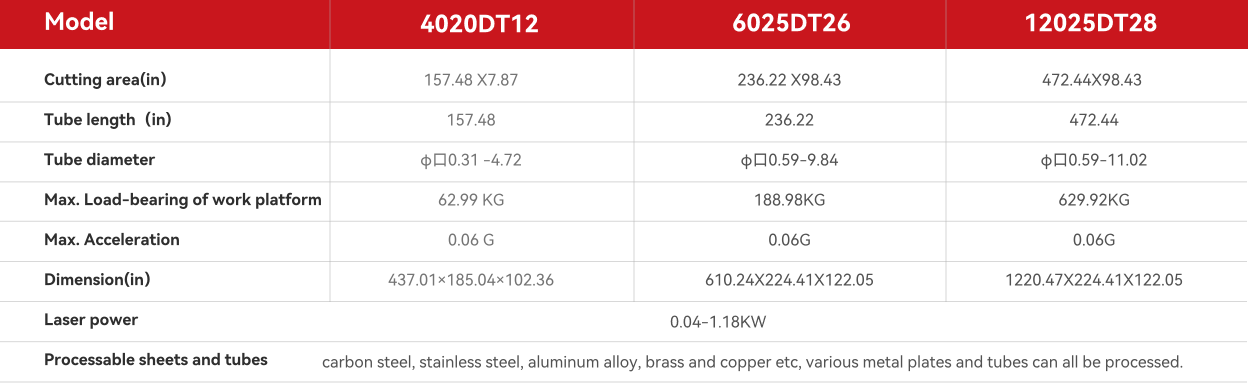

Find your machine

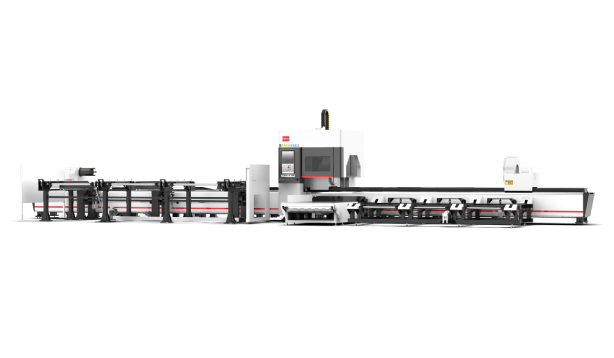

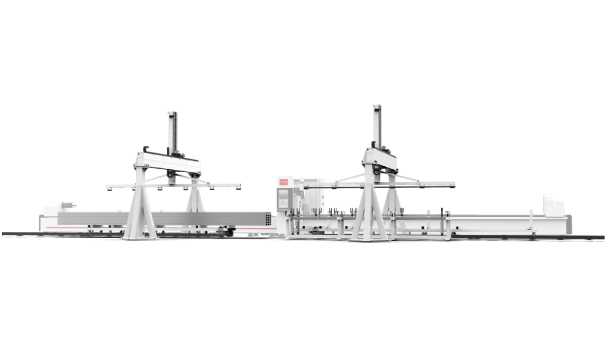

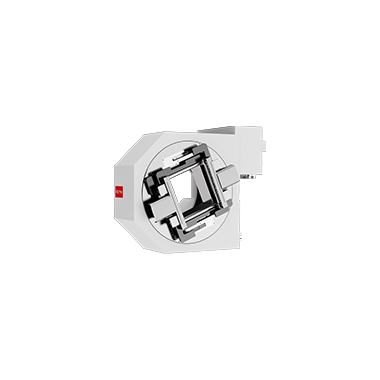

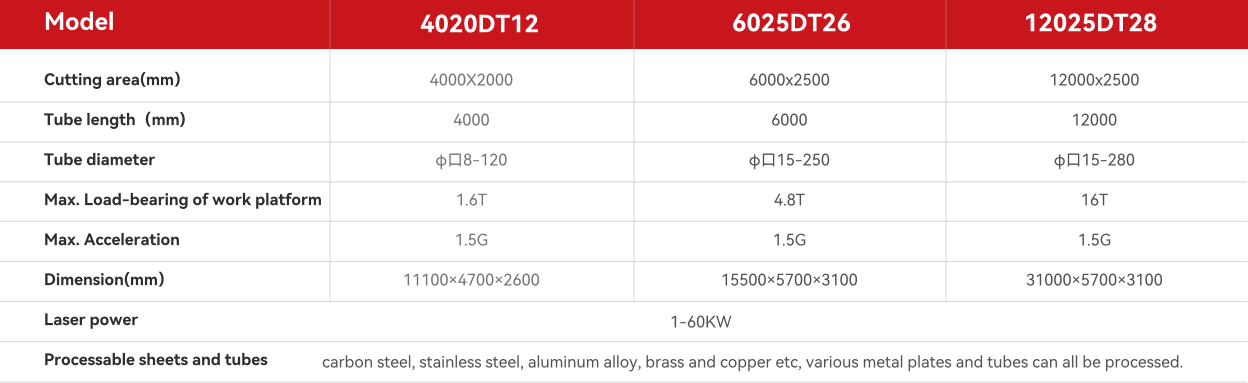

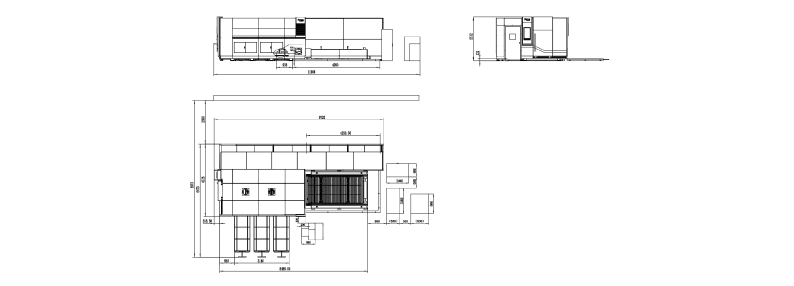

DT series machine size is 3×1.5m as standard, chuck diameter is 260mm. Sheet cutting area: the length is 3m-12m, the width is 1.5m-3.5m. Chuck size is shown in the right figure.

please check your equipment information.

Reasons to choose Acme DT-series

1

Saving labor costs

One device can complete the cutting of two materials, effectively reducing the need for operators and reducing labor costs.

2

Multi-function integration

Integrate sheet cutting and tube cutting into one device, saving procurement costs and footprint.

3

Efficient and flexible

Able to quickly switch between sheets and pipes, greatly improving production efficiency, and can flexibly respond to different types of processing tasks.

4

High-precision cutting

Whether it is sheets or pipes, high-precision cutting can be achieved, effectively ensuring the consistency and stability of processing quality.

