Reasons to choose Acme LHM-series

1

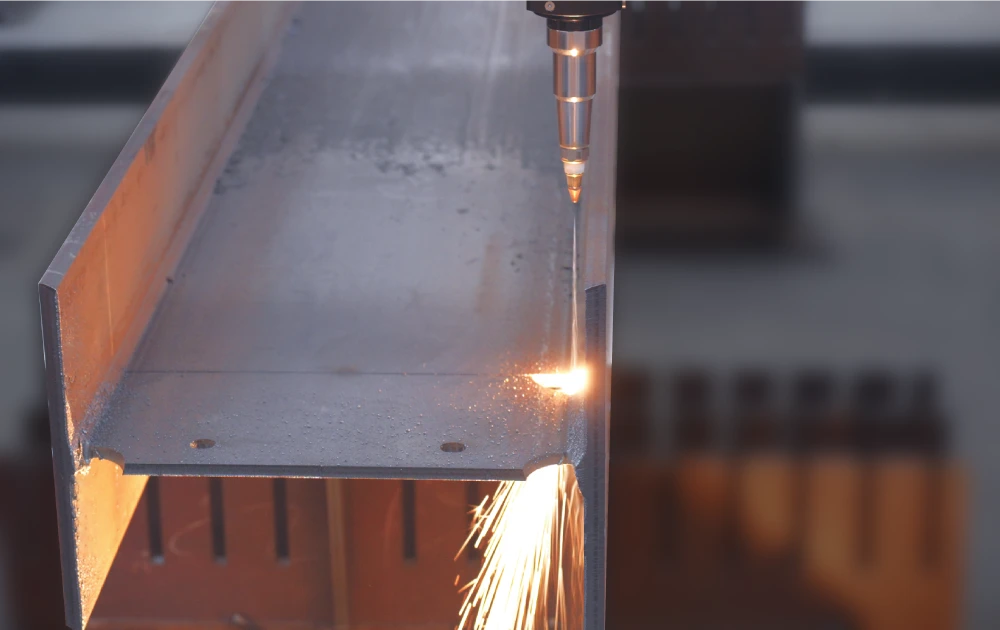

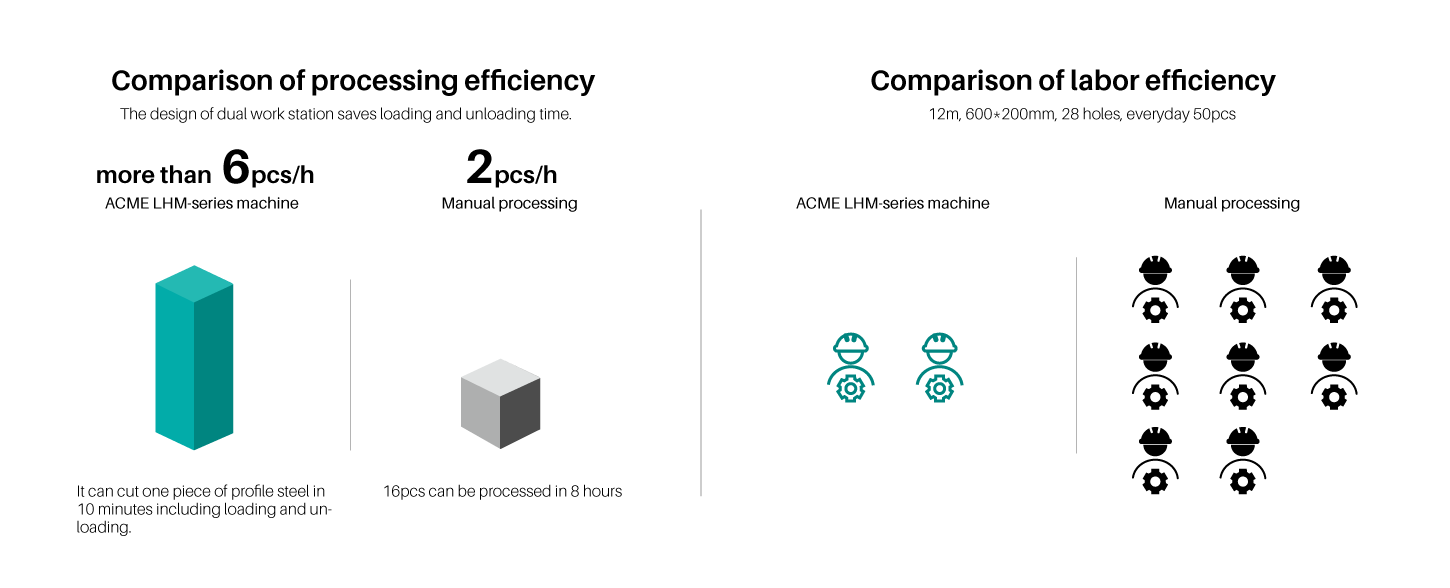

Cutting ability

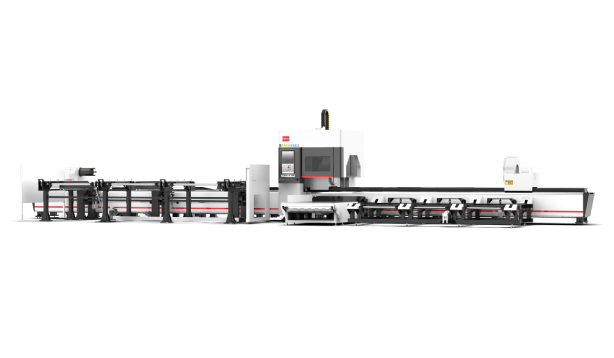

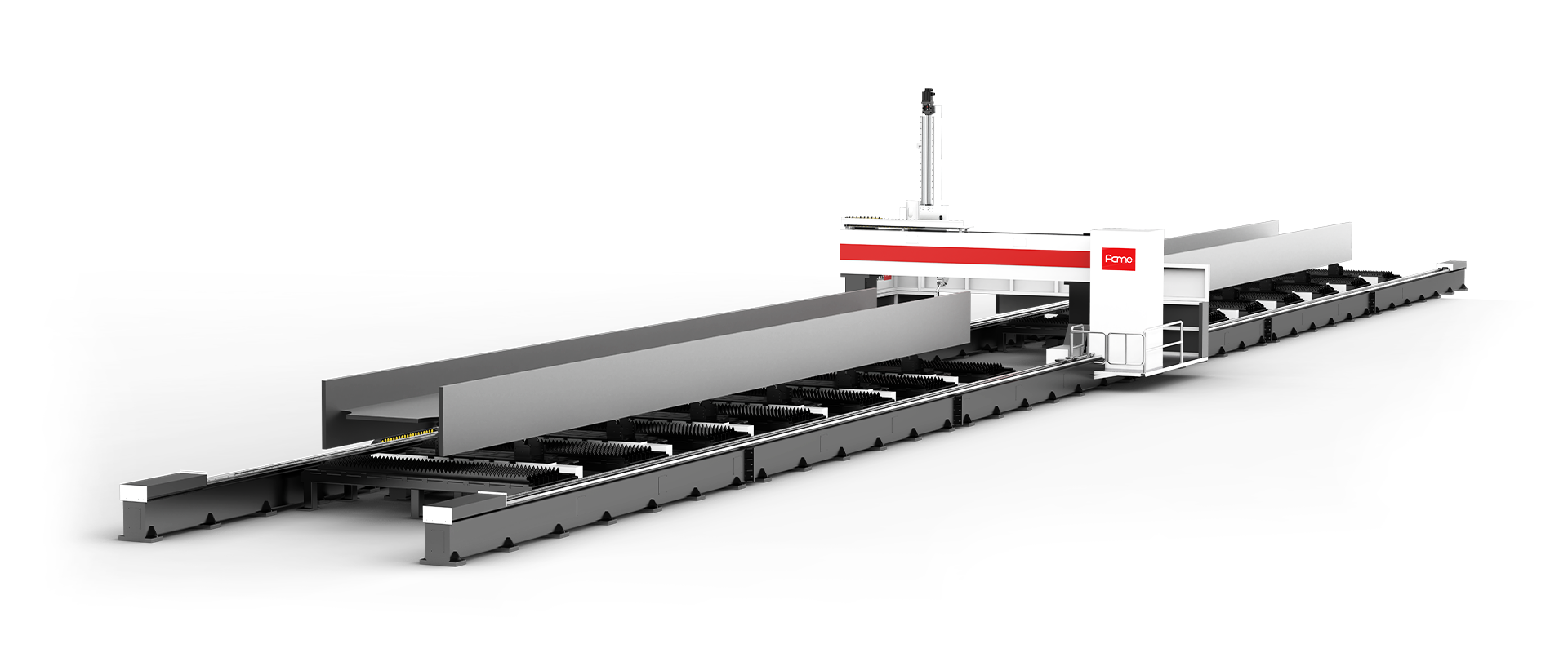

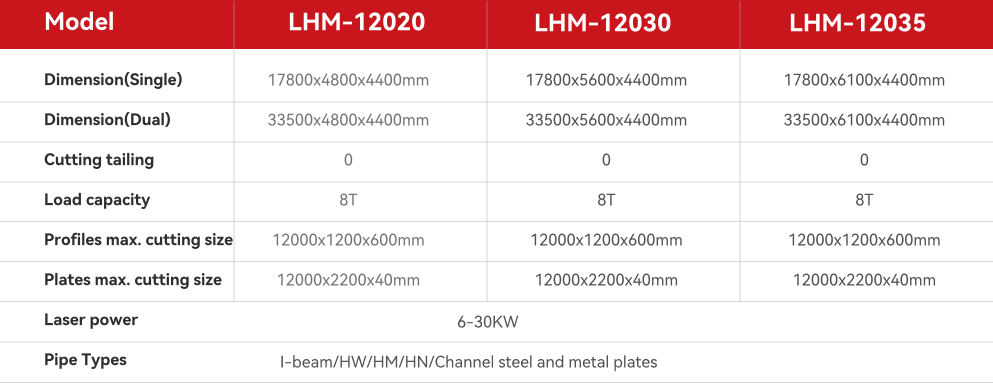

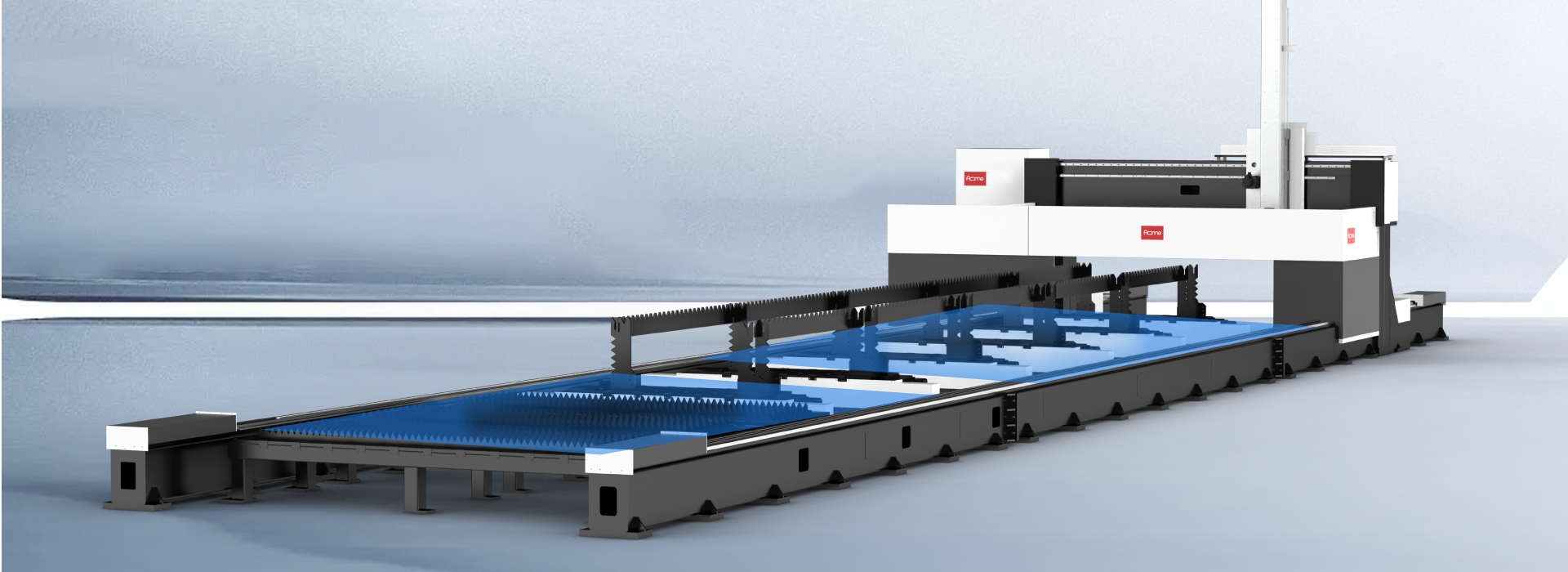

