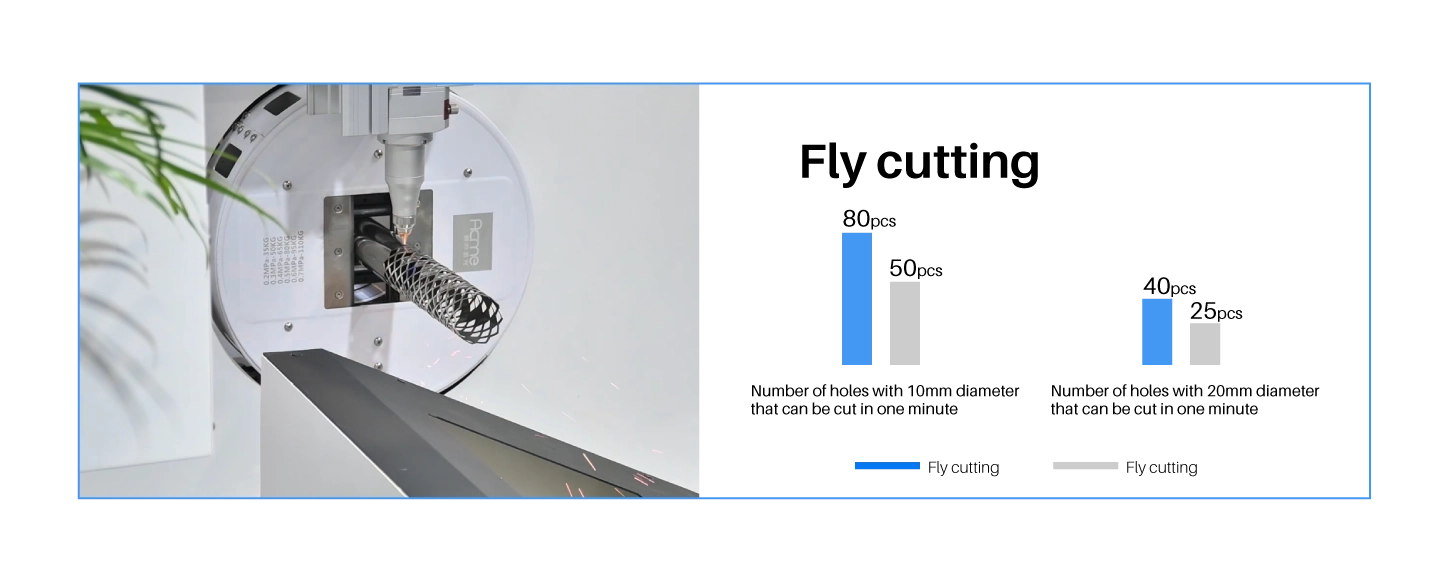

Fly cutting

Generate flying cutting lines with one click, quickly cut, reduce frequent acceleration and deceleration processes, and more efficient to cut intensive graphics.

Sample display

External processing industry

School appliance industry

Keep reading the Applications

industry cases

Fitness equipment

Material utilisation can be increased by means of nesting software.

DISCOVER MORE

Guardrail industry

Only needs to input the programming programme according to the demand to cut accurately

DISCOVER MORE

Science and Education Office

120mm high-speed chuck 200 rpm, fast cutting.

DISCOVER MORE

Elevators manufacturing

It can adapt to any metal pipe within 1.5 tonnes, all kinds of complex shapes and special materials processing needs.

DISCOVER MORE

"Now we have introduced a number of ACME laser tube cutting machines. During , we found that the efficiency is more than 20% higher than that of peers, the failure rate is also low, the operation is simple, and the maintenance is convenient. ACME's technicians trained for two hours, and our workers can operate independently. The after-sales service is even more considerate, the after-sales staff responds quickly, and the problem is solved efficiently. In short, ACME laser tube cutting machine is easy to use and economical."

The price is nice and it’s widely used

READ THE FULL STORY

At present, Dong Fang Hao Yu has purchased two professional laser tube cutting machines LT-9017ES from ACME, they have been serving good operation for customers for two years. These two devices have brought great convenience to the company's production and can meet the various photovoltaic bracket columns cutting needs, which is basically consistent with ACME's promise at the time.”

Brought great convenience

READ THE FULL STORY

"The heavy duty side-mounted machine of ACME, both in terms of performance and processing quality, can stand the test of time!"

improving labor production efficiency

READ THE FULL STORY

"Since purchasing ACME laser machine, our elevator production efficiency has been greatly improved, and the product quality has also been significantly improved. The cutting effect is exquisite and the processing flexibility is high, which has truly solved our problems!"

High-quality processing

READ THE FULL STORY

New Energy Industry

Photovoltaic Bracket Industry

Heavy machinery industry

Elevator manufacturing industry