Find your machine

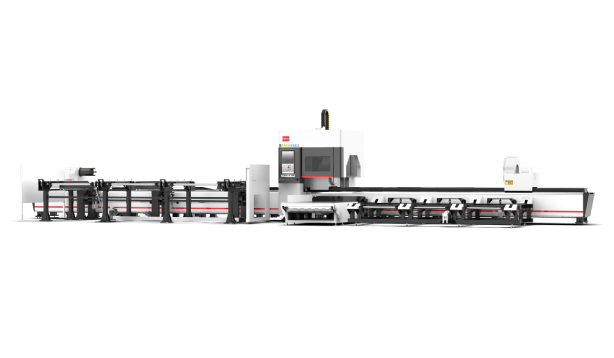

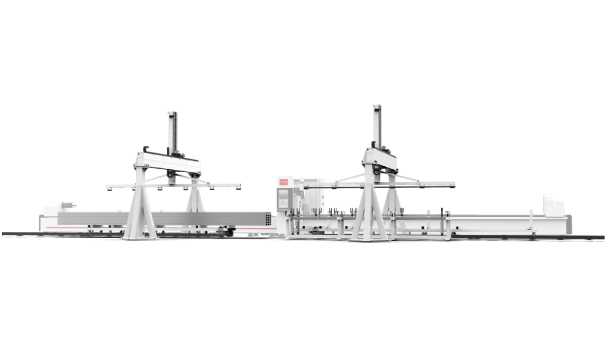

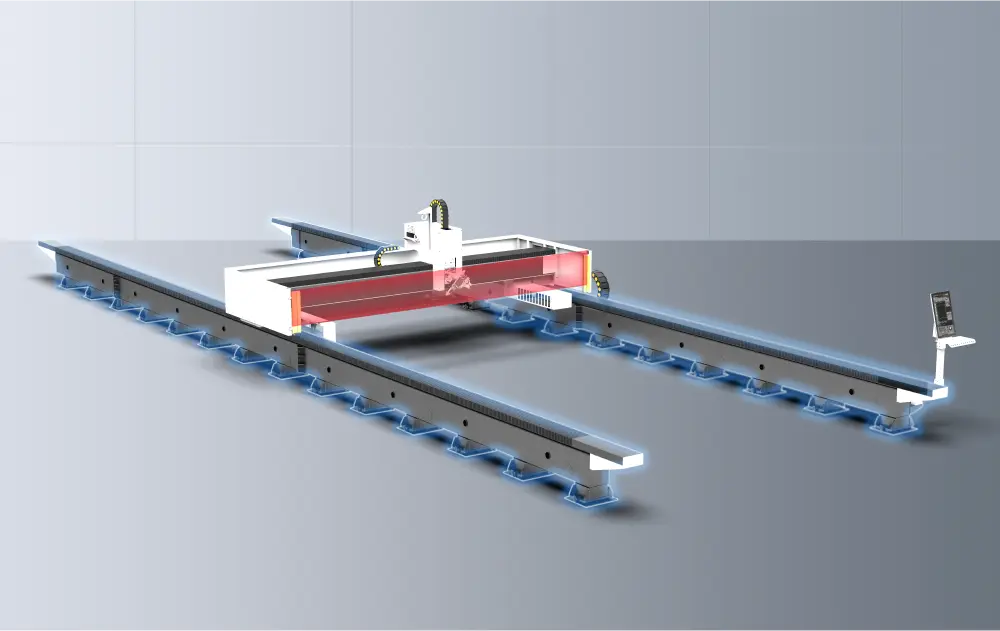

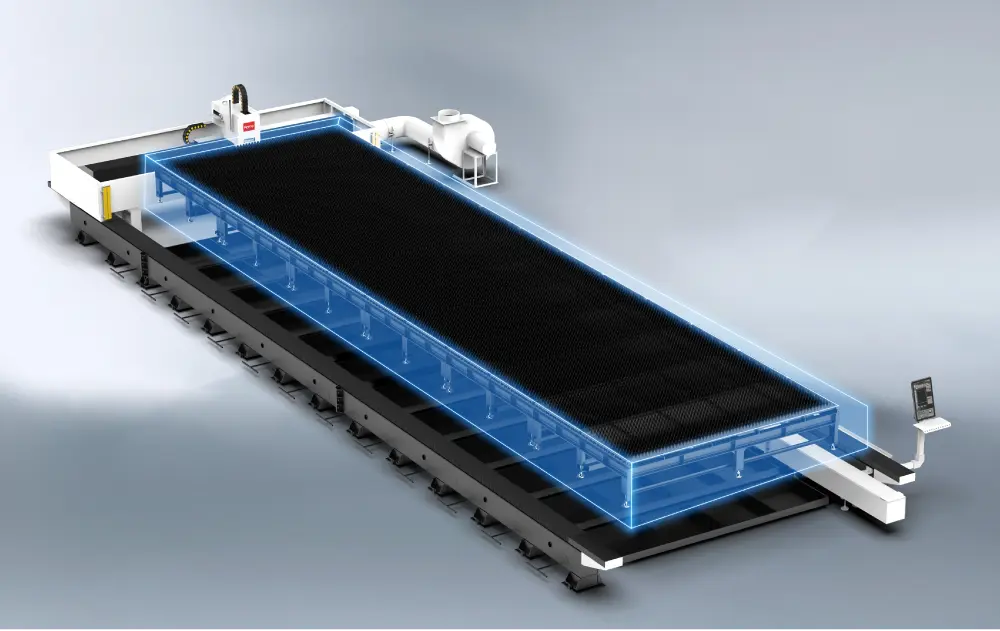

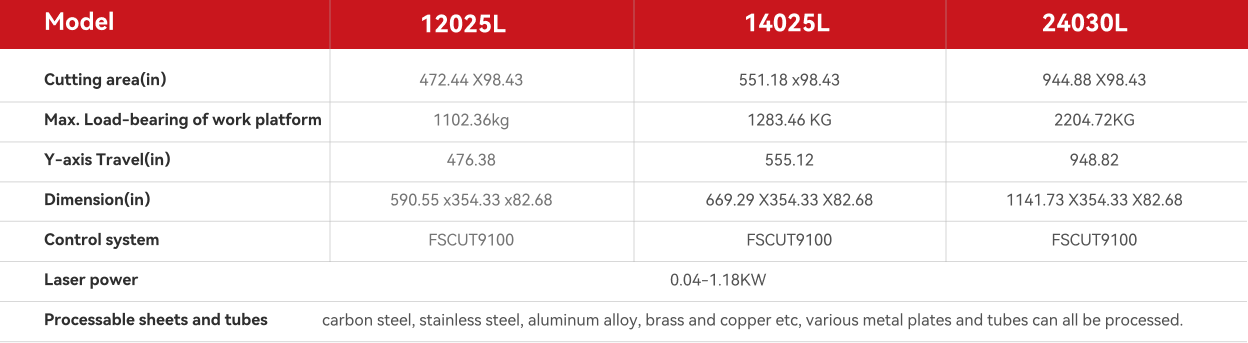

The standard size of L series models is 12*2m, with a length of 12m, 14m, 16m, 24m... etc., with a width of 1.5m, 2m, 2.5m, 3m, 3.5m etc. (support customization).

please check your equipment information.

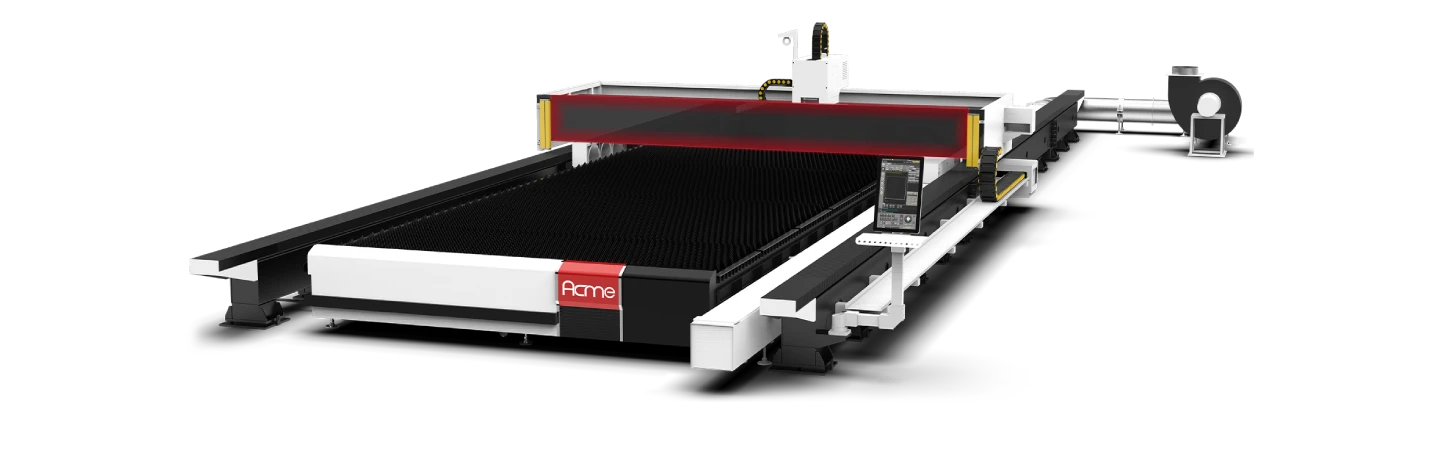

12020L

14025L

16030L

24035L

Reasons to choose Acme L-series

1

Cutting ability

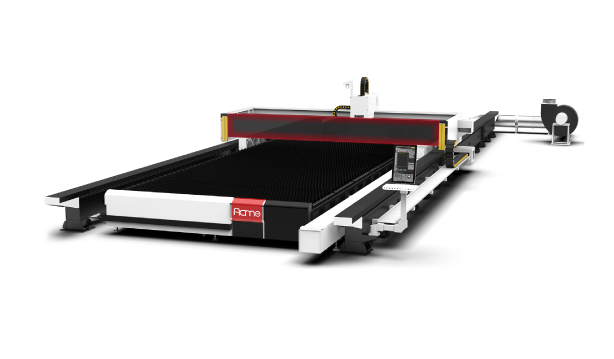

L series of ground rail laser cutting machines can cut metal sheets with a length of 12+ N meters, a width of 2-3.5m, and a thickness of 100mm or less.Although the initial investment is high, the service life is long and the long-term return rate is high. It’s perfect substitute for plasma and flame cutting machines.

2

Supports customization

From 12kw to 60kw, high-power lasers have high photoelectric conversion rates, reducing electricity costs;

3

Adopt air cutting

Save gas consumption such as oxygen and nitrogen, reducing some costs;