T-Series two-chuck side hanging laser Tube cutting machine, can cut any metal Tubes, with the length of 6-15m, the diameter 8-640mm, and the weight of 2.6 tons or less.

2

Profiles and plates cutting

hole-cutting, engraving, and marking can be done in one machine.Powerful cutting ability,one-time processing and shaping;

3

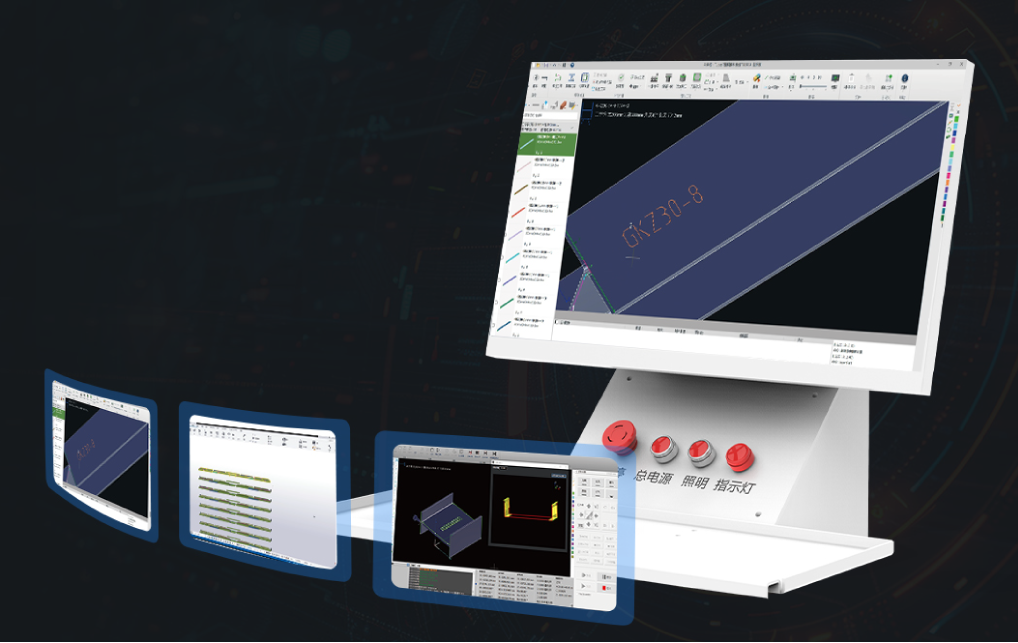

Connect with Tekla

offering efficient drawing and nesting,Support various bevel cutting processes;

4

Zero tailing cutting

Special structure design supports zero tailing cutting;

5

Supports customization

such as dual work station, one machine with multiple functions.

