Find your machine

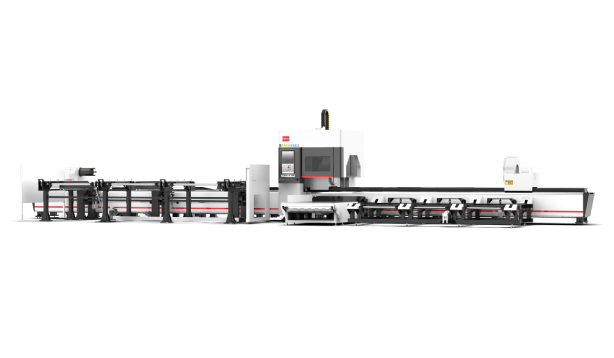

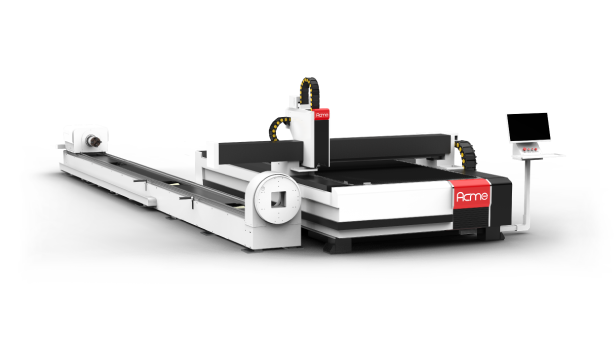

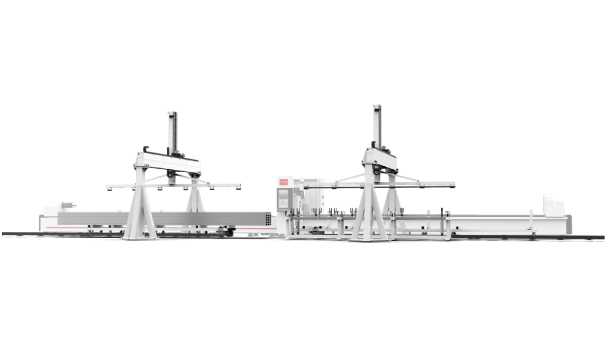

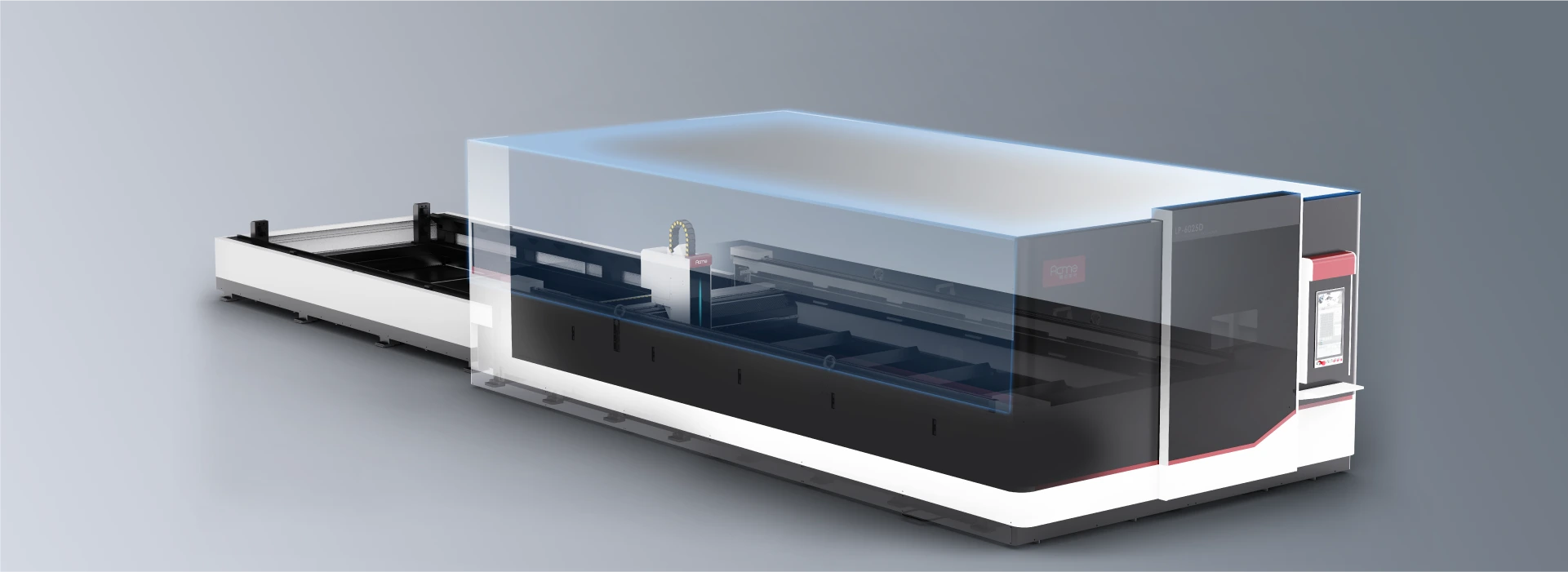

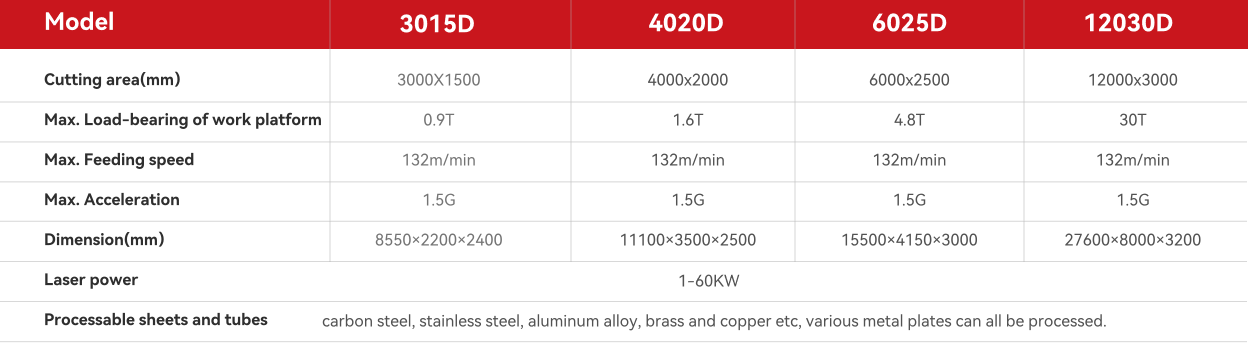

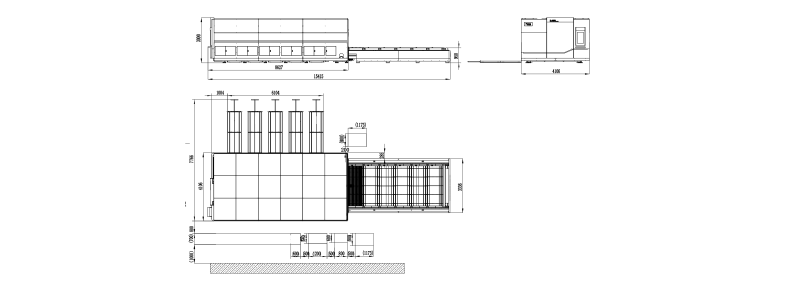

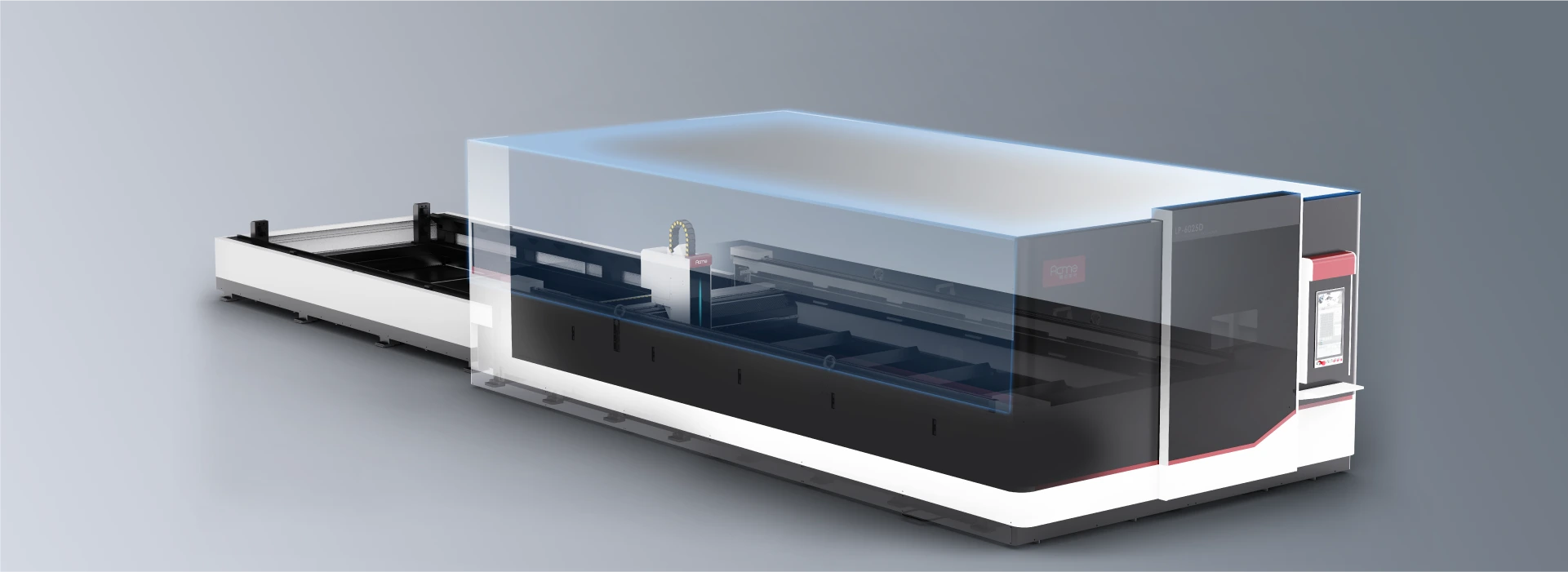

The standard size of the D series machine is 6×2.5m, with the lengths of 3m, 4m, 6m, 8m, 10, 12m, etc. , and the widths of 1.5m, 2m, 2.5m, 3m, 3.5m, etc. (support customization).

please check your equipment information.

3015D

4020D

6025D

10025D

12025D

14025D

Reasons to choose Acme D-series

1

Cutting ability

D series laser sheets cutting machine can cut metal sheets with a length of 3-12m, a width of 1.5-3.5m, and a thickness of less than 100mm;

