Reasons to choose Acme A-series

1

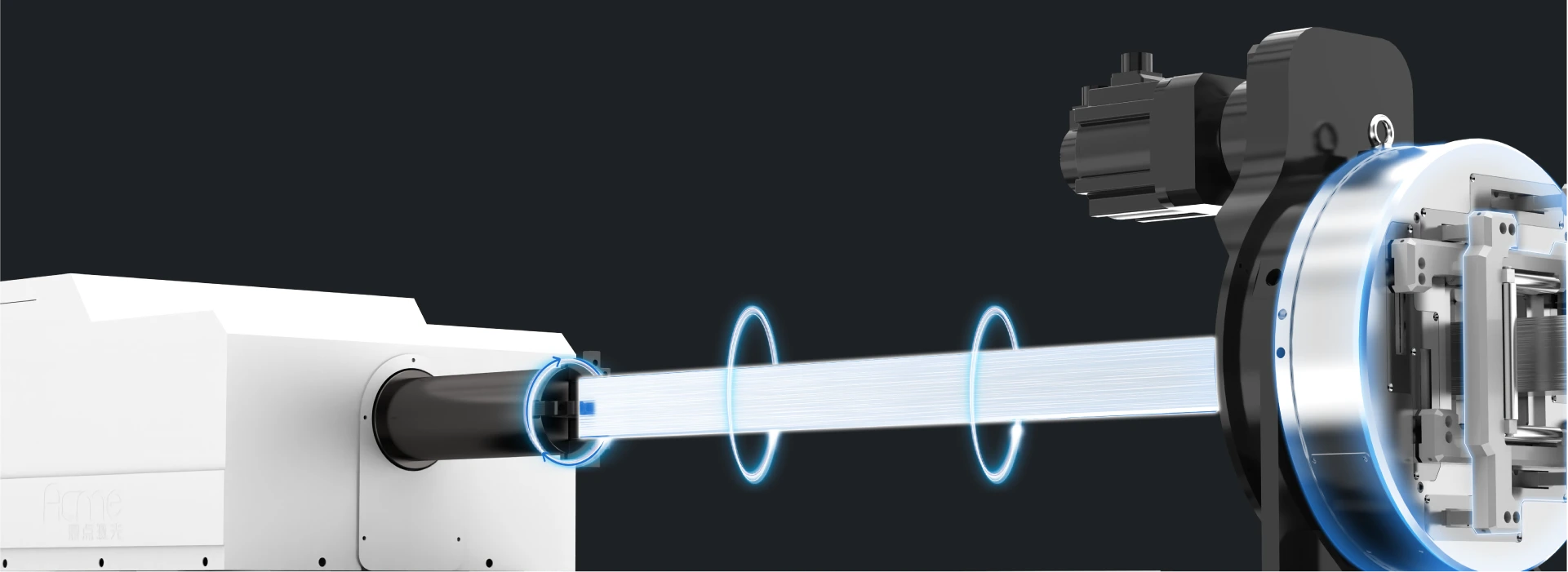

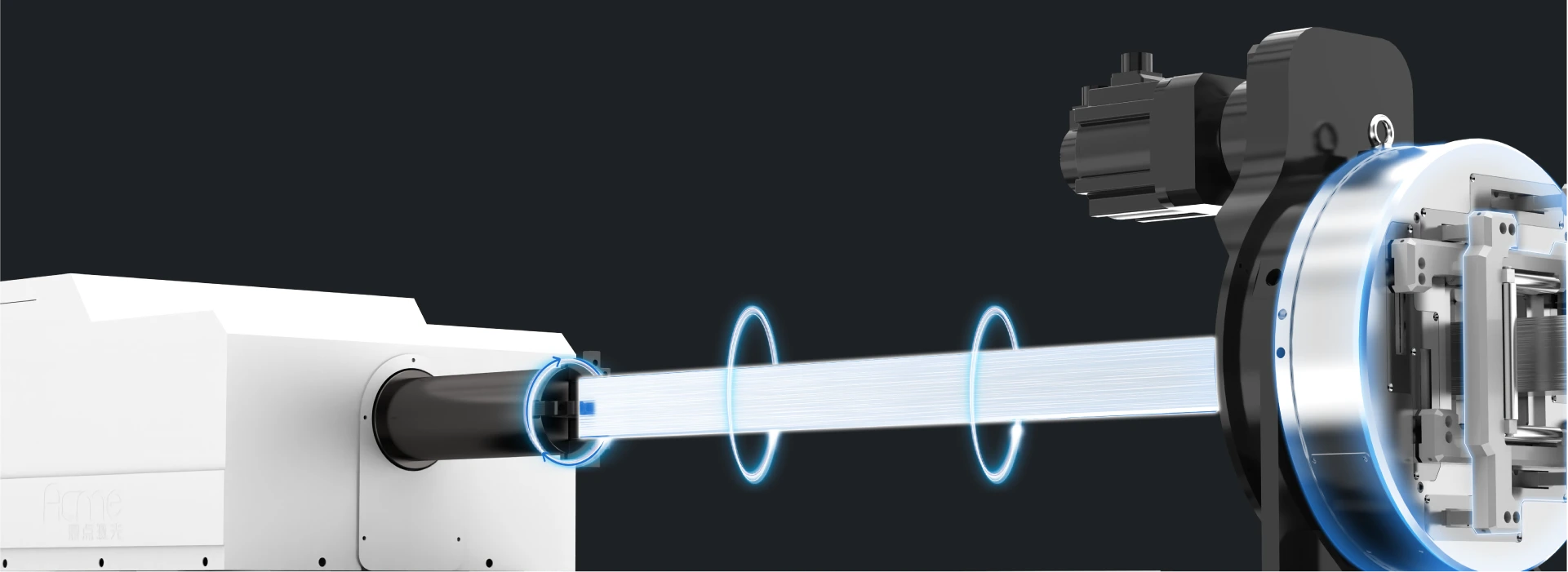

Cutting ability

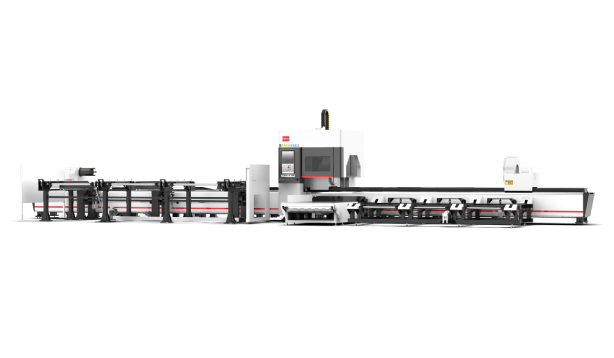

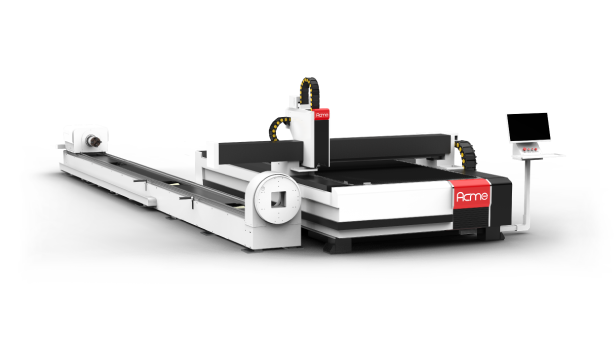

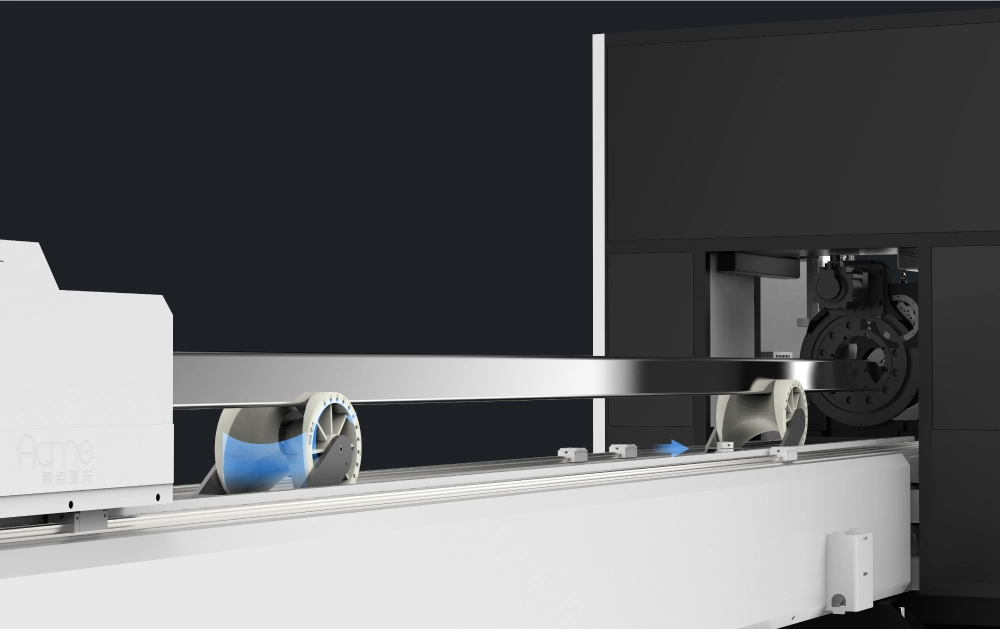

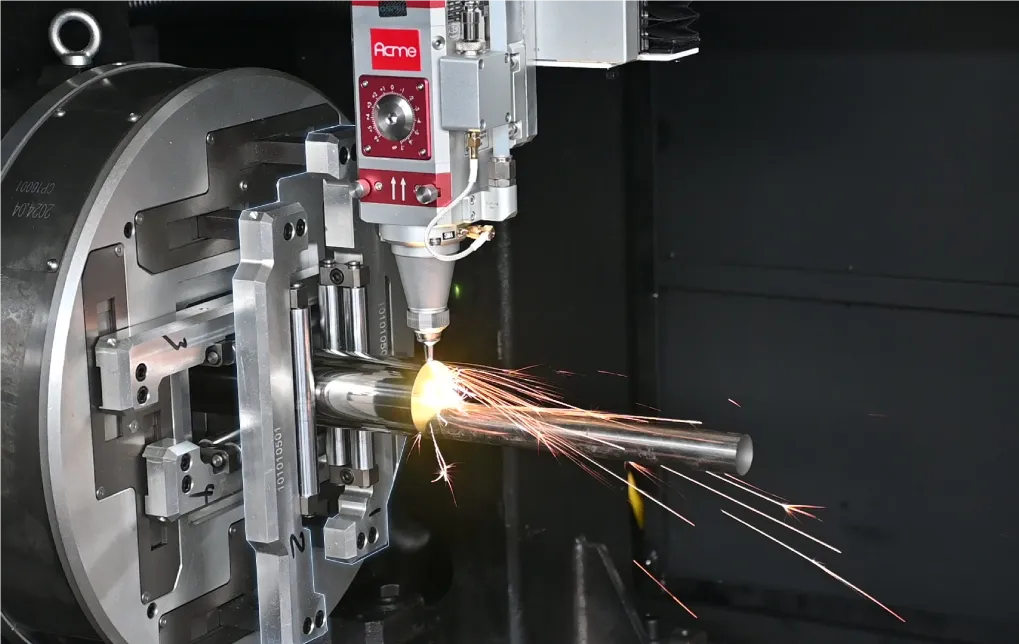