4

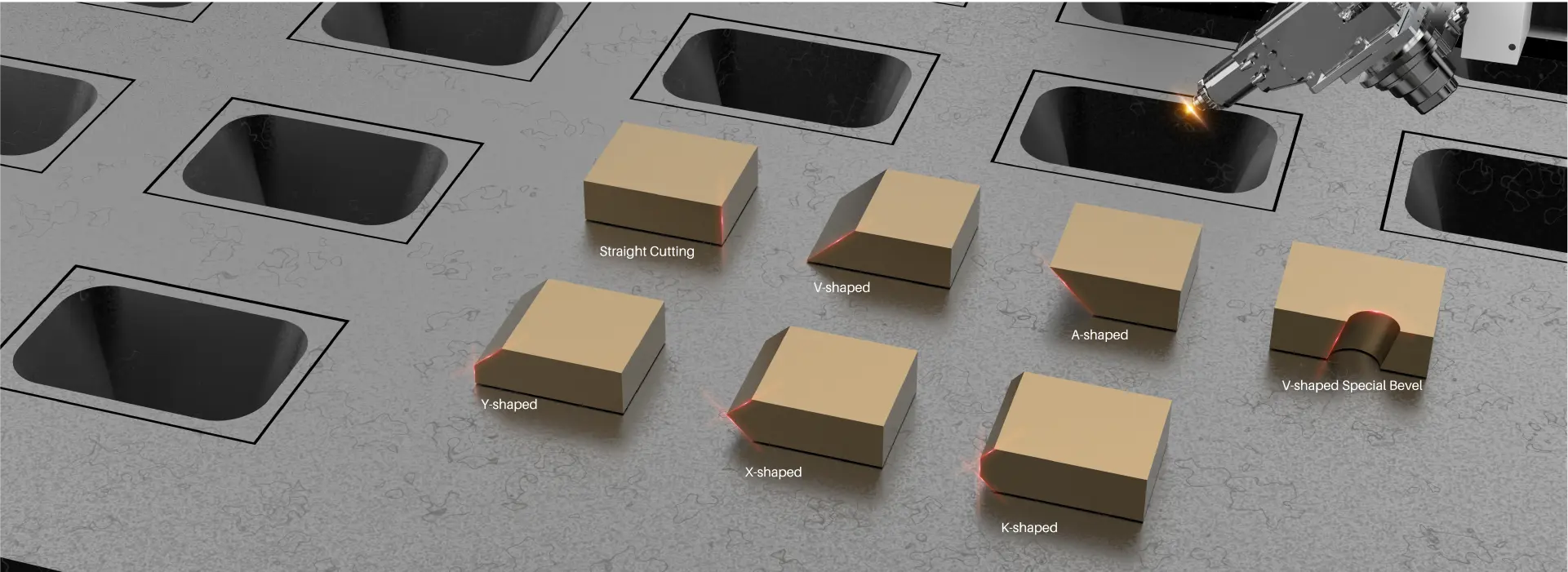

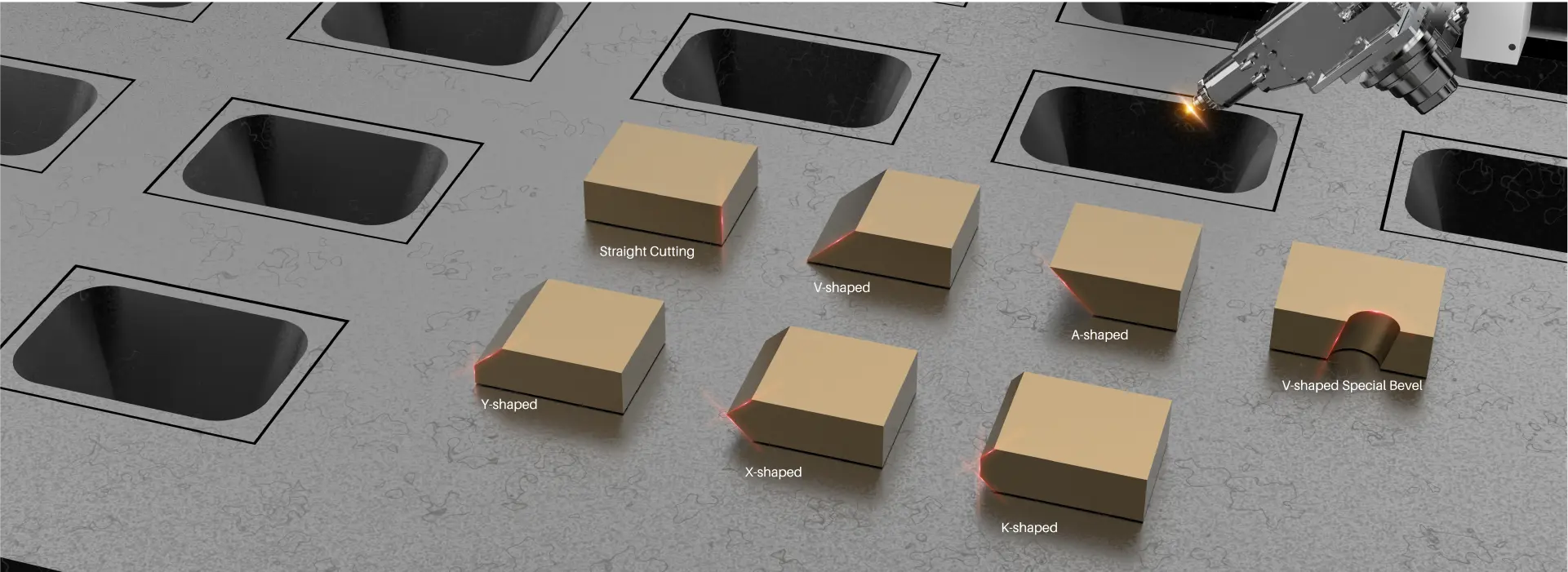

Support conventional bevels

Such as A, V, Y, X, K, and special bevels such as intersection and gradient;

5

Saving equipment investment

Fast cutting speed, narrow slit, smooth cutting surface, no slags, one-time molding without secondary processing;

