ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

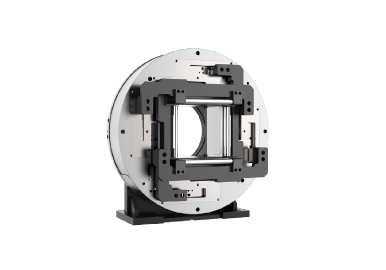

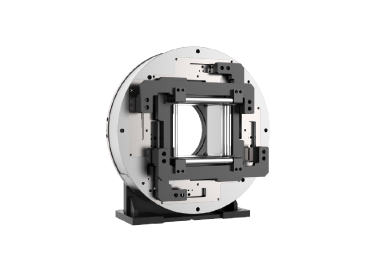

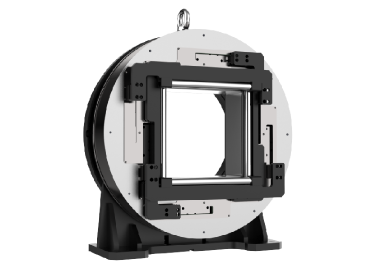

Heavy duty full stroke chuck

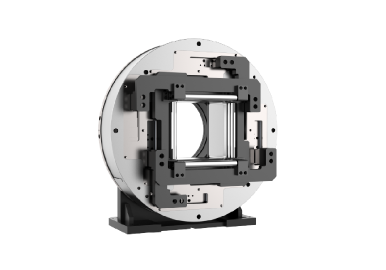

Three chuck

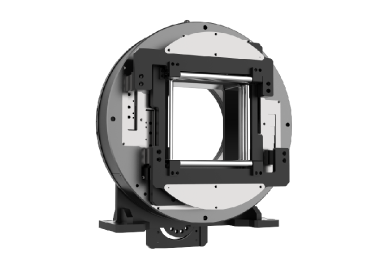

Four chuck

The chuck is one of the core components of the pipe cutting machine. The clamping force, rotation speed and intelligence affect the processing capacity directly. The chuck independently developed by ACME, it’s full-stroke pneumatic chuck, no need to replace the claws within the clamping range, improving production efficiency; Support to cut metal pipes and profiles with a weight of up to 4T and a length of 15m; the eight-cylinder design has a clamping force twice that of ordinary chucks. In addition, it has lots of advantages, such as high precision, fast response, strong load-bearing capacity, stable operation, and high dust-proof level. And each chuck and its part has a code to avoid the chuck being unable to be repaired after years of use.

Three model side-mounted heavy-duty chucks, low gravity center, much more stable operation. Equipped with high-precision servo motor and gear transmission, achiving multiple chucks rotate synchronously to improve cutting precision and speed. All three chucks are movable, and the middle chuck can move to the right side, allowing the last workpiece to be cut with high quality, achieving zero-tail cutting and reducing material waste.

Innovative four chucks design, the 3rd and 4th chucks are united to achieve double support. The loading part with 4-point support for stronger load bearing. Supporting the whole piece cutting of special process, realising zero tail material cutting and high tube utilisation. Multi-point clamping in the cutting area, cutting accuracy is improved oberviously.

Clamping range:

8-120mm

Chuck speed:

200 (r/min)

Clamping range:

10-180mm

Chuck speed:

120(r/min)

Clamping range:

10-230mm

Chuck speed:

100r/min

Clamping range:

15-250mm

Chuck Clamp Force:

200kg

Clamping range:

15-280mm

Chuck Clamp Force:

200KG

Clamping range:

30-350mm

Chuck Clamp Force:

500KG

Clamping range:

70-540mm

Chuck Clamp Force:

1600KG

We are a well-known professional manufacturer of tube laser cutting machine in China, have devoted ourselves to the manufacture of high power bevel Tube cutting machine early.

ACME own-designed pendulum head bevelling structure, ordinary laser head can also achieve multi-angle high-precision bevelling ±45°cutting, not only for workpiece cutting, but also for

welded tubes bevel cutting without secondary processing, which improves tube utilisation and bevel-cutting yield, at the same time reducing production costs. It is also friendly for special processes.

We has a large customer base in the heavy Tube cutting industry, such as steel structure, shipbuilding, new energy, photovoltaic, petroleum and other heavy-duty Tube cutting industry.

ACME jointly with famous brand Bochu developed the bevelling system;

Bevel drawings generated with nesting software to achieve tupe parts bevel cutting;

Double Y axis cutting to improve the cutting accuracy of heavy pipes;

Zero tail material cutting to improve the utilisation of tubes;

Support 12000~60000W intelligent cutting;

ACME is based on customer needs and continuous innovation to provide comprehensive solutions for metal processing for customers worldwide.

The equipment has a small Y-axis with a stroke of 300mm, when cutting heavy pipes, the pipe does not move and the cutting head moves along the pipe, which can obviously reduce the fluctuation range of the pipe, improve the processing accuracy and shorten the processing time.

It is very friendly for cutting dense holes, and the advantages are even more obvious with long term using;

Especially facing with a large number of shapes that take a long time to cut, it's faster;

Pipe cutting in a stationary state can significantly reduce the range of pipe fluctuations and improve processing accuracy;

emergency stops are reduced, the working process is softer, and the guide rails and racks can be better protected;