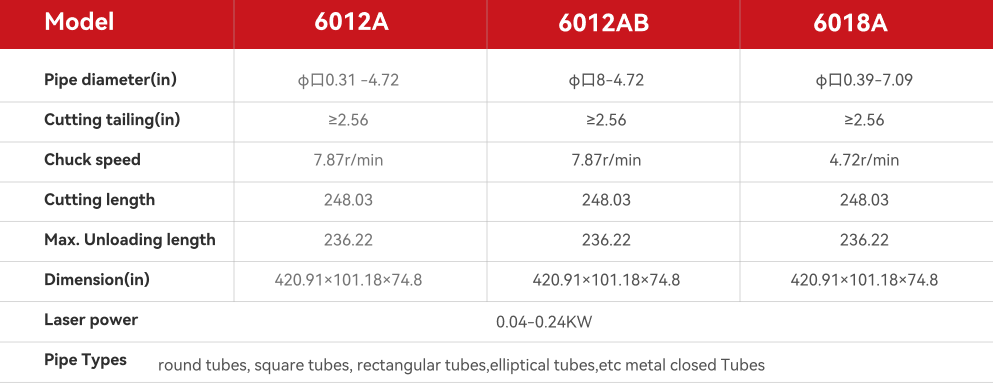

A-Series high speed laser tube cutter, can cut metal closed Tubes, with the length of 6m, the diameter 8-120mm(round tubes, square tubes, rectangular tubes,elliptical tubes,etc metal closed Tubes)

2

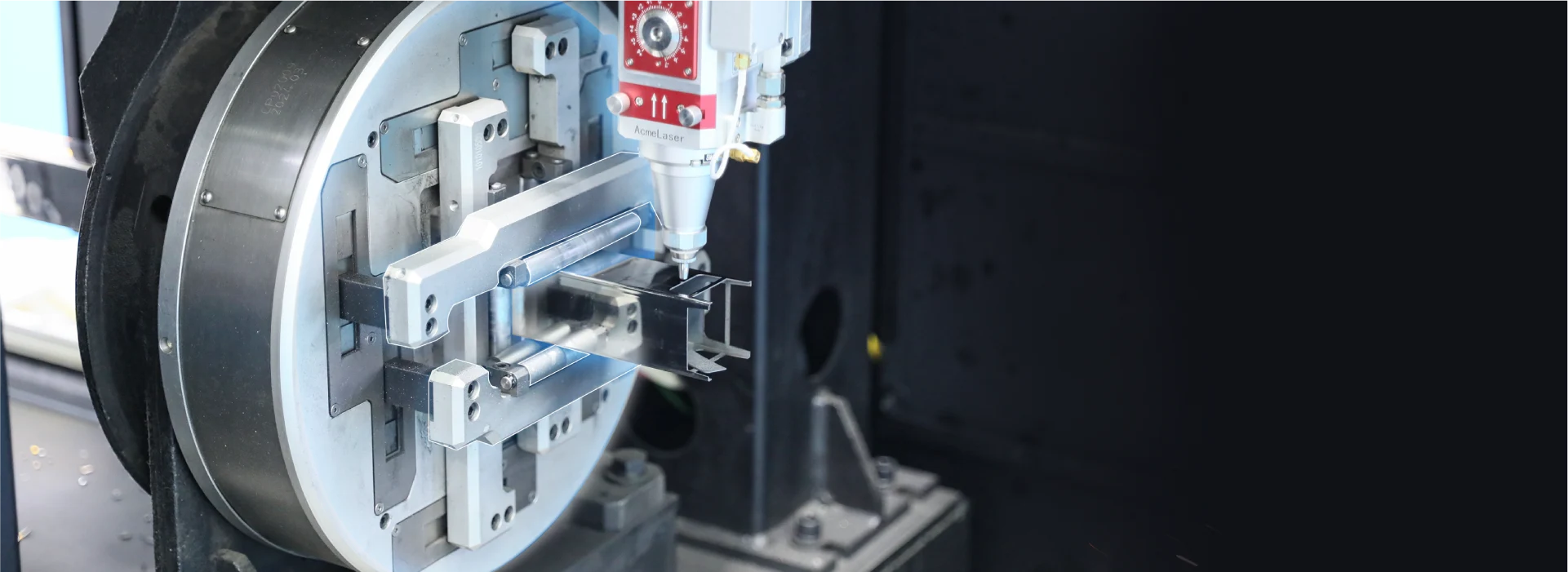

High rotation speed chuck

200r/min, with high cutting efficiency. Each component of ACME's chuck has an ID number, which is convenient for maintenance and care.

3

Bus control system

Adopt EtherCAT bus control system and bus servo driver to ensure the response speed of machine operation and monitor the status of servo motor in real time.