Autonomous components

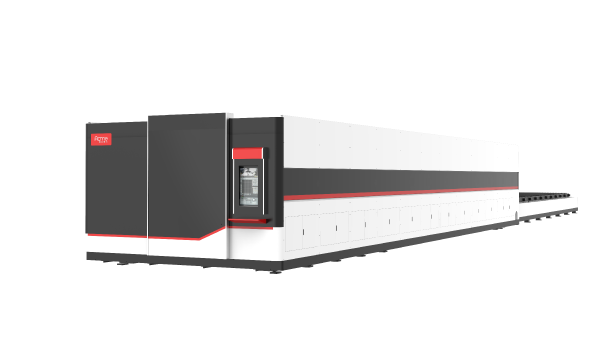

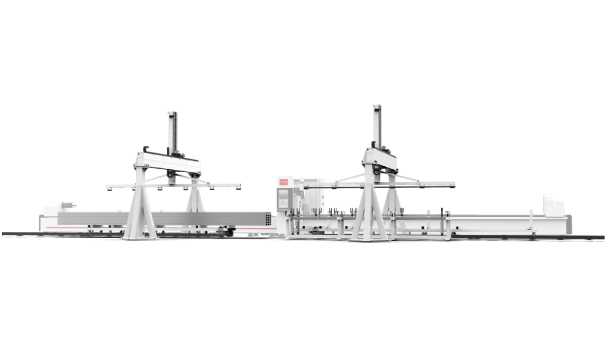

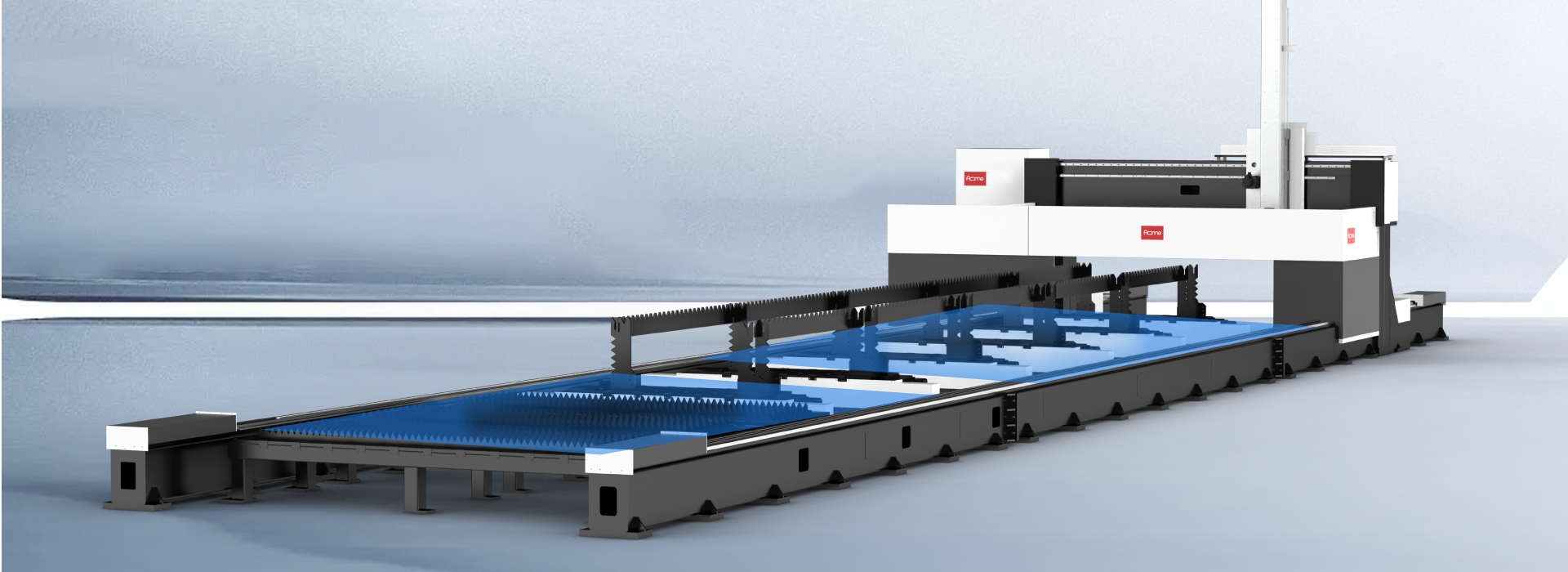

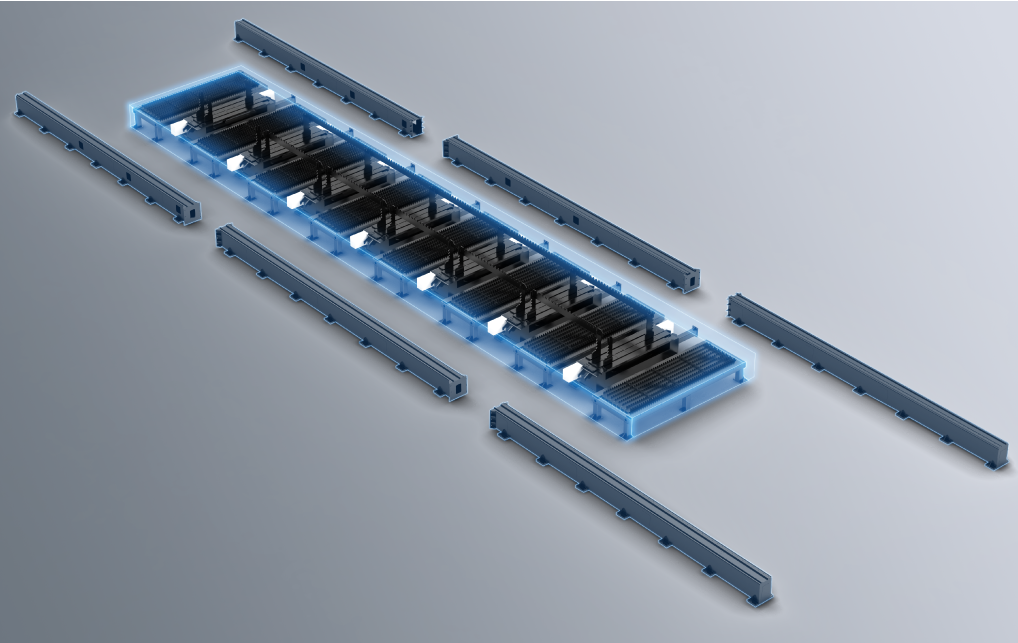

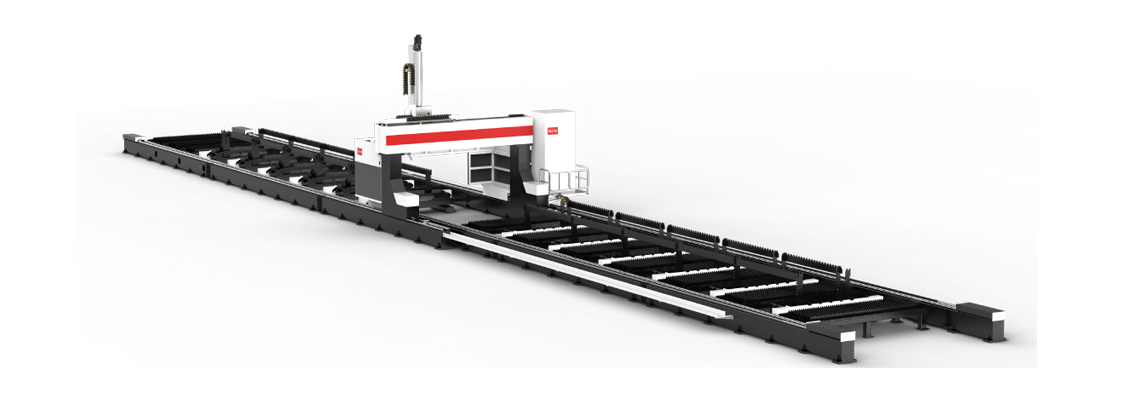

Machine bed structure

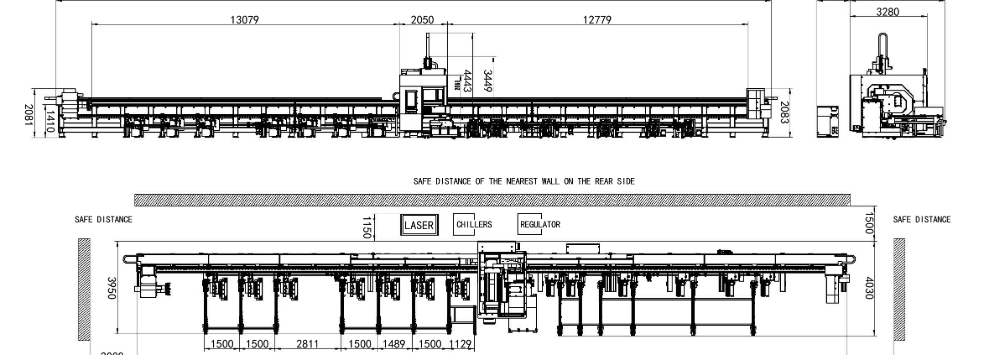

The bed has a ground rail structure. The segmented splicing structure is used to facilitate large-format customization and transportation. Separate design from the workbench reduces damage to the bed when cutting heavy metal materials.

Gantry structure beams

Welded with high-quality materials, aging treatment, to ensure the strength needed for machine can also be lightweight, so that the machine has a better acceleration.