Performance configuration

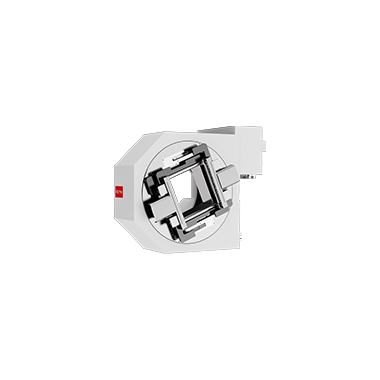

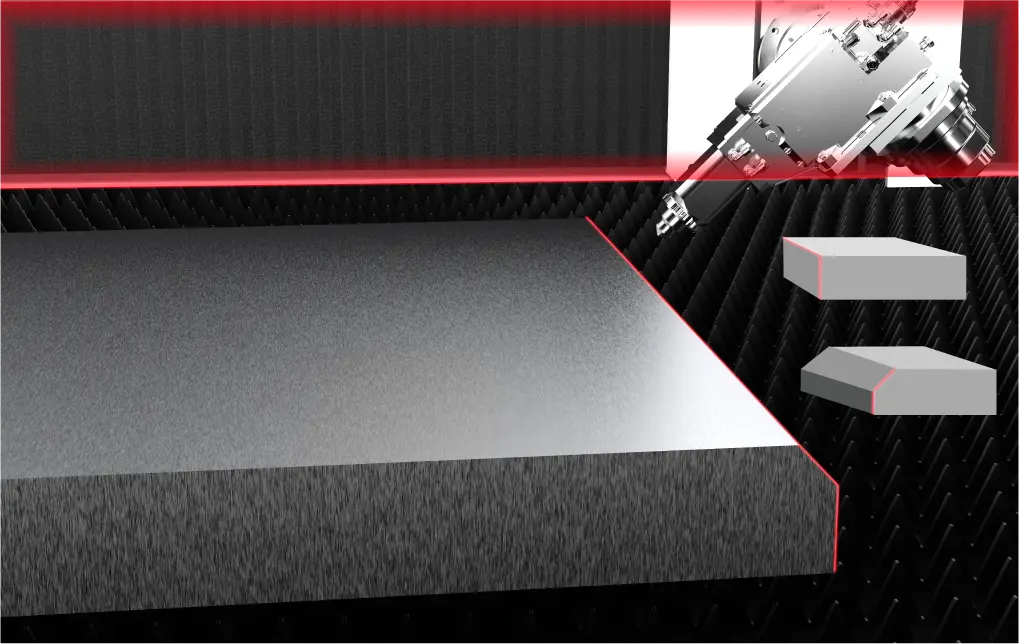

Excellent bevel cutting

Supports common bevel cutting such as V, Y, X, K and gradient bevel. No need secondary processing, which is convenient for subsequent assembly or welding and reduces production costs;