2

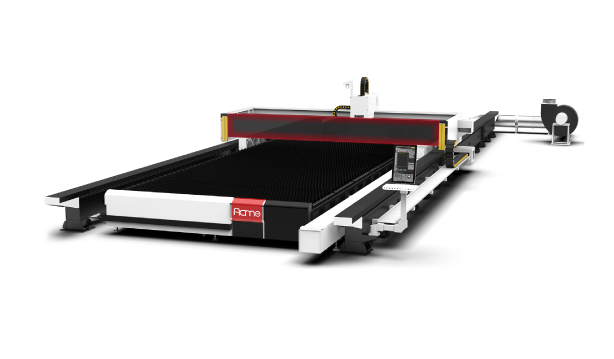

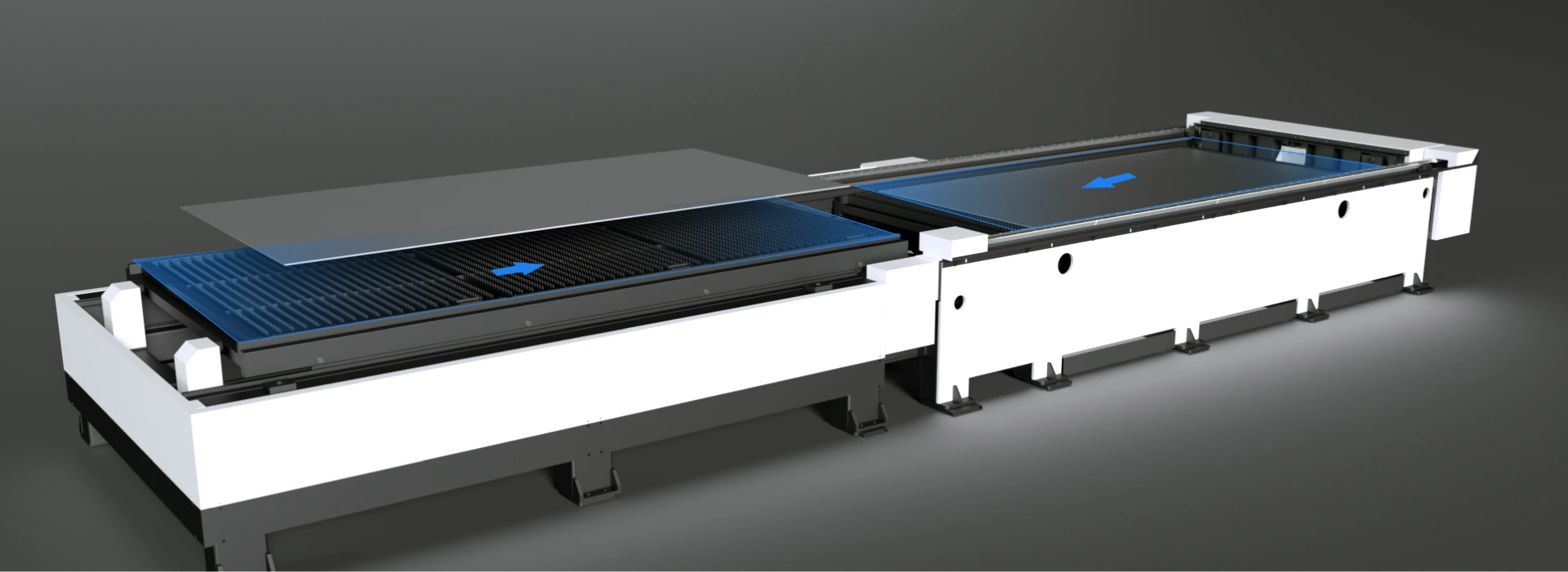

Exchangeable platform design

15S fast exchange, reducing the waiting time for cutting and loading, and effectively improving work efficiency by more than 30%.

3

Superior performance

Dual servo motor high dynamic drive, equipped with extruded aluminum beams, easily handle sheets of various thicknesses;

4

Heavy-duty sheets welded bed

Mortise and tenon structure design, able to withstand greater loads. Laser cutting, large gantry milling machine one-time processing and forming, ensuring years of stable cutting;

5

High-quality production