4

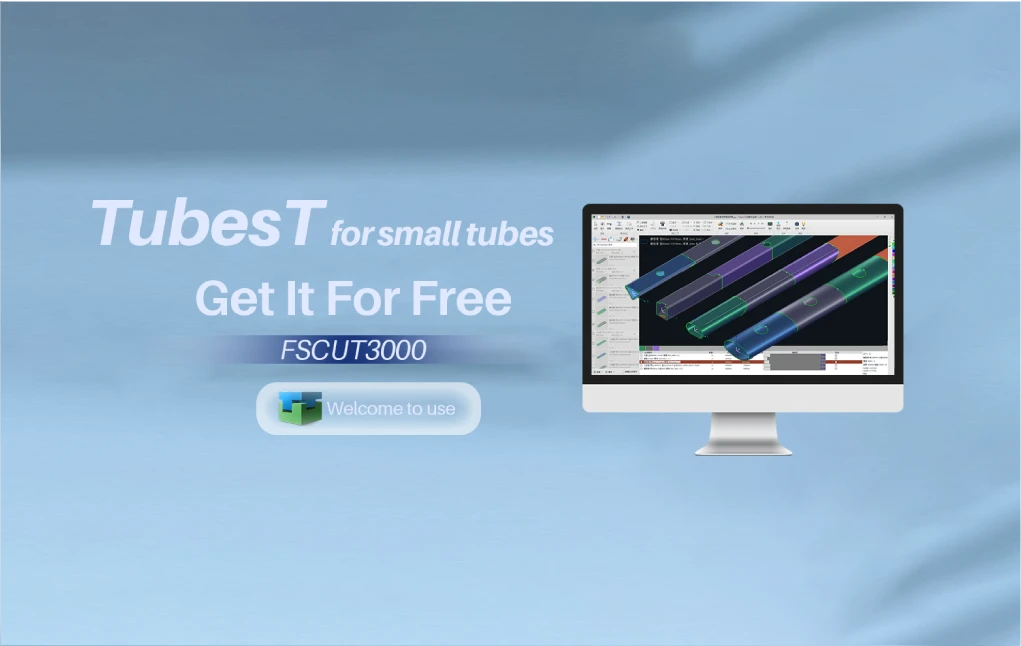

Permanent free

free system upgrade; free nesting software upgrade; free online technical guidance; free help in drawing complex graphics; provide operation video guidance. Reduce downtime waiting time for you.