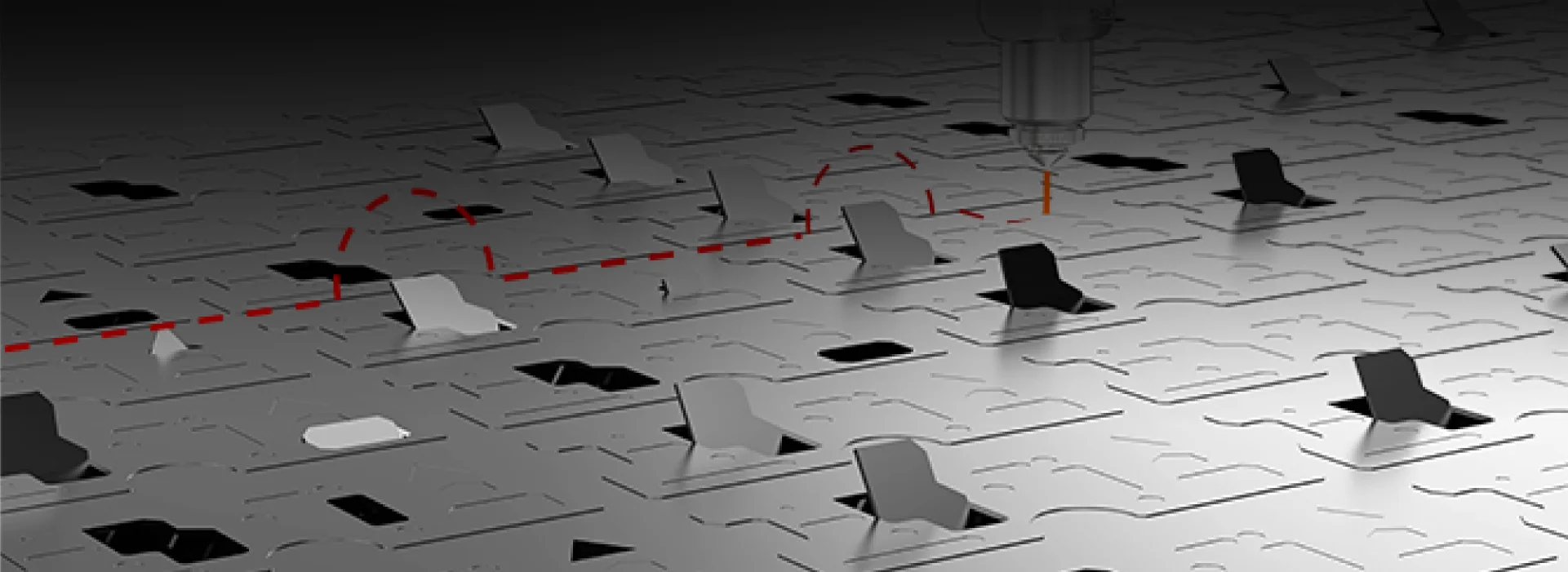

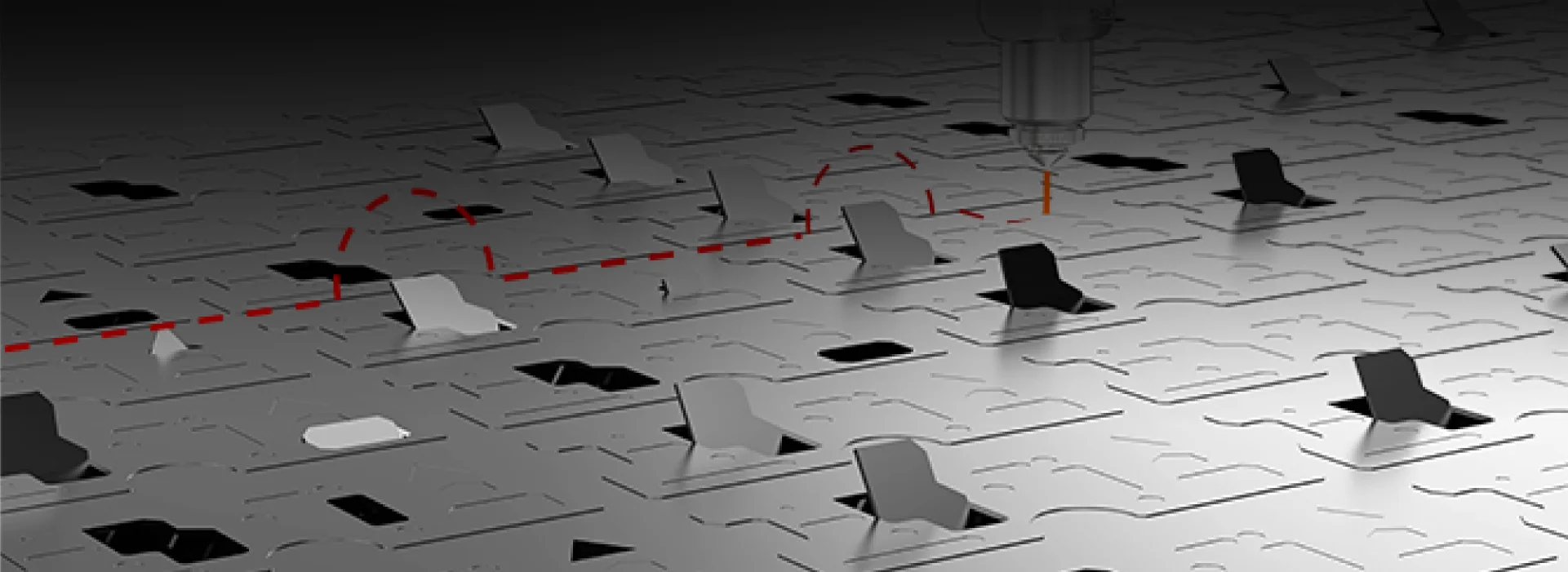

Active avoid collision system

Capacitive sensing, fast response speed, can quickly detect potential obstacles such as tilted parts, automatically avoid potential collisions, reduce the risk of laser head collision caused by work-piece tilting, etc., and ensure continuous and stable cutting.