9 stage piercing, slag-free cutting, smooth micro-joint, intelligent fly-cut, automatic react, cutting path monitor and other complete intelligent processes to ensure efficient and high-quality production;

Performance configuration

Excellent dynamic performance

Dual servo motors are equipped with extruded aluminum beams, with a maximum moving speed of 115m/min and a maximum acceleration of 1.5G, which can efficiently cut sheets of different thicknesses;

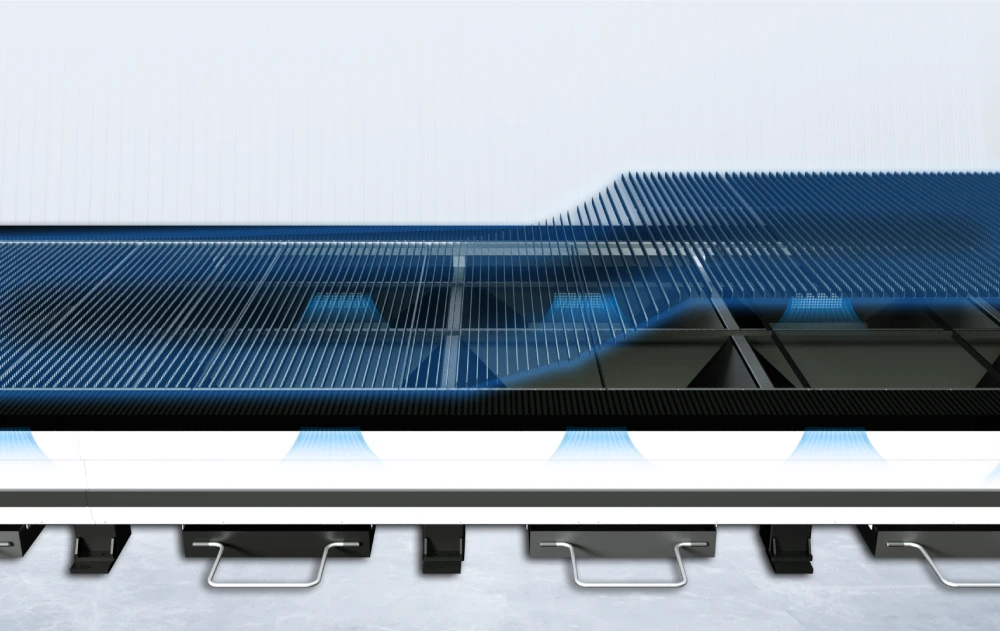

Exchangeable working platform design

15S fast exchange reduces the waiting time for cutting and loading, and effectively improves work efficiency by more than 30%. Designed for large production capacity, it converts high-speed feeding into sheets output;