5

maintenance

2-year maintenance warranty

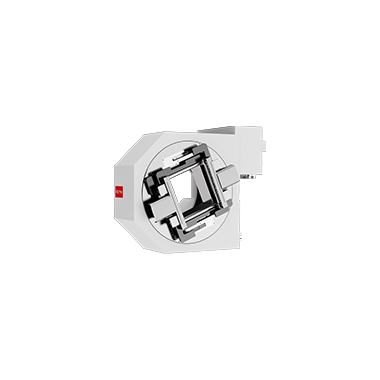

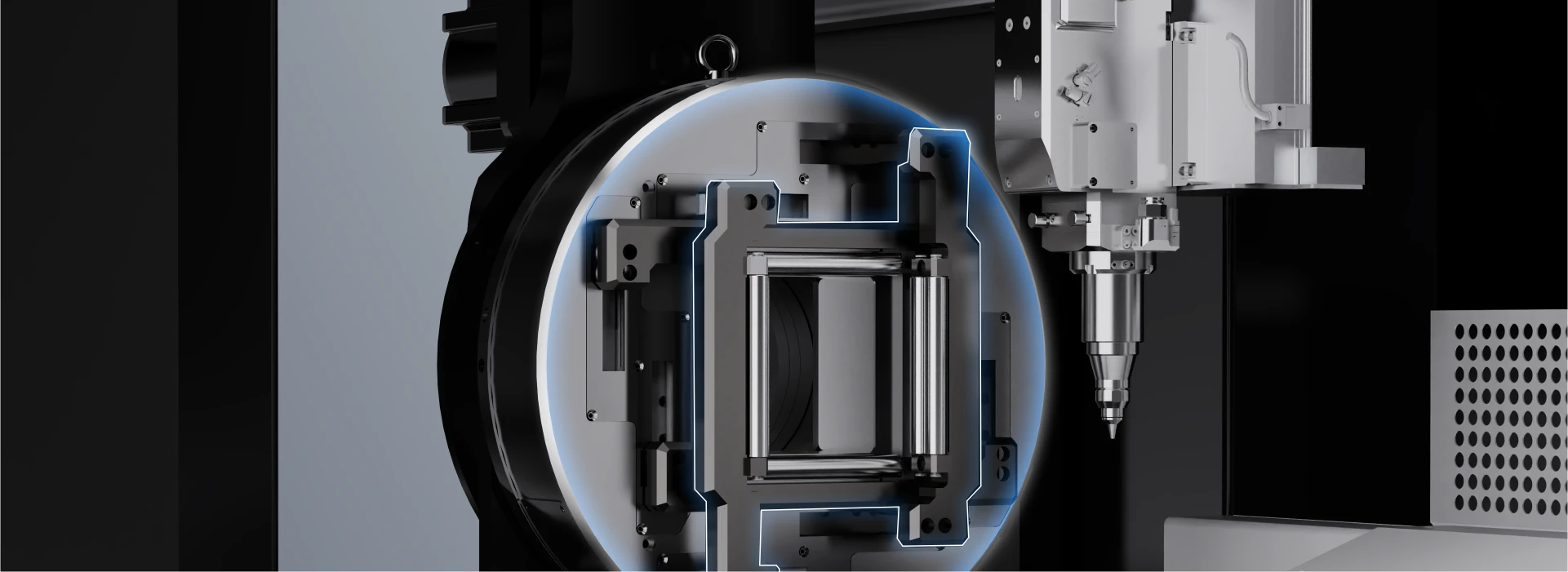

Chucks

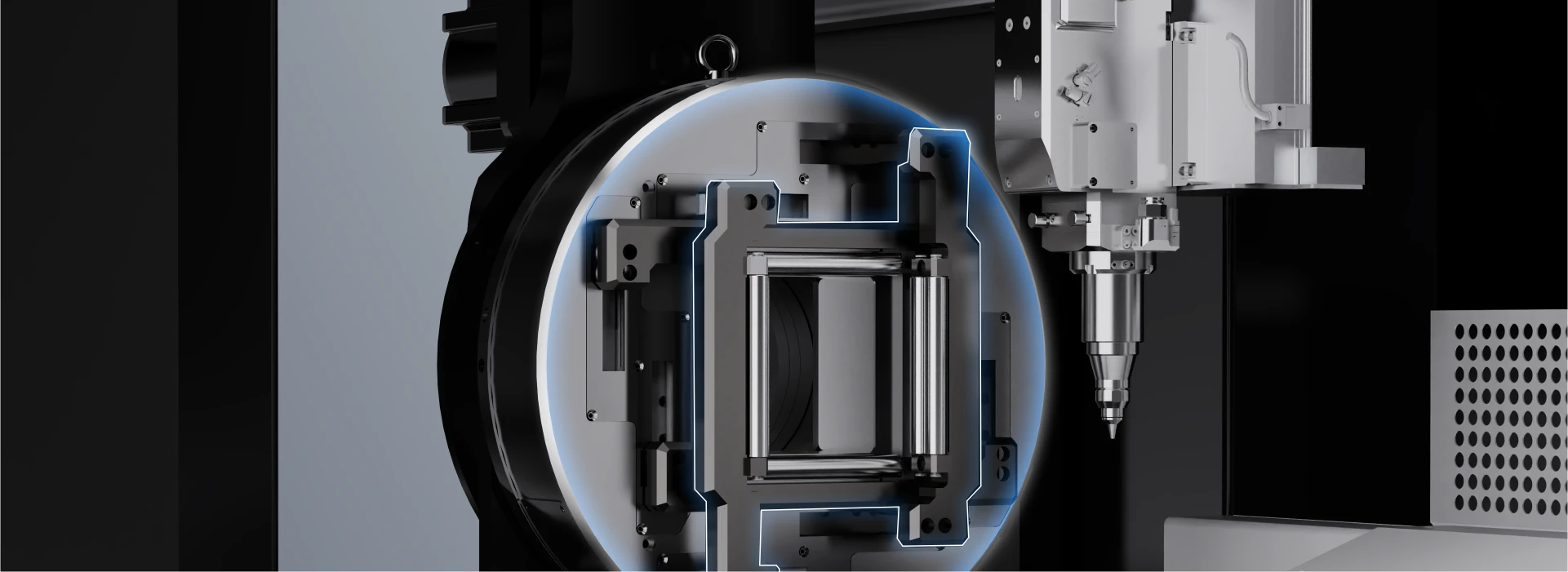

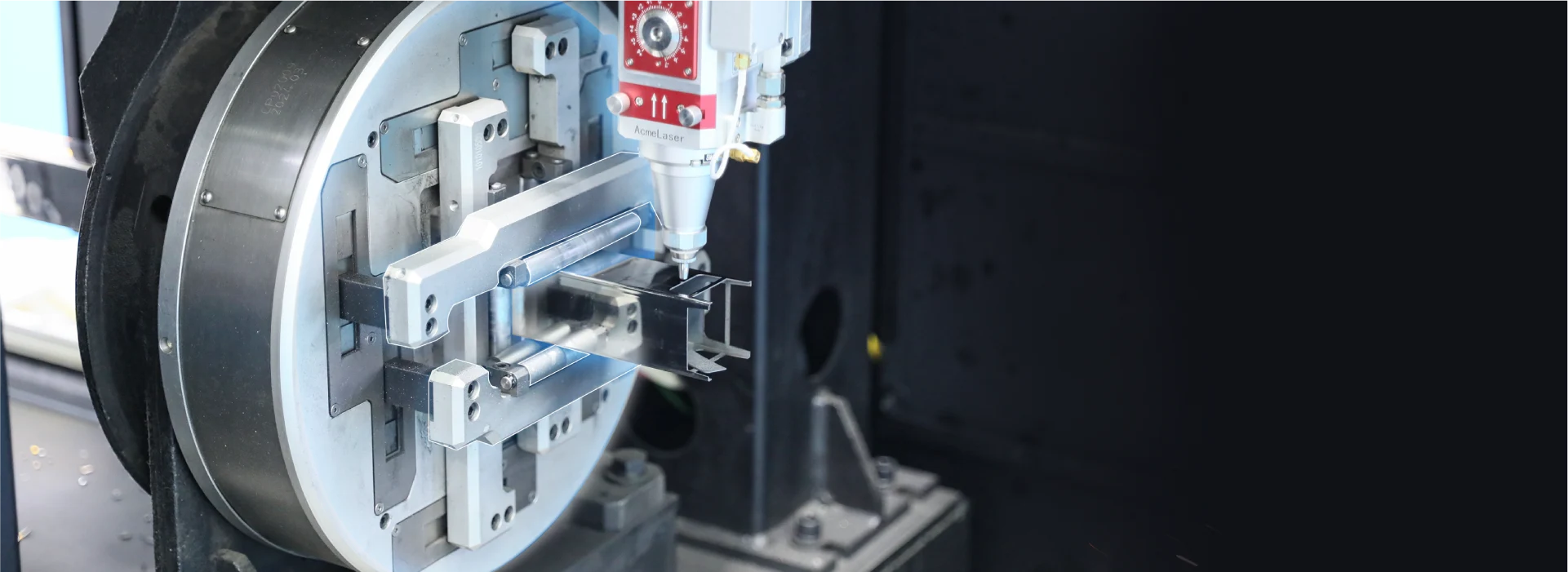

High rotation speed chuck