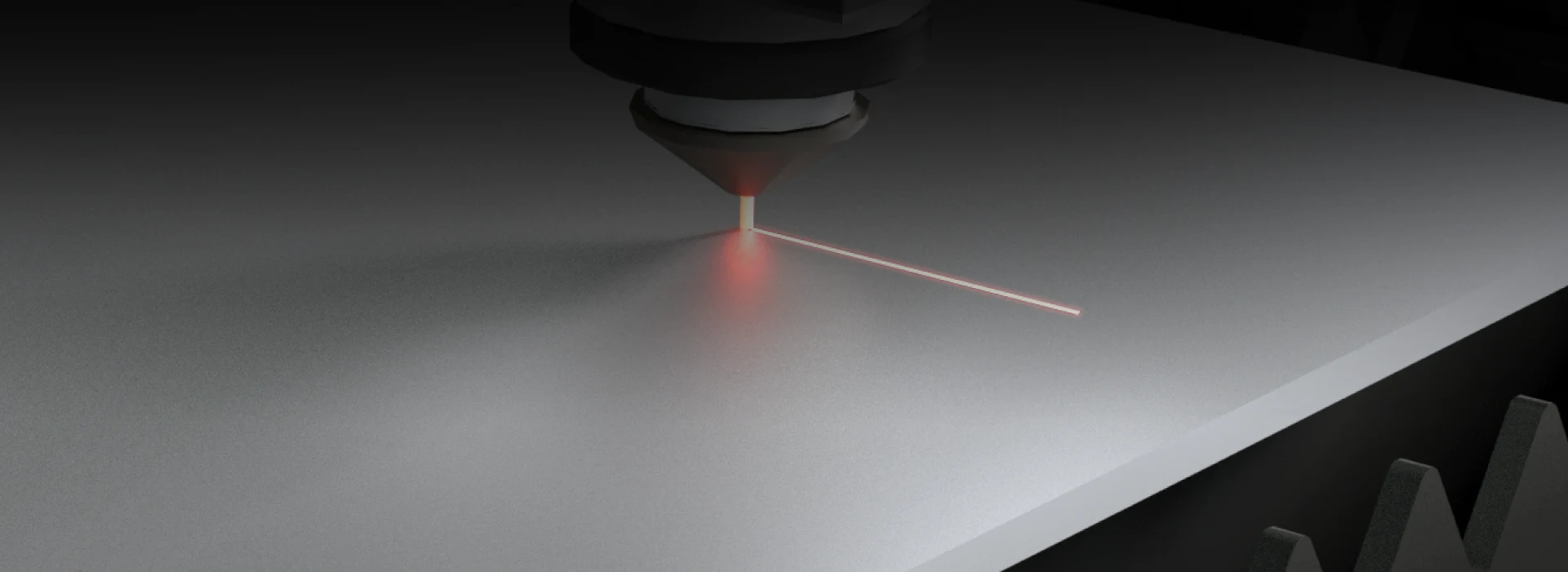

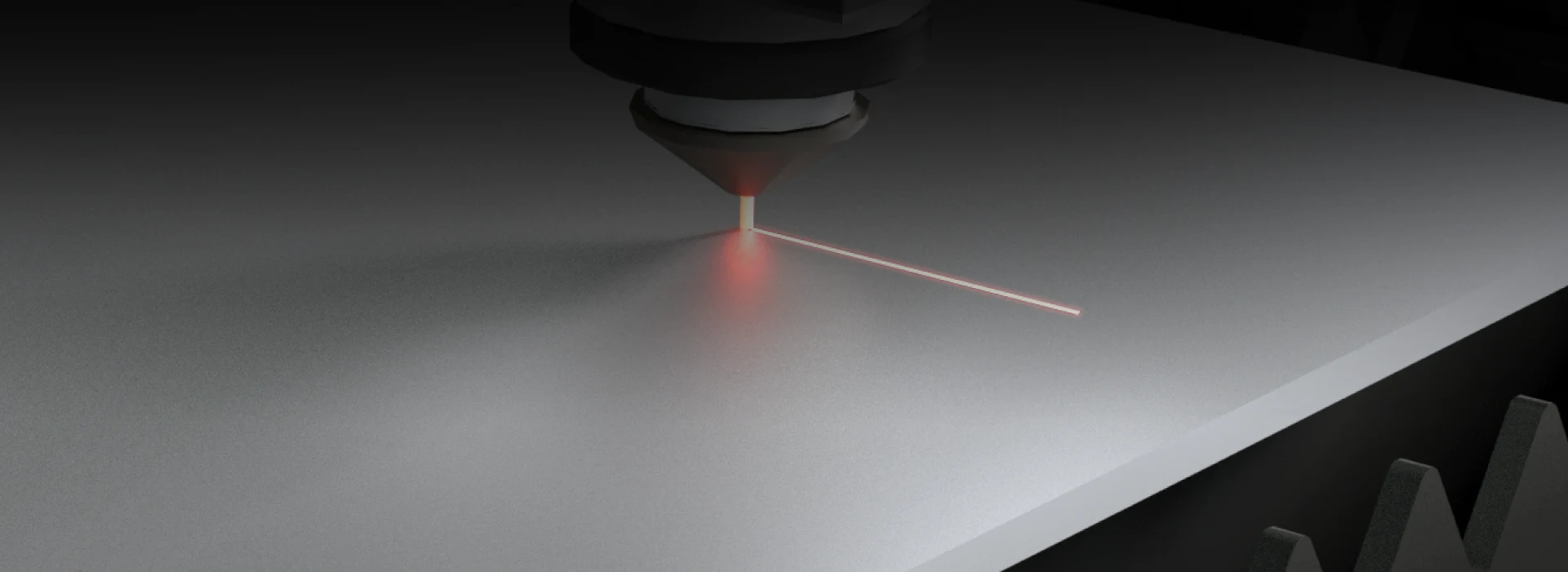

Flash piercing technology

Fast frequency conversion piercing is synchronized with the movement of the cutting head and improve the piercing efficiency.

Innovative technology

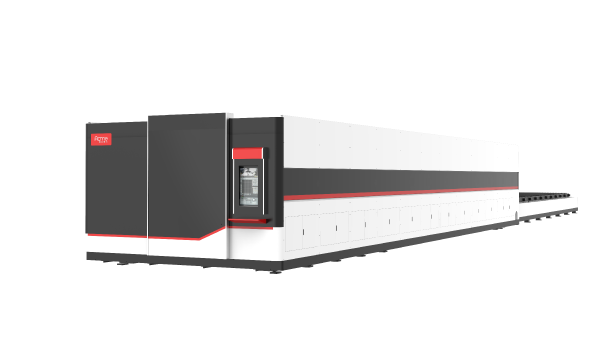

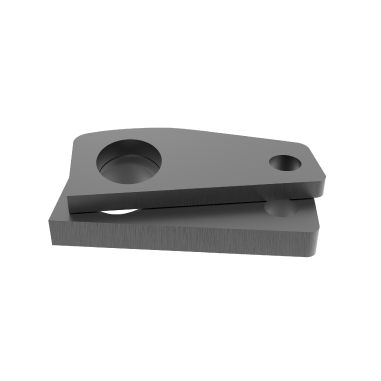

Modular machine bed

Versatility

Ingenious design

Modular machine bed

Based on the 12m machine bed, we can do customization as your requirements, such as 12+N m. Ultra-large format design, safe and durable, high cost-effective!

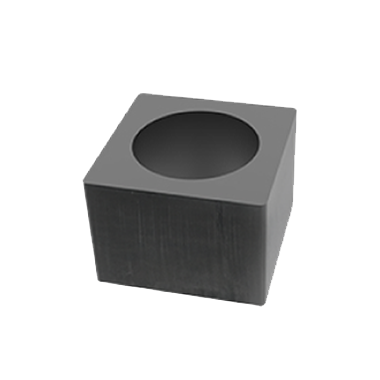

Versatility

The foundation of the ground rail cutting machine is compatible with the original flame cutting machine, saving time and cost.

Ingenious design

The working platform and machine bed are separated, and the operation is stable. It can be used under harsh environment, with long service life and high cost-effective.