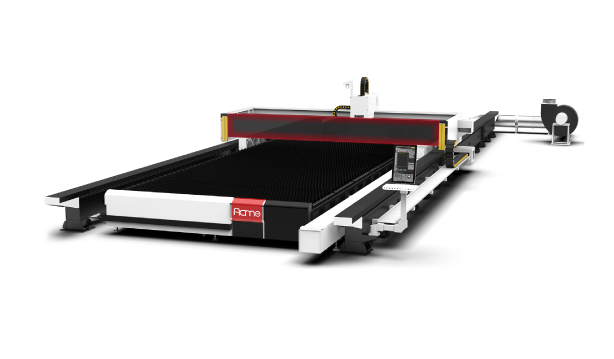

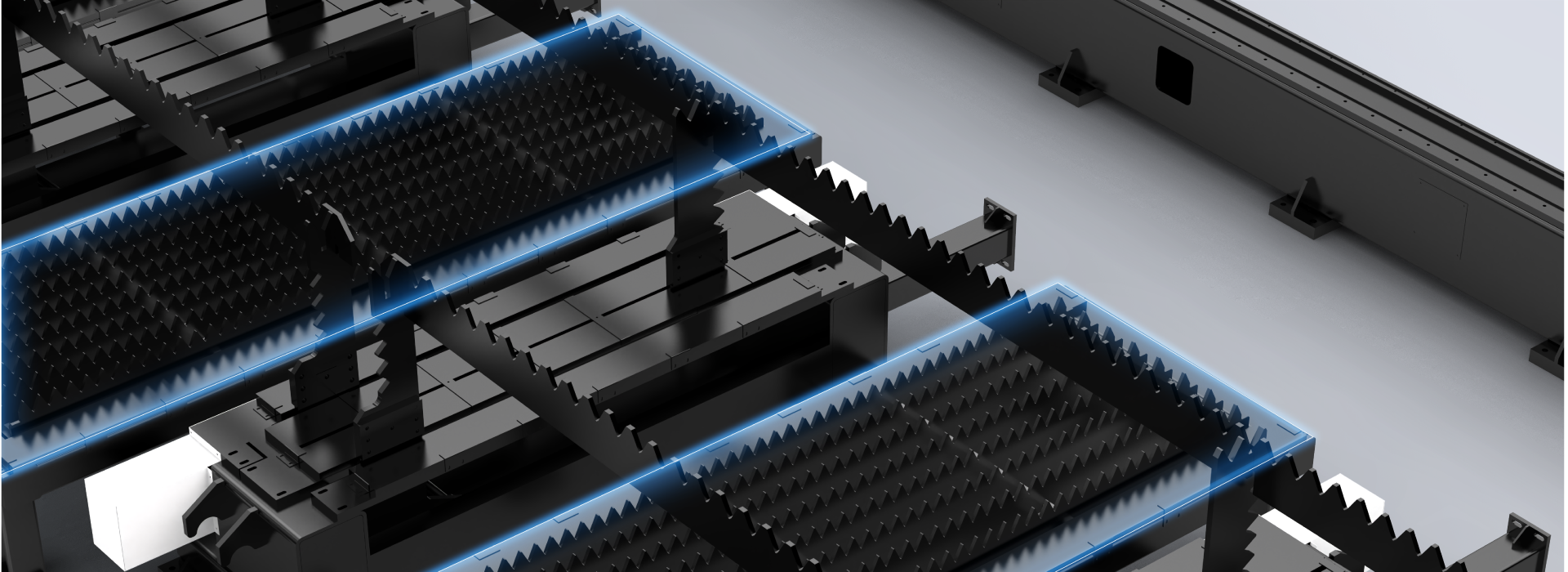

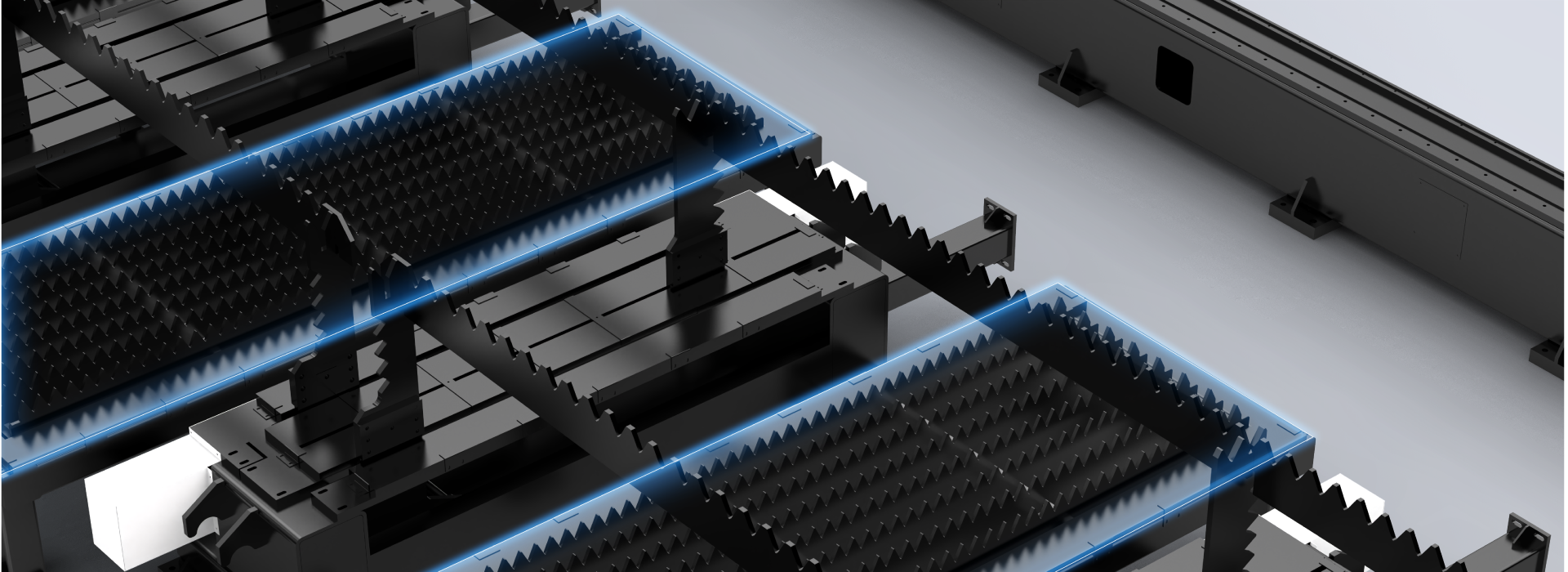

Cutting platforms

ACME’s profile support mechanism, consisting of rack, blade, etc., supports profiles, can be pneumatically aligned, high degree of automation, easy to use. Modular design, can be freely deployed, high flexibility.

