ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

Cutting thick materials faster reduces production time and increases throughput, and this increased speed translates into higher productivity and profitability.

Cutting thick materials faster reduces production time and increases throughput, and this increased speed translates into higher productivity and profitability.

Laser cut metal parts have smooth surfaces and edges with no burr scratches, reducing friction, wear and corrosion and providing smooth, high quality workpieces.

Laser cut metal parts have smooth surfaces and edges with no burr scratches, reducing friction, wear and corrosion and providing smooth, high quality workpieces.

Efficiently cuts a wide range of materials and thicknesses, serving more scenarios and taking on more complex projects. It helps to remain competitive strength in the industry, increasing profits.

Efficiently cuts a wide range of materials and thicknesses, serving more scenarios and taking on more complex projects. It helps to remain competitive strength in the industry, increasing profits.

High-power lasers have high photoelectric conversion rates, which reduce electricity costs; Using air cutting, redusing the oxygen and ammonia consumption, which reduces gas costs; and the avoidance of manual intervention and downtime improves production capacity and revenue.

High-power lasers have high photoelectric conversion rates, which reduce electricity costs; Using air cutting, redusing the oxygen and ammonia consumption, which reduces gas costs; and the avoidance of manual intervention and downtime improves production capacity and revenue.

High-power equipment improves productivity, increasing production and profits. It also improves product quality, customer satisfaction and market competitiveness. Although the initial investment is high, they have a long service life and a high long-term return.

High-power equipment improves productivity, increasing production and profits. It also improves product quality, customer satisfaction and market competitiveness. Although the initial investment is high, they have a long service life and a high long-term return.

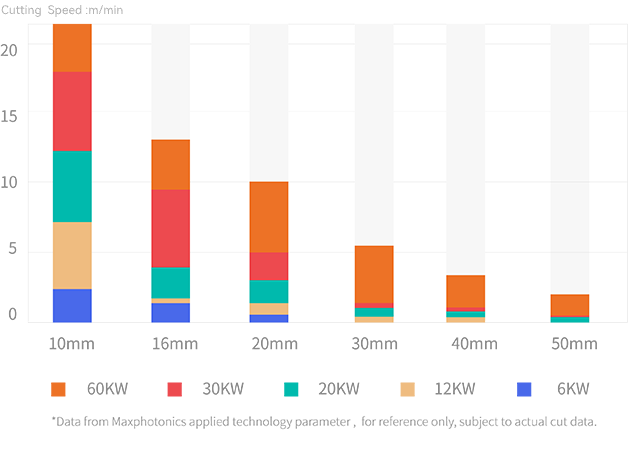

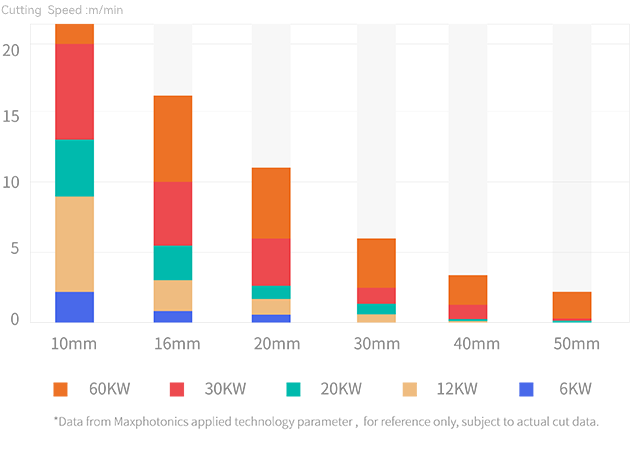

12KW, 20KW, 30KW, 40KW, 60KW Cutting Speed Comparison

Carbon steel Cutting Speed

Stainless Steel Cutting Speed

Innovative cutting technology guarantees perfect processing quality

Complex cutting techniques ensure excellent machining quality

Heavy Duty Tube Laser cutting Machine

Diameter

850/650/550/360

3D

Power

6-30KW

Zero Tailings

Two-chuck Side-hanging Laser Tube Cutting Machine

Diameter

280/260/230

3D

Power

1-20KW

Fully Automatic Laser Tube Cutting Machine

Diameter

180/120

3D

Power

1-6KW

High Speed Laser Tube Cutting Machine

Diameter

120/180

2D

Power

1-6KW