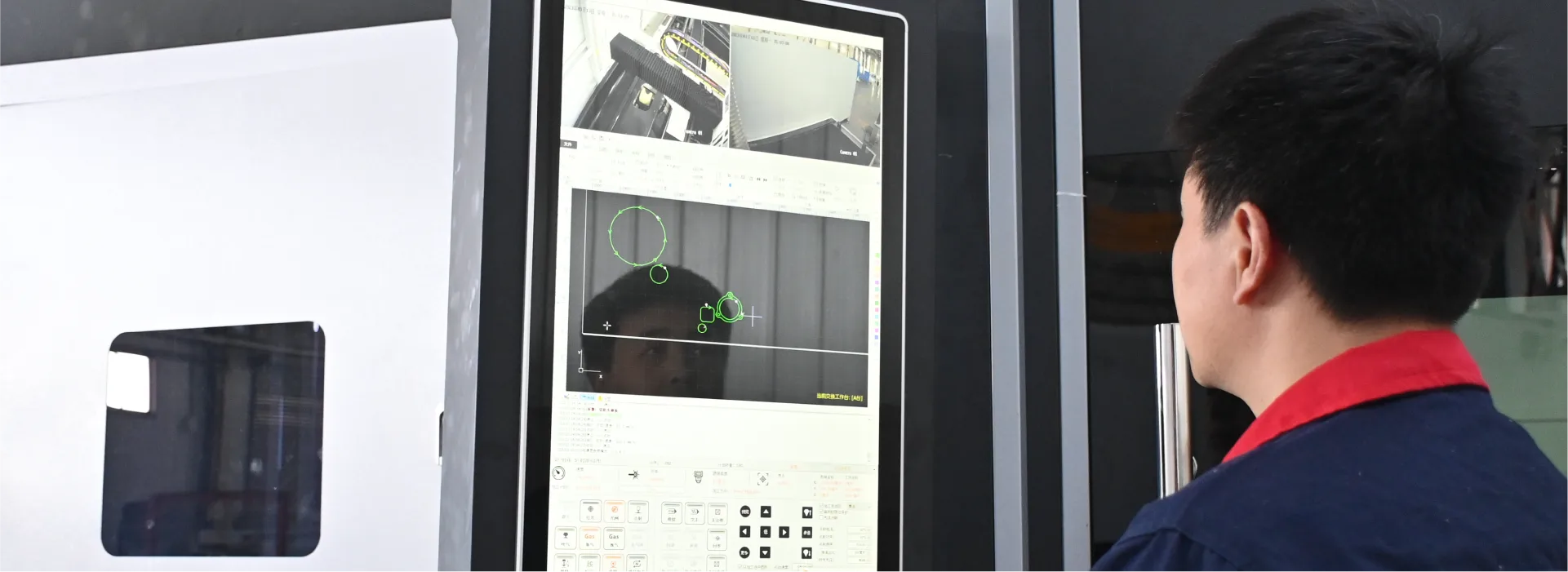

Intelligent processing

Bus system, intelligent and convenient operation, fast response speed, safe production, rich functions, reducing unexpected downtime and extending the life cycle of the machine;

Innovative technology

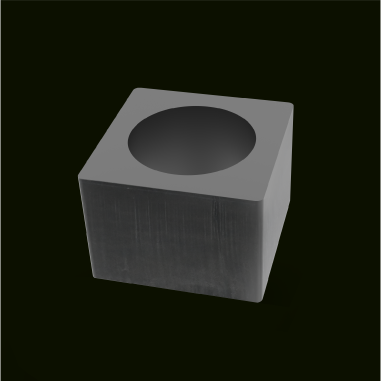

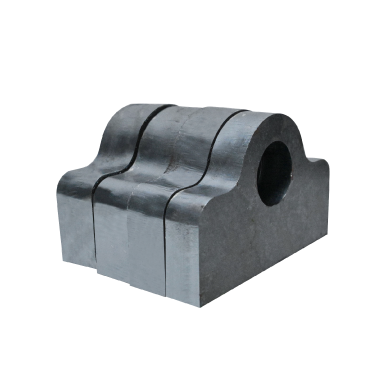

Mortise and tenon structure machine bed

Aerospace grade aluminum beams

Clean cutting

Mortise and tenon structure machine bed

Independent research and development, overall processing, laser cutting, thickened high-quality thick sheets welded, stress annealing and secondary vibration aging treatment, one-time processing and forming by a large gantry milling machine to ensure stable cutting for many years.

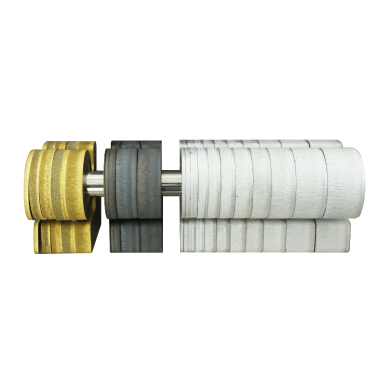

Aerospace grade aluminum beams

Magnesium-aluminum alloy beam, high density, no deformation, stable, fast, lighter and more stable.