200r/min, high cutting efficiency

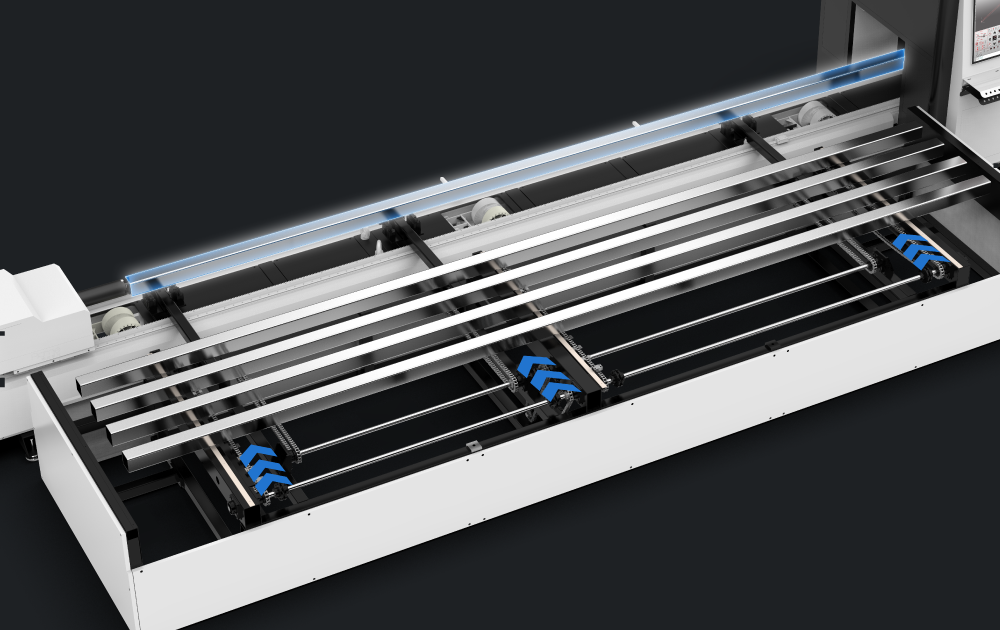

Modular and standard design

The modular design of roller frame group, cylinder group, rack group, etc. has a compact structure, stable performance and easy maintenance.