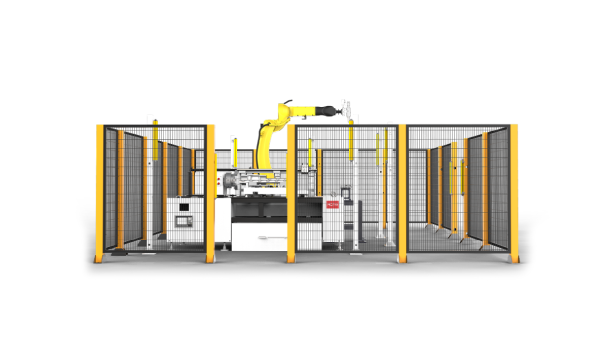

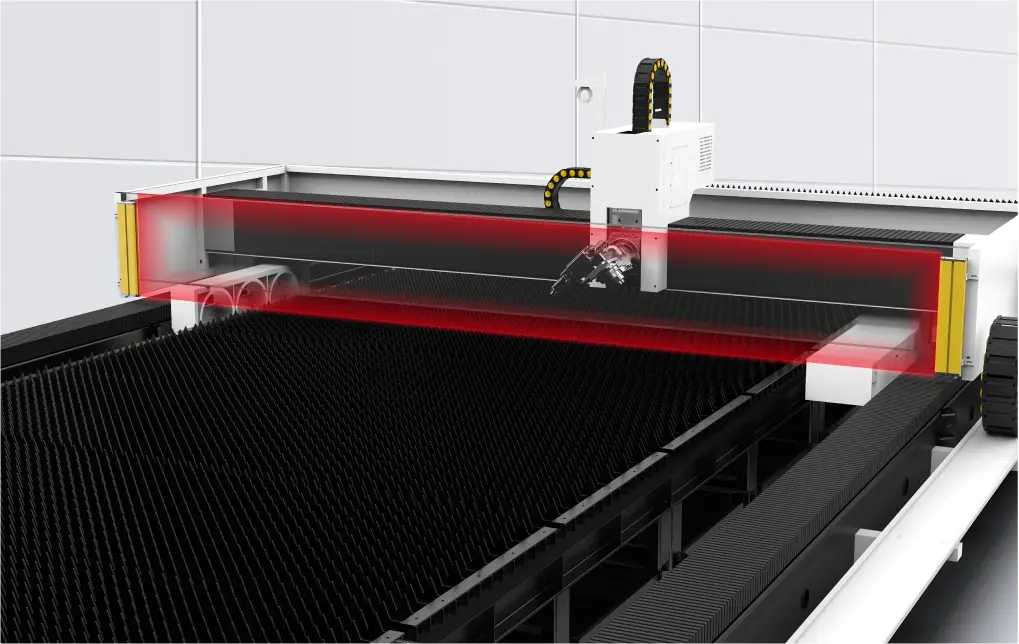

User-friendly design

Install safety protection grating. When the system detects an object in the safety area of the beam, it will immediately trigger emergency braking to protect personnel and equipment.

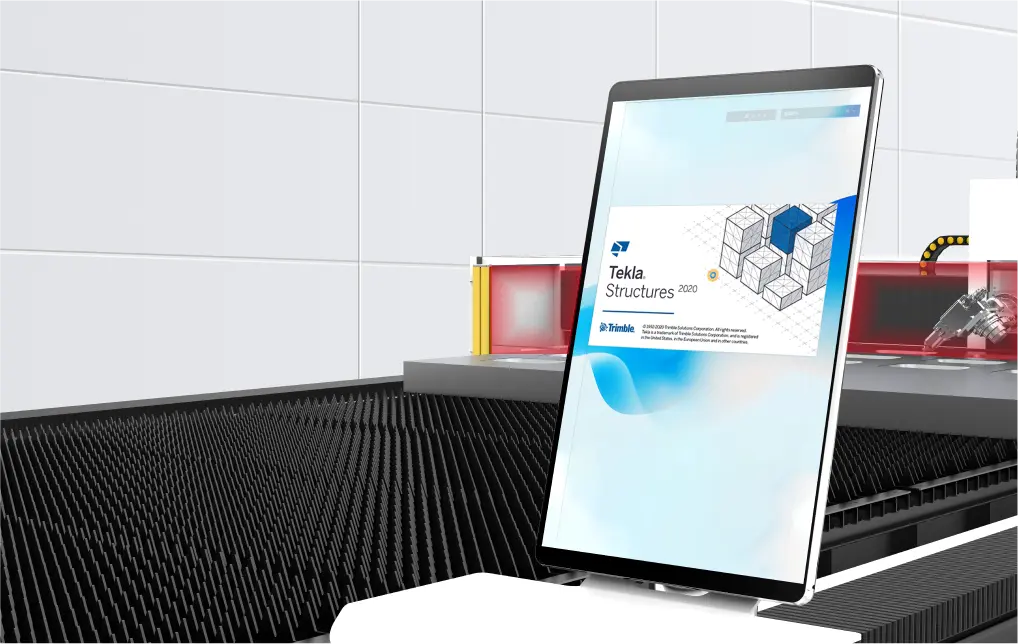

It can dock various overlapping forms of bevel cutting processes and support TEKLA 3D modeling data file cutting;

It supports bevel cutting for workpiece that has been straight-cut and shaped, saving materials