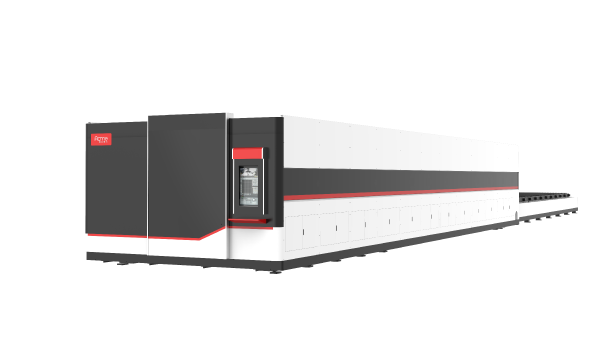

Clean cutting

Good sealing of the machine bed, and the exhaust duct is set on the side, equipped with a high-power fan, which can accurately remove dust in different areas. Improve the precision and quality of cutting. The all-round protective cover design in the cutting area protects the safety and health of the operator.

User-friendly design

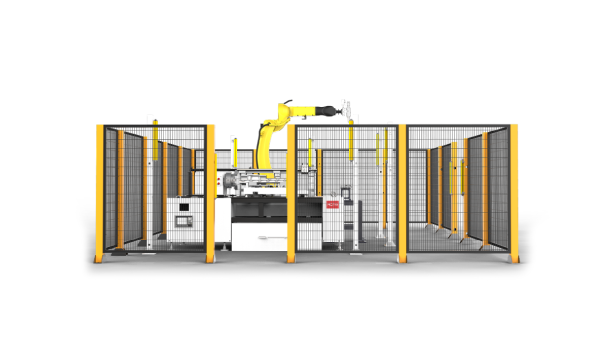

Laser head active avoid collision

Capacitive sensing, fast response speed, reduces the risk of laser head collision caused by work-piece tilting.

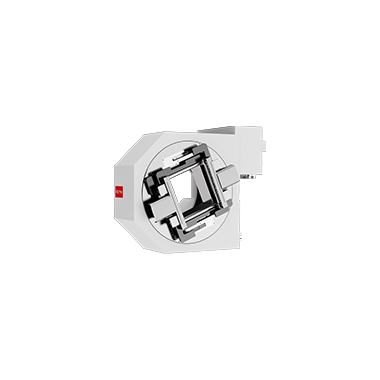

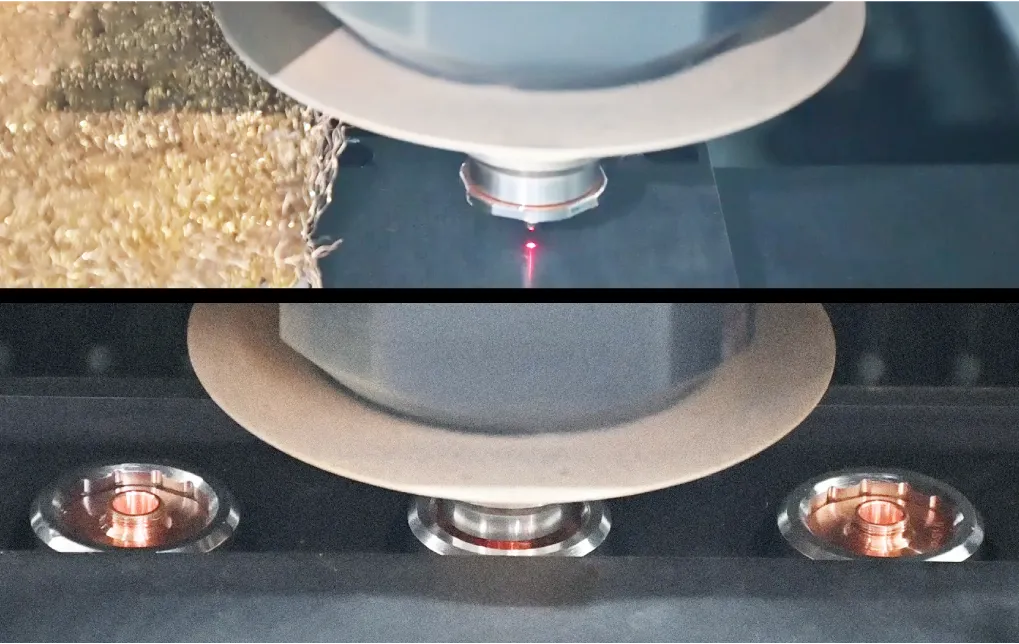

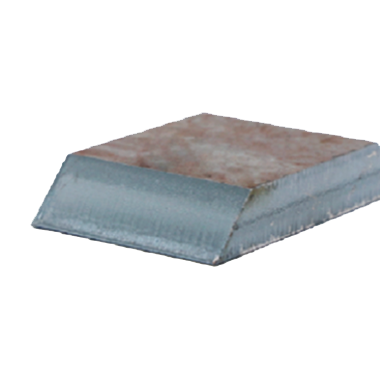

Intelligent gnozzles replacement

Nozzles can be replaced automatically without any human intervention, so that nozzles and lenses can continue to be in a healthy state, reducing the cost of wearing parts and saving operation time.