ACME chuck

Each component of ACME self-developed chuck has ID number for easy maintenance

Innovative technology

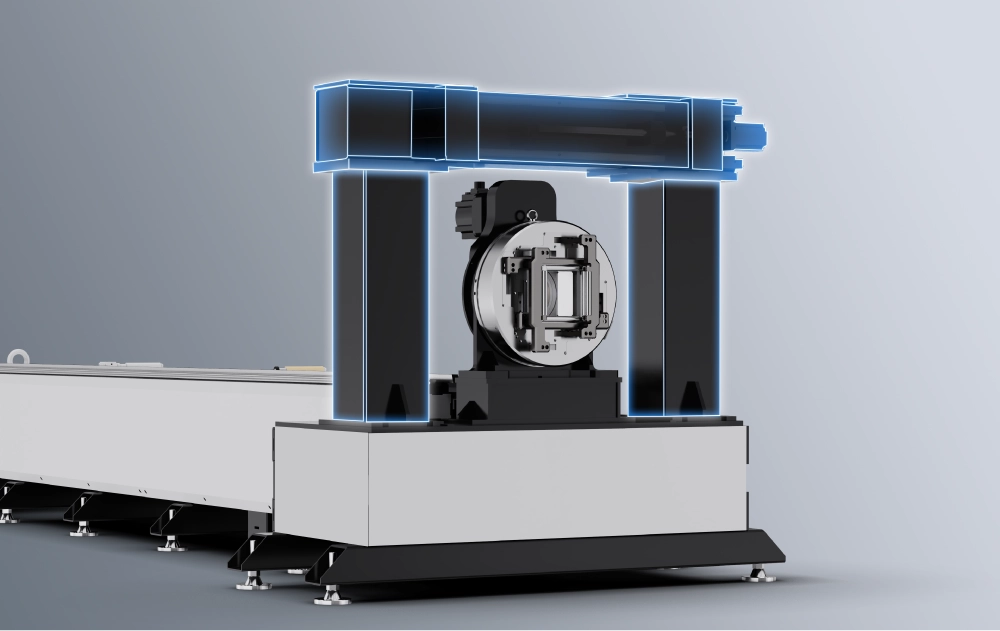

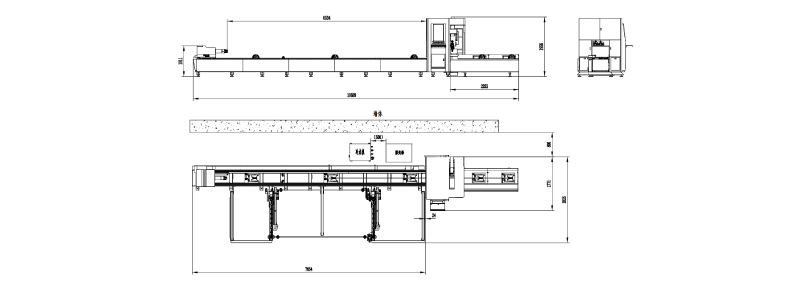

Gantry structure

Variable diameter wheels support

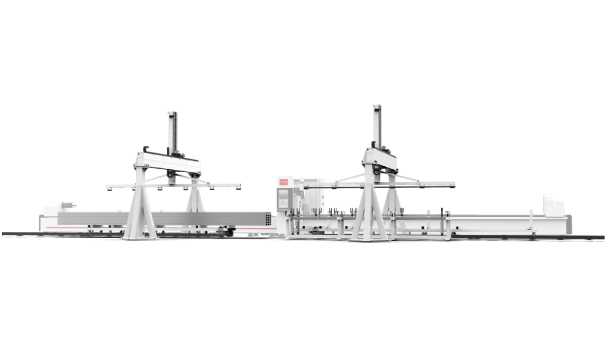

Light-type loader

Gantry structure

Keep the balance of machine, more stable cutting performance and higher cutting precision

Variable diameter wheels support

Equipped with multiple lifting support mechanisms that can rotate and change the Tube diameter, realizing support during the cutting process;

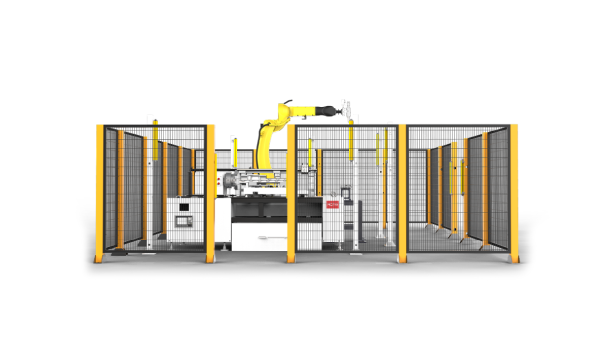

Light-type loader

Optional light loader, compact design, high cost performance; one person can watch over multiple devices, saving labors and improving efficiency.

User-friendly design

System upgrade free; nesting software upgrade free; online technical guidance free; help drawing complex graphics free; provide operation video guidance. Reduce downtime waiting time for you.

Adopt EtherCAT bus control system and bus servo driver to ensure the response speed of machine operation and monitor the status of servo motor in real time.

After installation and commissioning, the equipment can work normally within 2 days, and through within3 days training, the equipment will be ready for production.