Performance configuration

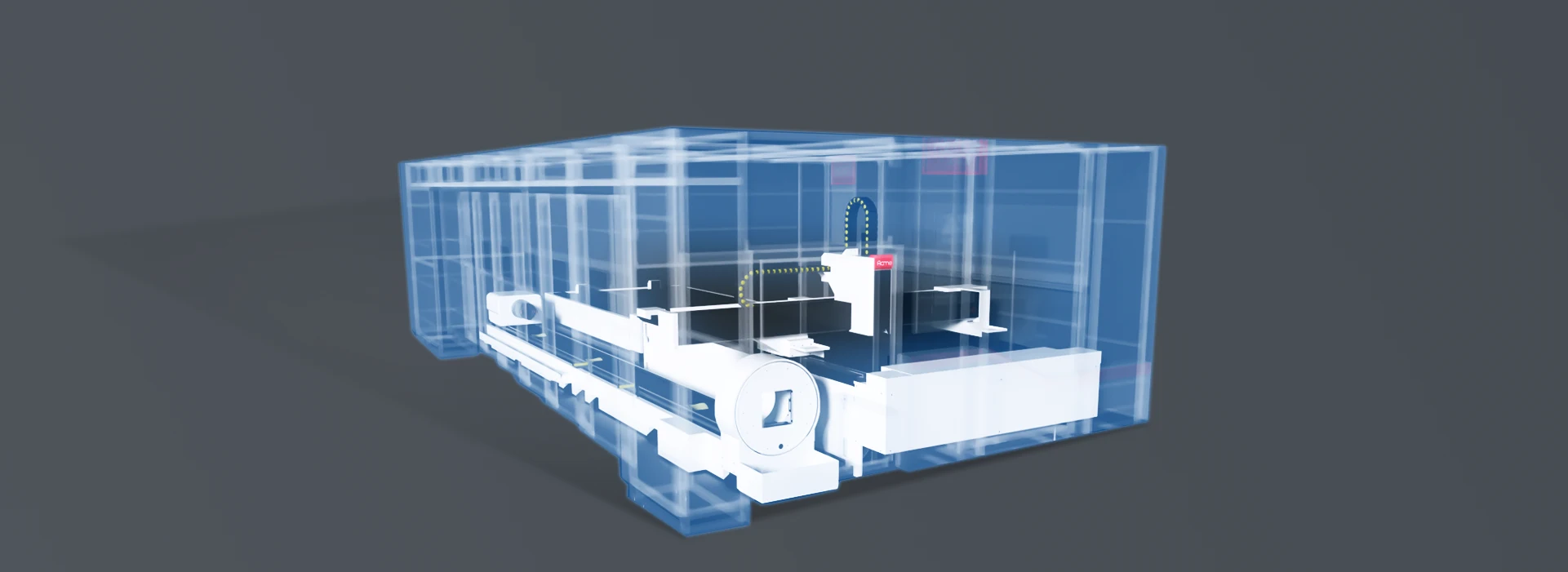

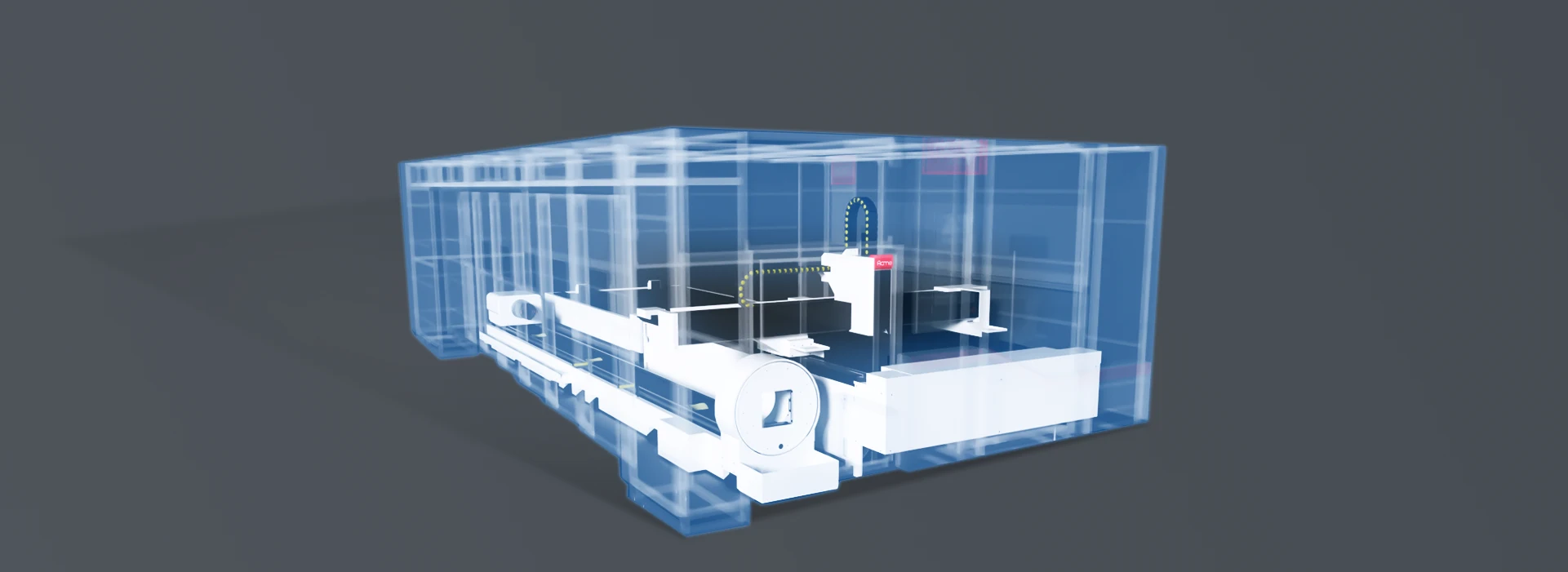

One machine two function

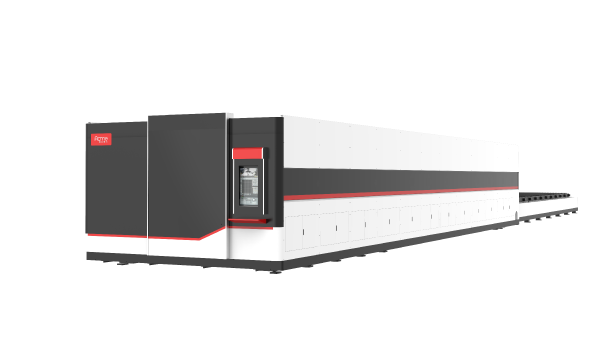

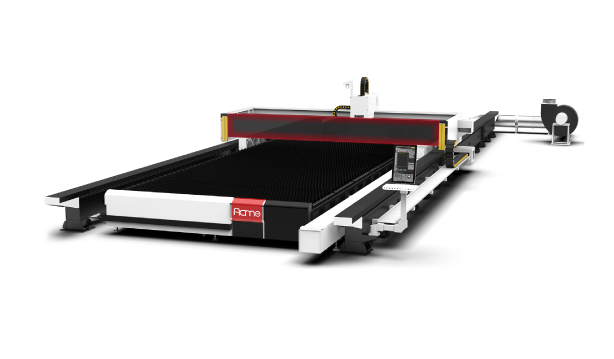

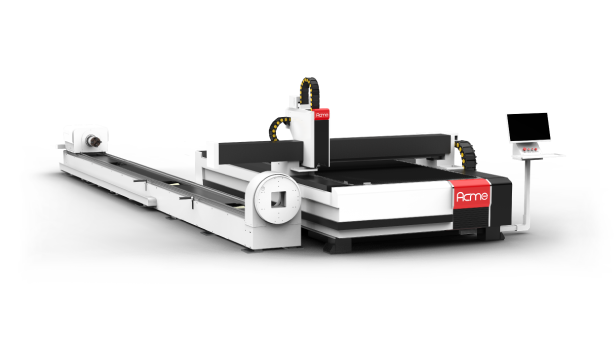

It can cut both metal sheets and metal pipes. Among the integrated tube-sheet machines, ACME has the best tube cutting capability.

Excellent dynamic performance

Dual servo motors are equipped with extruded aluminum beams, with a maximum moving speed 115m/min and a maximum acceleration of 1.5G, which can efficiently cut sheets of different thicknesses;