Large screen display and remote alarm prompts can monitor the production process in real time. No matter where you are, you can keep abreast of production dynamics on your mobile phone to ensure smooth

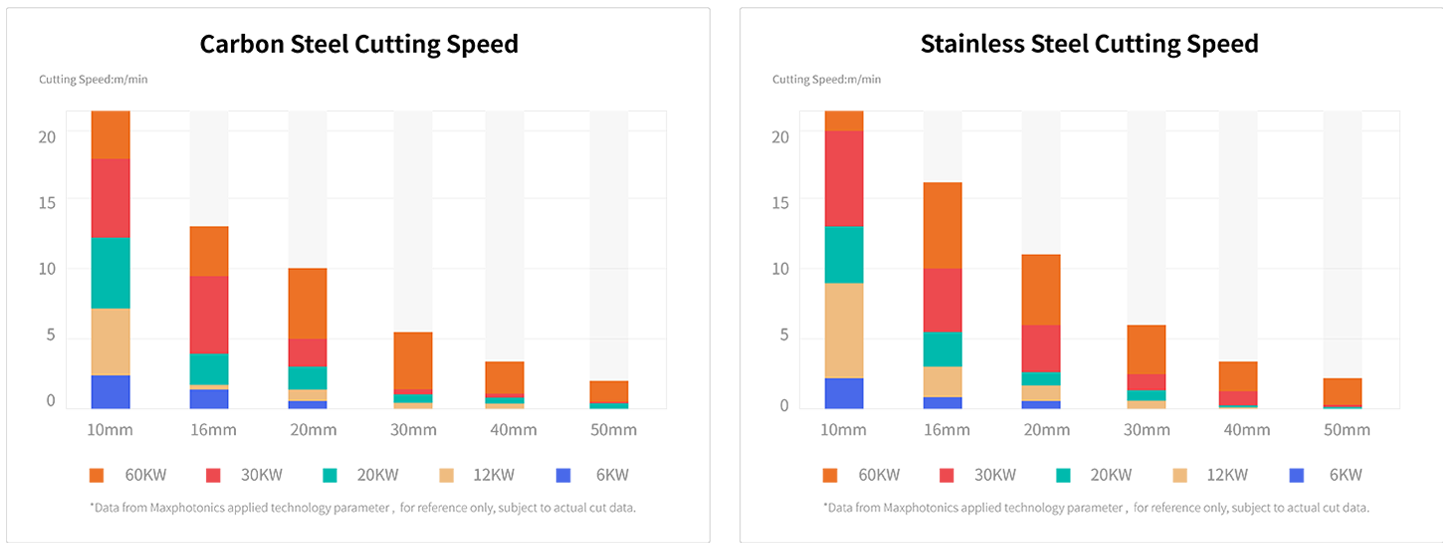

High power production efficiency comparison sheet

12KW, 20KW, 30KW, 40KW, 60KW Cutting Speed Comparison

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

What we can do

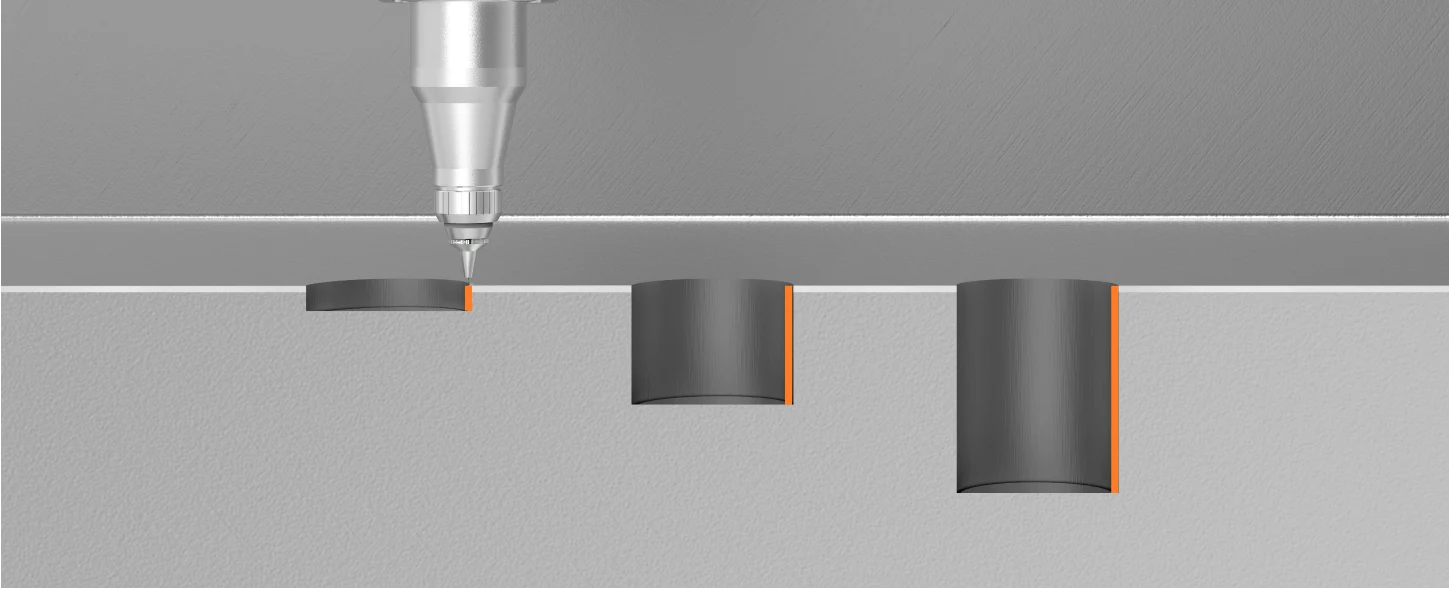

The 9-stage piercing

The 9-stage piercing can significantly enhance the piercing capability of ultra-thick sheets and high-hardness metal materials, effectively avoiding problems in thick sheets cutting, such as explosion, slags, spatter, dross, etc.

Keep reading the Applications

industry cases

New energy industry

It can effectively reduce the processing error and improve the processing precision.

DISCOVER MORE

Elevators manufacturing

It can adapt to any metal pipe within 1.5 tonnes, all kinds of complex shapes and special materials processing needs.

DISCOVER MORE

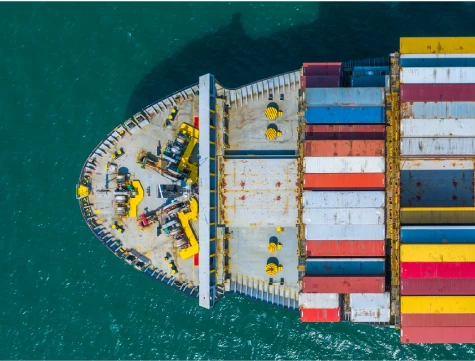

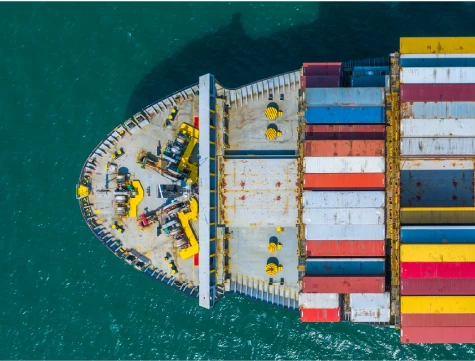

Shipbuilding

Good cutting section, improve welding quality and increase structural strength

DISCOVER MORE

Machinery industry

It can cutting heavy and long workpieces can be whole perforated cut off

DISCOVER MORE

"Now we have introduced a number of ACME laser tube cutting machines. During , we found that the efficiency is more than 20% higher than that of peers, the failure rate is also low, the operation is simple, and the maintenance is convenient. ACME's technicians trained for two hours, and our workers can operate independently. The after-sales service is even more considerate, the after-sales staff responds quickly, and the problem is solved efficiently. In short, ACME laser tube cutting machine is easy to use and economical."

The price is nice and it’s widely used

READ THE FULL STORY

"The heavy duty side-mounted machine of ACME, both in terms of performance and processing quality, can stand the test of time!"

improving labor production efficiency

READ THE FULL STORY

"Since purchasing ACME laser machine, our elevator production efficiency has been greatly improved, and the product quality has also been significantly improved. The cutting effect is exquisite and the processing flexibility is high, which has truly solved our problems!"

High-quality processing

READ THE FULL STORY

“ Since we used ACME Laser’s machine, the tubes cutting accuracy and efficiency in ship manufacturing have been significantly improved, solving many previous problems and making our production smoother and more efficient.”

Enhancing the quality of parts

READ THE FULL STORY

New Energy Industry

Heavy machinery industry

Elevator manufacturing industry

Shipbuilding industry