Innovative technology

Bevel cutting

Zero tailing cutting

Visual positioning

Height following, cutting at any position

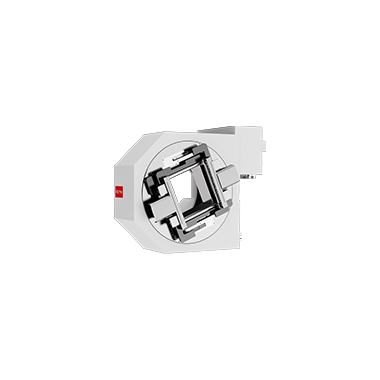

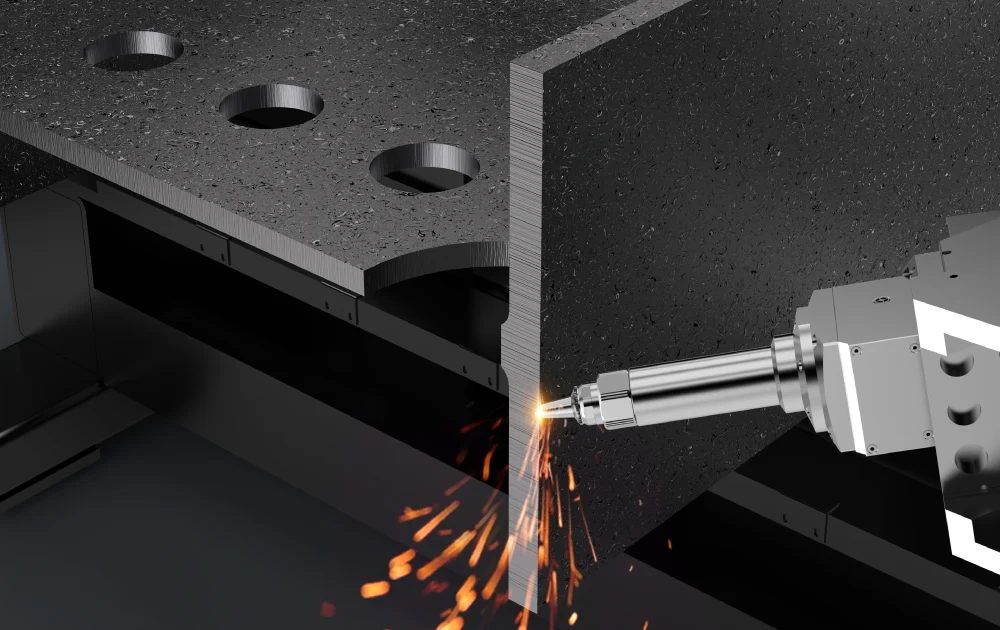

Bevel cutting

It adopts AB axis design dedicated for three-dimensional five-axis profile cutting, which can rotate well. The A-axis and B-axis can rotate ±90°. It’s fixed on the side for plates bevel cutting easily.

Zero tailing cutting

Unique structural design supports the whole cutting of raw materials, realizing zero tailing cutting and high utilisation of profiles;

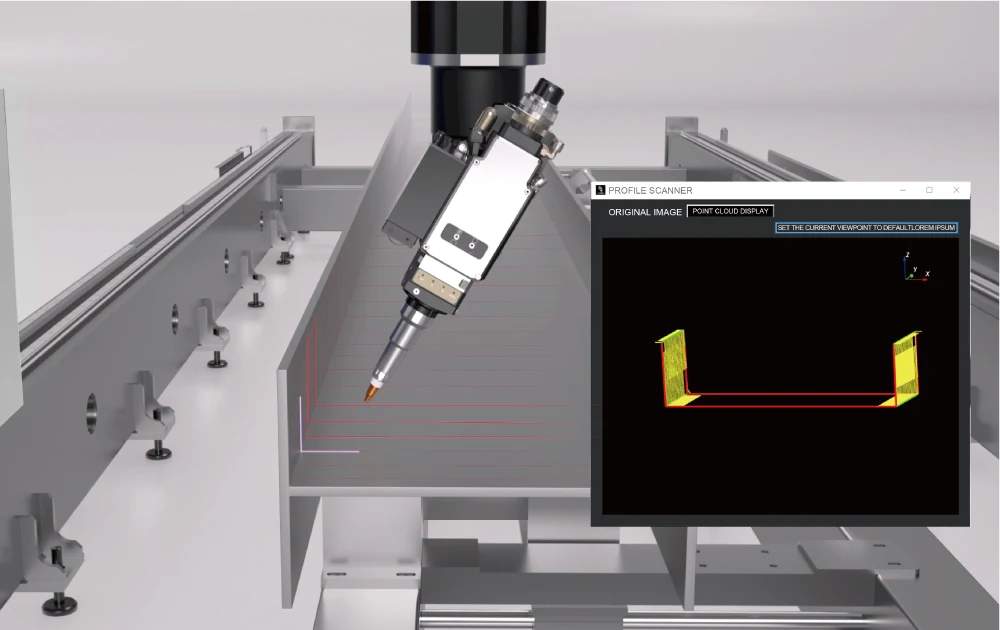

Visual positioning

Adapting contour scanner for visual positioning, measures and compensates for the deviation between the actual workpiece and the drawing, ensures processing accuracy and stability, and avoids the inconsistency between the drawing and the actual workpiece, such as cutting dislocation and non-vertical holes.