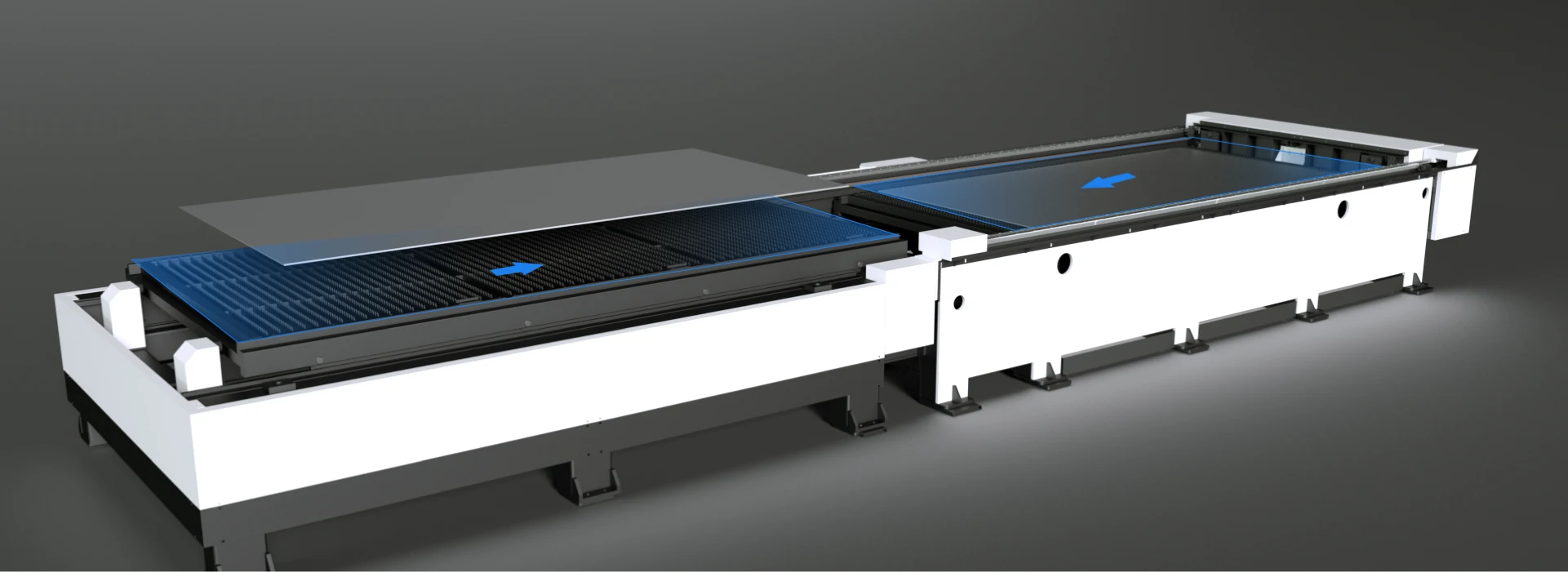

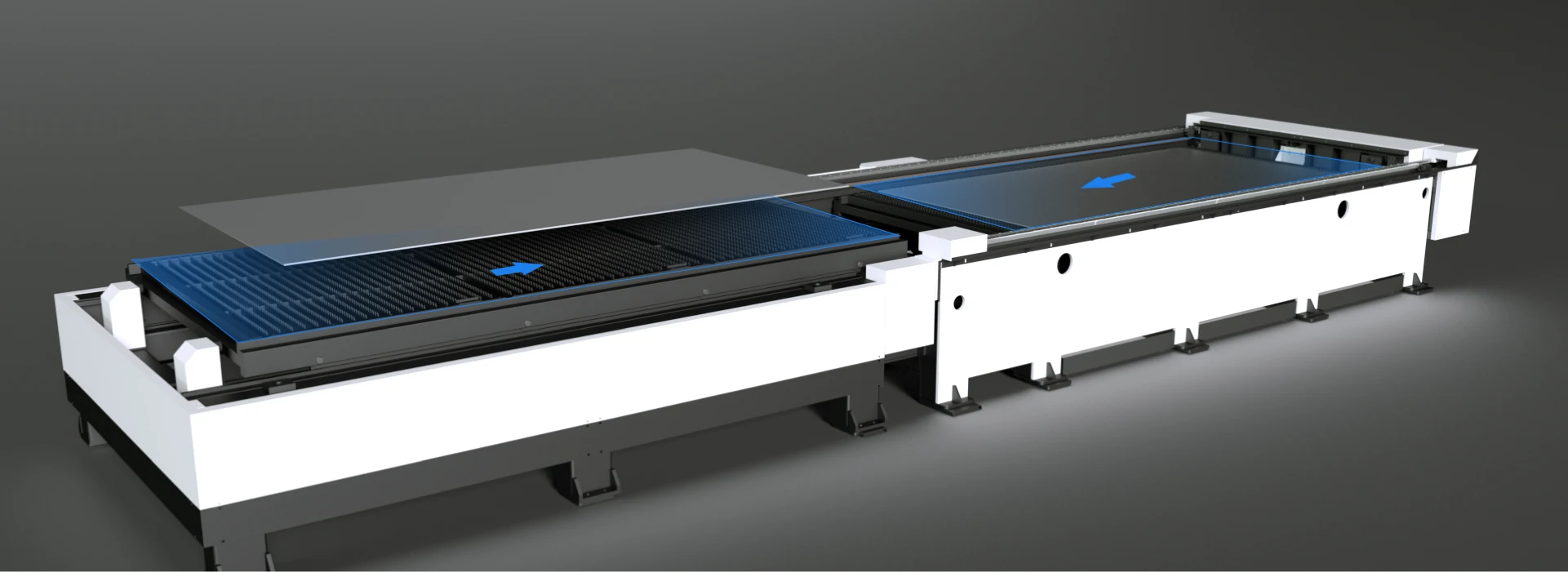

Exchangeable working platform design

15S fast exchange reduces the waiting time for cutting and loading, and effectively improves work efficiency by more than 30%. Designed for large production capacity, it converts high-speed feeding into sheet output;