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

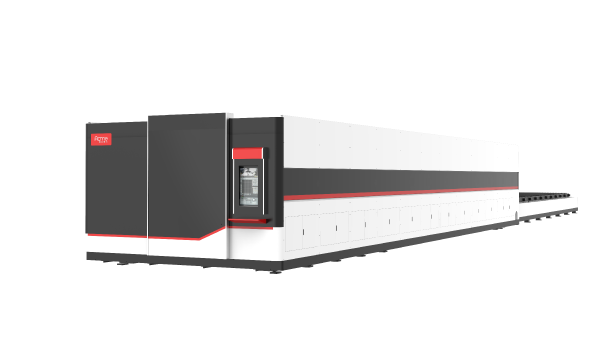

What we can do

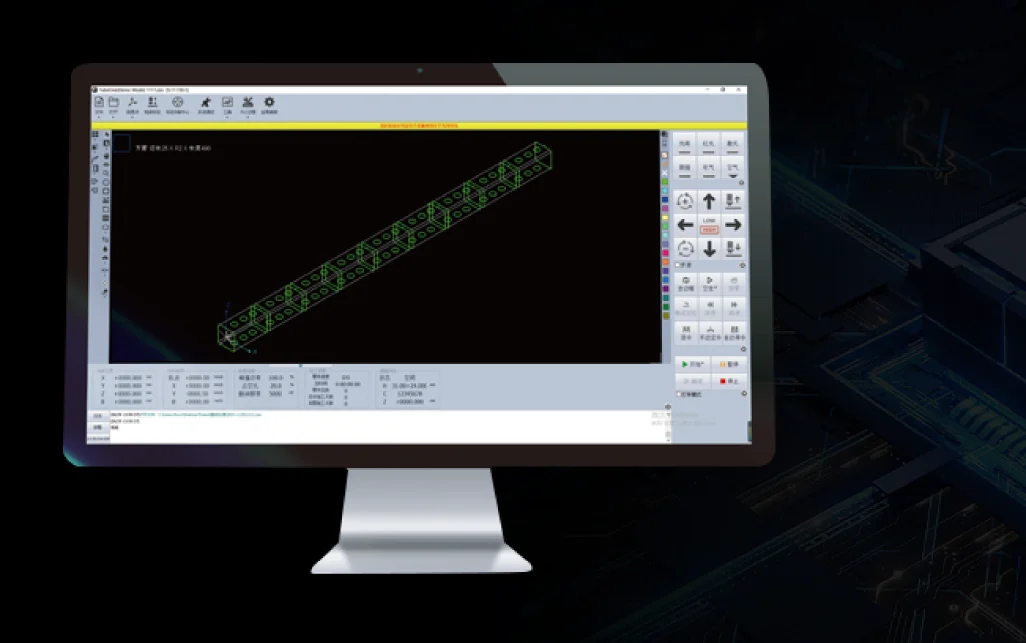

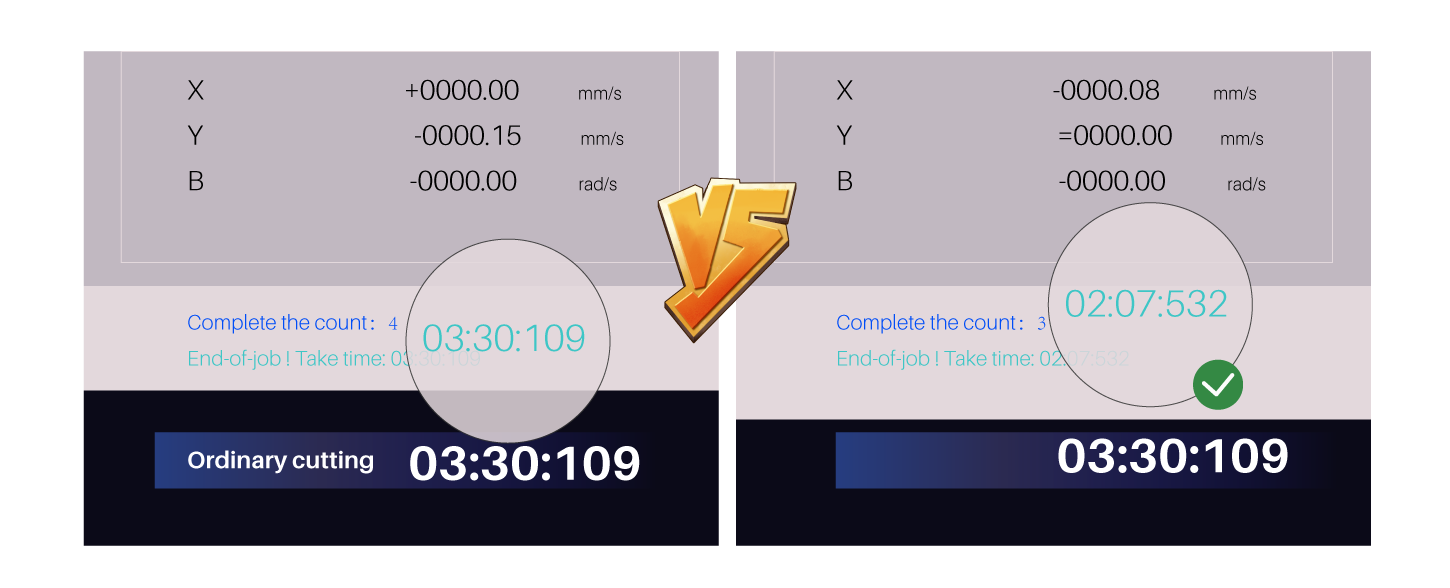

Sorting by surface

Decline the rotations, improve efficiency By comparison, sorting by sides effectively decline the rotations.

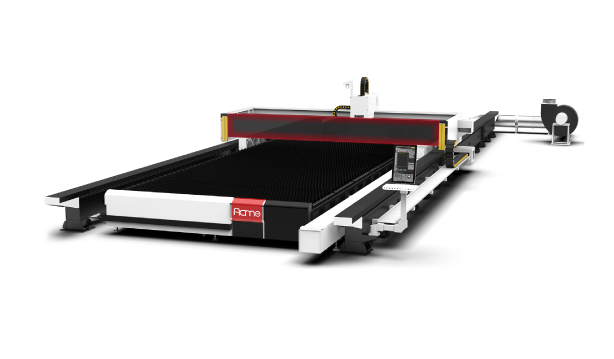

Sample display

campus facilities industry

office furniture industry

Metallurgical manufacturing industry

Building steel structure industry

Windows and doors industry

Keep reading the Applications

industry cases

Science and Education Office

120mm high-speed chuck 200 rpm, fast cutting.

DISCOVER MORE

Guardrail industry

Only needs to input the programming programme according to the demand to cut accurately

DISCOVER MORE

Steel market external processing

No need to dismantle and replace the jaws to improve production efficiency.

DISCOVER MORE

Advertising signs

High dynamic performance, greatly improving production efficiency

DISCOVER MORE

At present, Dong Fang Hao Yu has purchased two professional laser tube cutting machines LT-9017ES from ACME, they have been serving good operation for customers for two years. These two devices have brought great convenience to the company's production and can meet the various photovoltaic bracket columns cutting needs, which is basically consistent with ACME's promise at the time.”

Brought great convenience

READ THE FULL STORY

"Since we purchased these three machines from ACME, we have received more and more orders. In general, the quality, delivery time and output have all improved, and we can meet all customer requirements perfectly. Customers are increasingly trusting us. In addition, ACME has changed our original production model. Currently, we can provide customers with one-stop services, from purchasing raw materials, cutting pipes, welding to galvanizing. With more and more orders, we plan to purchase another one"

Innovative production methods for customers

READ THE FULL STORY

“More than 70% Chinese commercial fitness equipment comes from our vicinity. There are 2,500 fitness equipment factories in our area. Among them, more than 50% use ACME laser machines. ACME has developed together with the fitness equipment industry. They understand our industry needs. A lot of ACME core technology engineers are not available in other bidding manufacturers, which is also an important reason why we chose ACME.”

A large customer group

READ THE FULL STORY

"Now we have two sets machine from ACME. With the recognition of customers and the increasing orders, we plan to purchase one machine again. ACME Laser is my first choice. Because during the six-month using, machine works very well, when having something to ask, ACME team responded and solved promptly. For example, if we need some accessories, they will send from the headquarters immediately. With ACME engineers, we are like friends, communication is very smooth!"

We are like friends with ACME engineers

READ THE FULL STORY

Photovoltaic Bracket Industry

Steel market external processing,

Fitness equipment industry

Outsourcing processing industry