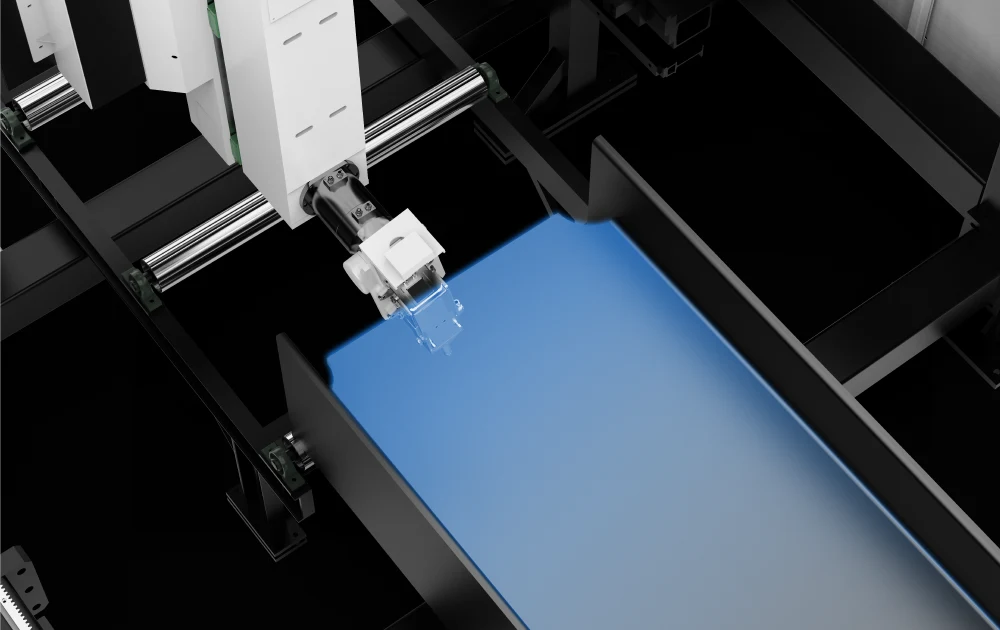

Height following

Support fixed height cutting and following outside the plate, cutting at anytime, anywhere

User-friendly design

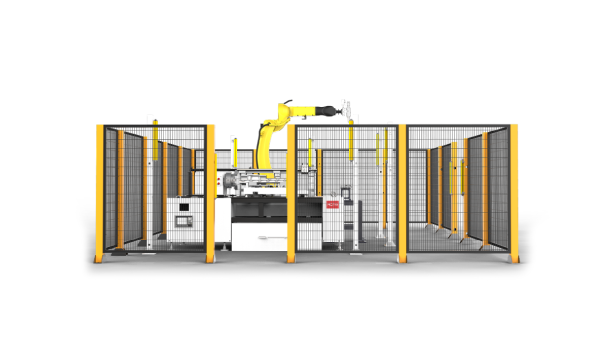

One machine having multiple cutting functions

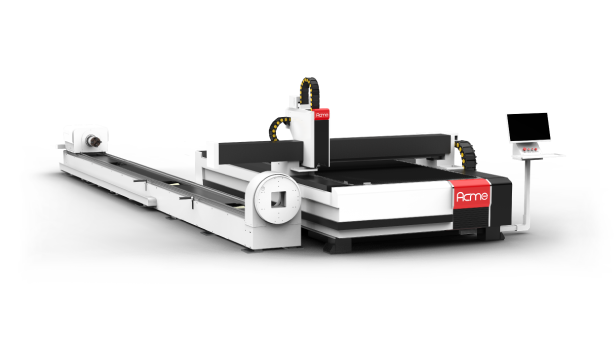

One machine support profiles cutting and profile bevel cutting, plane bevel cutting and 2D cutting

While one station is cutting, the other station can load and unload materials simultaneously, saving loading and unloading time, making processing flexible, supporting segmented and whole pipes processing.

The laser source, water chiller and machine bed are designed as separate parts and fixed on the ground. The machine has little loads while working and ensures cutting accuracy.

work station flow

Manual hoisting and loading

work station one

loading and unloading

work station two

search cutting materials, centering, and laser profiling ,cutting

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

What we can do

Savings in processes and costs

Laser cutting does not damage the surface of the material and cutting quality is good. The cutting section is smooth and burr-free, and one machine can complete multiple processes without sawing, drilling or deburring, which reduces processing time and the number of parts, decreases assembly errors and subsequent process workload.

Keep reading the Applications

industry cases

Steel structure

Support 3D bevel cutting,V-bevel Y-bevel X-bevel K-bevel and gradient cutting can be competent.

DISCOVER MORE

Elevators manufacturing

It can adapt to any metal pipe within 1.5 tonnes, all kinds of complex shapes and special materials processing needs.

DISCOVER MORE

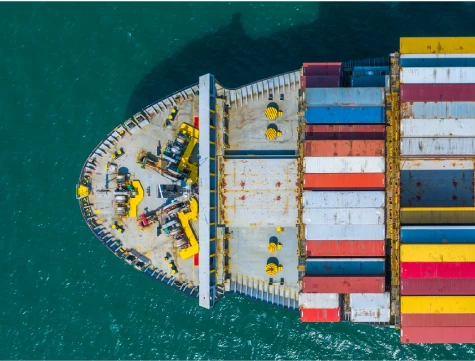

Shipbuilding

Good cutting section, improve welding quality and increase structural strength

DISCOVER MORE

Machinery industry

It can cutting heavy and long workpieces can be whole perforated cut off

DISCOVER MORE

"Now we have introduced a number of ACME laser tube cutting machines. During , we found that the efficiency is more than 20% higher than that of peers, the failure rate is also low, the operation is simple, and the maintenance is convenient. ACME's technicians trained for two hours, and our workers can operate independently. The after-sales service is even more considerate, the after-sales staff responds quickly, and the problem is solved efficiently. In short, ACME laser tube cutting machine is easy to use and economical."

The price is nice and it’s widely used

READ THE FULL STORY

At present, Dong Fang Hao Yu has purchased two professional laser tube cutting machines LT-9017ES from ACME, they have been serving good operation for customers for two years. These two devices have brought great convenience to the company's production and can meet the various photovoltaic bracket columns cutting needs, which is basically consistent with ACME's promise at the time.”

Brought great convenience

READ THE FULL STORY

"The heavy duty side-mounted machine of ACME, both in terms of performance and processing quality, can stand the test of time!"

improving labor production efficiency

READ THE FULL STORY

"Since purchasing ACME laser machine, our elevator production efficiency has been greatly improved, and the product quality has also been significantly improved. The cutting effect is exquisite and the processing flexibility is high, which has truly solved our problems!"

High-quality processing

READ THE FULL STORY

New Energy Industry

Photovoltaic Bracket Industry

Heavy machinery industry

Elevator manufacturing industry