Innovative technology

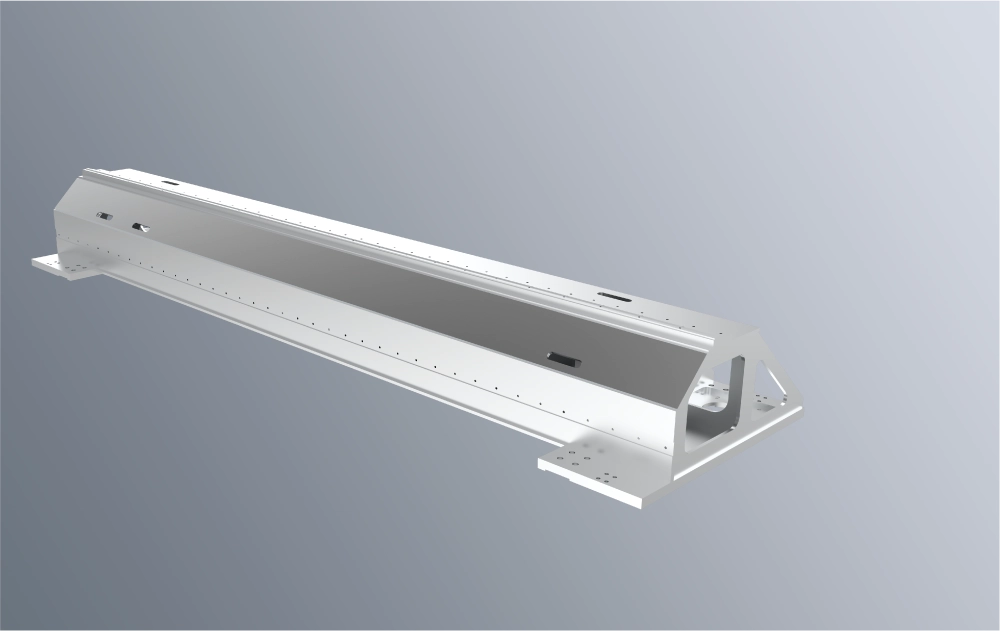

Aerospace grade aluminum beams

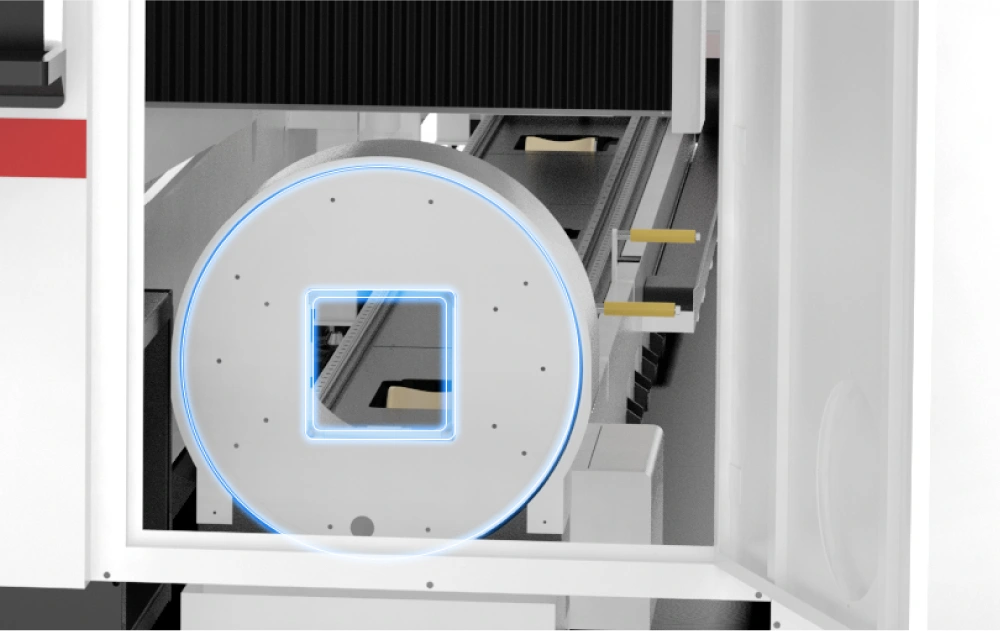

ACME’s chuck

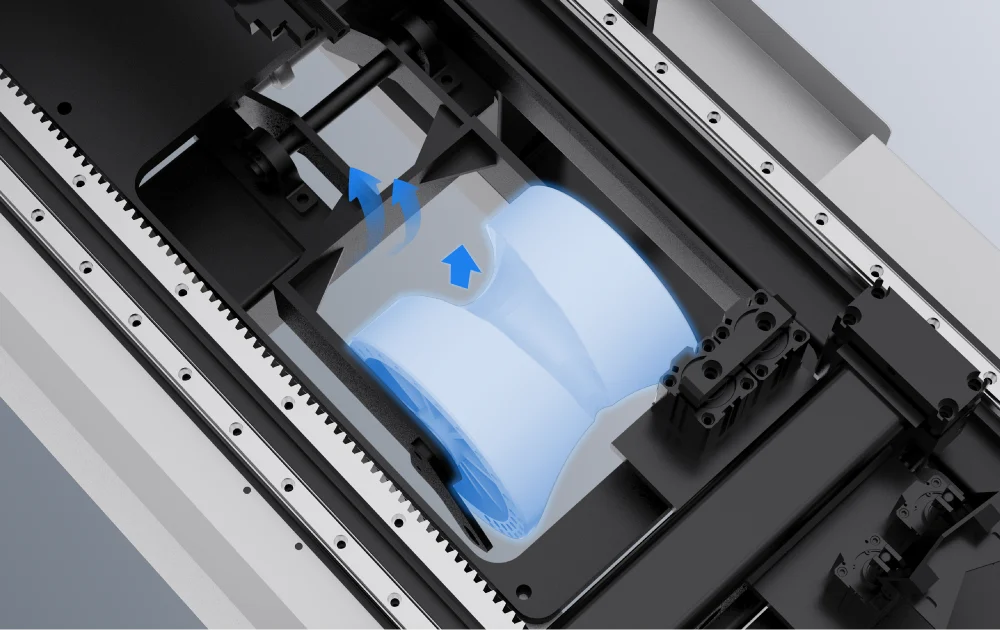

Stable support

Aerospace grade aluminum beams

Extrusion molding, no deformation, good toughness, light weight, corrosion resistance, low density, greatly improve your processing speed.

ACME’s chuck

Eight-cylinder clamping, the clamping force is twice that of ordinary chucks;Square hole design, high pipe passing rate, can batch process any metal pipe with a diameter of 8-250mm;

Stable support

It can automatically adjust according to the rotation of the pipe to protect the workpiece from damage caused by falling and achieve close support during the cutting process.

User-friendly design

Real-time air pressure control

Intelligent closed-loop control can realize real-time detection and adjustment of air pressure, improve the stability of the cutting process, and ensure production quality and efficiency

Intelligent nozzle replacement

Automatically replace nozzles according to different sheets and thicknesses

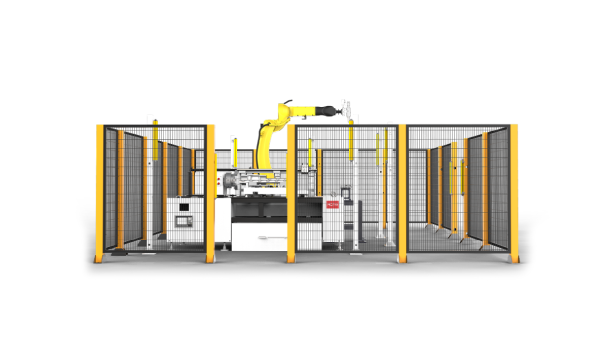

All-round protective cover design, in line with EU CE standard certification, more environmentally friendly and safer to operate;

Building competitive advantage

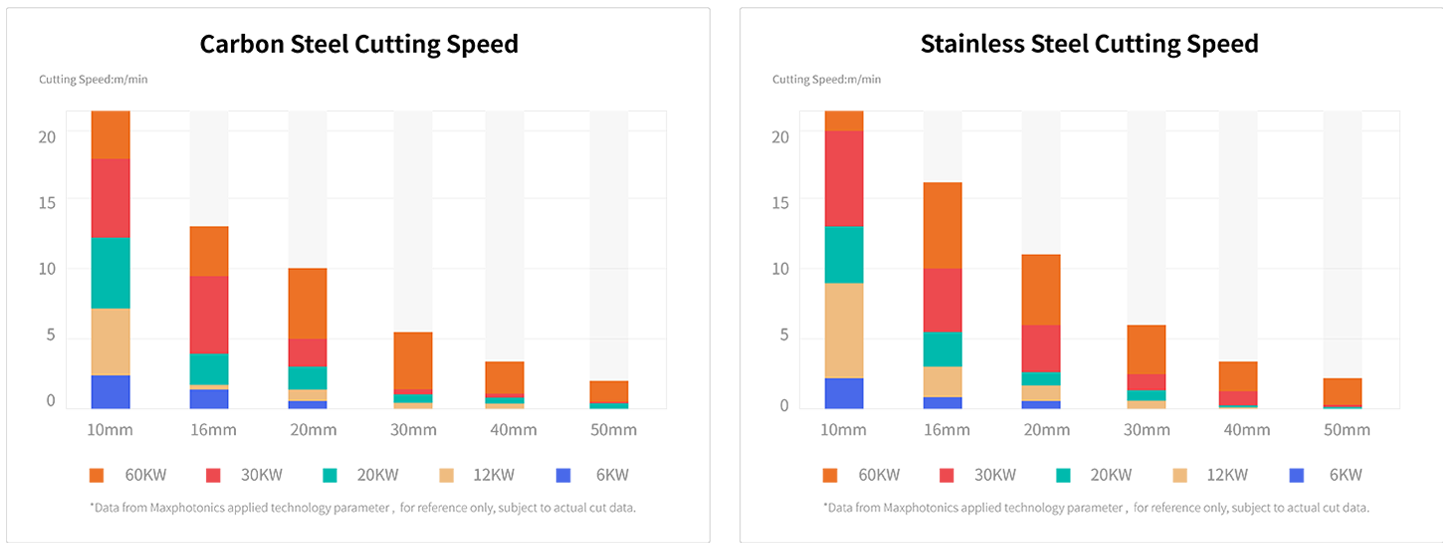

High Power Production Efficiency Comparison Sheet

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

What we can do

The comparison

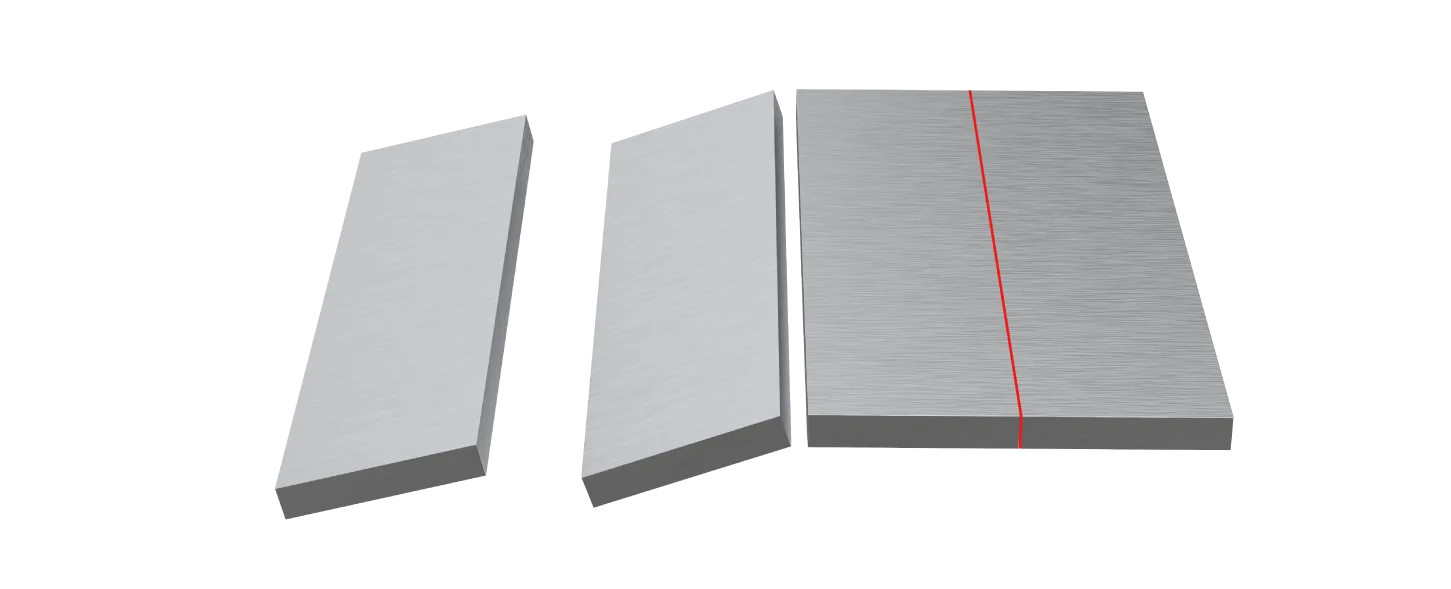

Smooth Micro-joint,improve thermal deformation of parts, save drilling pause time, and prevent warping and collision.

Cutting in batch is easy, and the cutting surface is smooth and clean, production efficiency is higher.

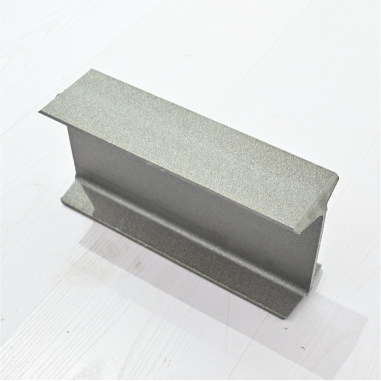

Sample display

Steel outsourcing processing Industry

Steel outsourcing processing Industry

Steel outsourcing processing Industry

building steel structure Industry

Keep reading the Applications

industry cases

New energy industry

It can effectively reduce the processing error and improve the processing precision.

DISCOVER MORE

Elevators manufacturing

It can adapt to any metal pipe within 1.5 tonnes, all kinds of complex shapes and special materials processing needs.

DISCOVER MORE

Shipbuilding

Good cutting section, improve welding quality and increase structural strength

DISCOVER MORE

Machinery industry

It can cutting heavy and long workpieces can be whole perforated cut off

DISCOVER MORE

"Now we have introduced a number of ACME laser tube cutting machines. During , we found that the efficiency is more than 20% higher than that of peers, the failure rate is also low, the operation is simple, and the maintenance is convenient. ACME's technicians trained for two hours, and our workers can operate independently. The after-sales service is even more considerate, the after-sales staff responds quickly, and the problem is solved efficiently. In short, ACME laser tube cutting machine is easy to use and economical."

The price is nice and it’s widely used

READ THE FULL STORY

At present, Dong Fang Hao Yu has purchased two professional laser tube cutting machines LT-9017ES from ACME, they have been serving good operation for customers for two years. These two devices have brought great convenience to the company's production and can meet the various photovoltaic bracket columns cutting needs, which is basically consistent with ACME's promise at the time.”

Brought great convenience

READ THE FULL STORY

"The heavy duty side-mounted machine of ACME, both in terms of performance and processing quality, can stand the test of time!"

improving labor production efficiency

READ THE FULL STORY

"Since purchasing ACME laser machine, our elevator production efficiency has been greatly improved, and the product quality has also been significantly improved. The cutting effect is exquisite and the processing flexibility is high, which has truly solved our problems!"

High-quality processing

READ THE FULL STORY

New Energy Industry

Photovoltaic Bracket Industry

Heavy machinery industry

Elevator manufacturing industry