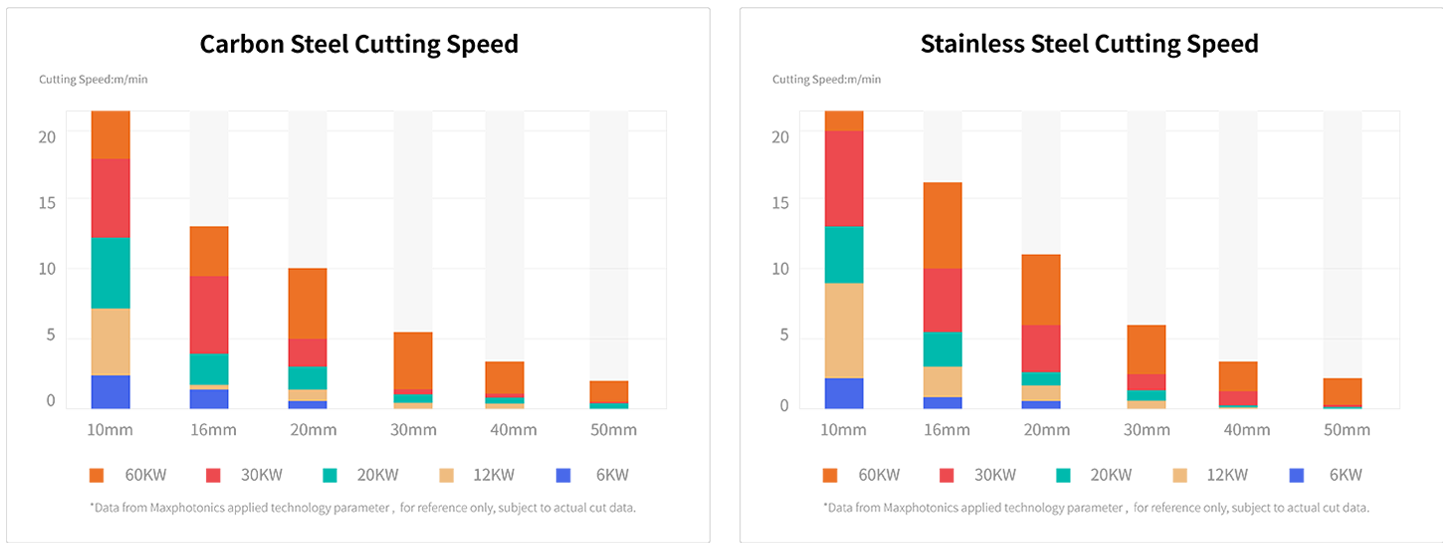

High power production efficiency comparison sheet

12KW, 20KW, 30KW, 40KW, 60KW Cutting Speed Comparison

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

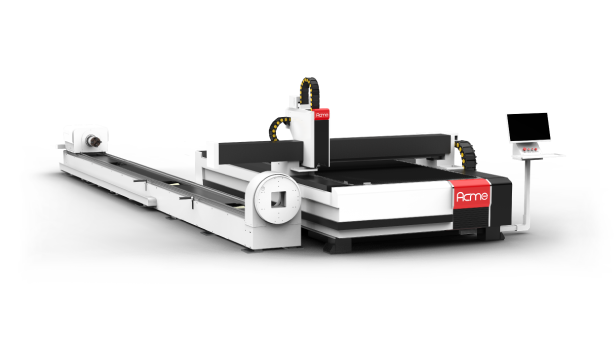

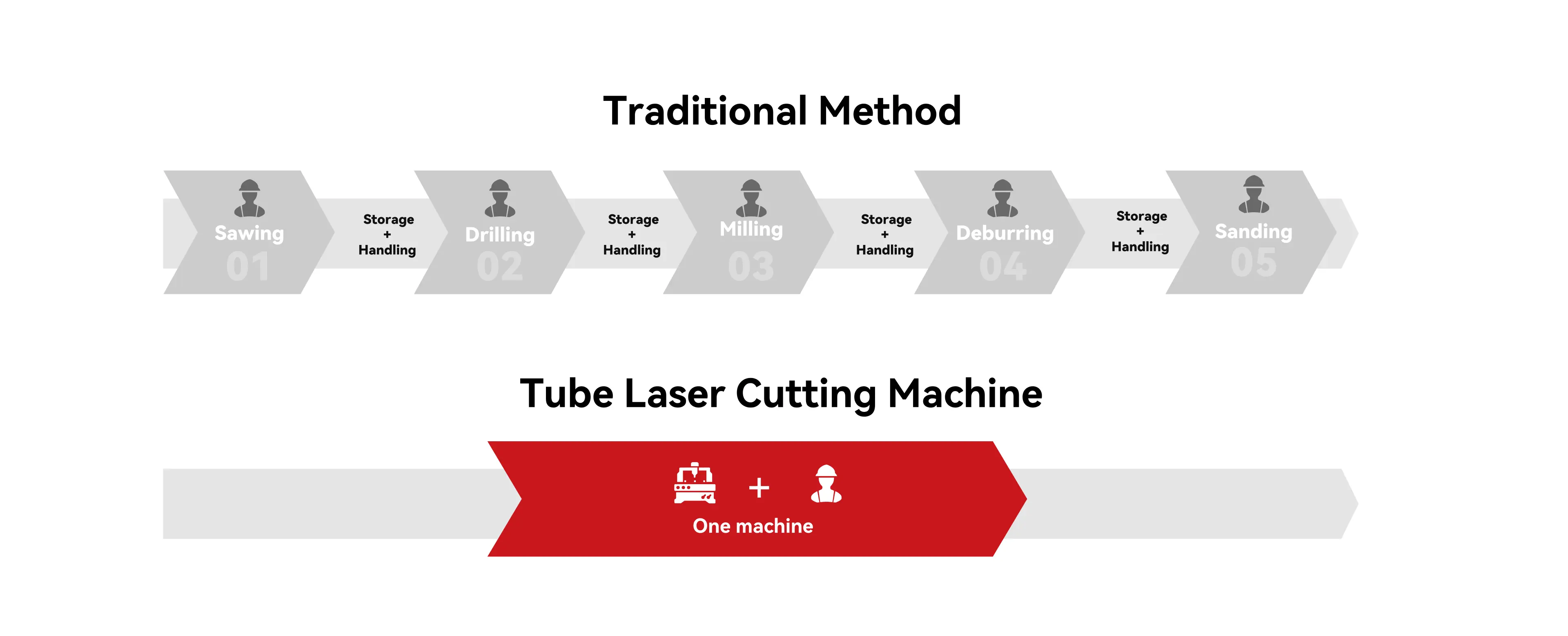

Reasons to choose Acme T-series

Savings in processes and costs

The cutting section is smooth and burr-free, and one machine can complete multiple processes without sawing, drilling or deburring, which reduces processing time and the number of parts, assembly errors and downstream process workload.

Keep reading the Applications

industry cases

New energy industry

It can effectively reduce the processing error and improve the processing precision.

DISCOVER MORE

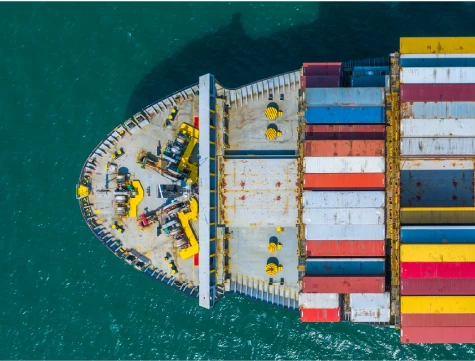

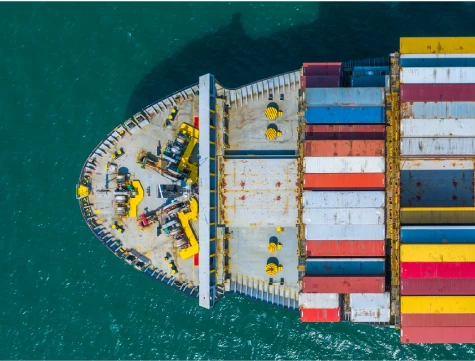

Shipbuilding

Good cutting section, improve welding quality and increase structural strength

DISCOVER MORE

Steel structure

Support 3D bevel cutting,V-bevel Y-bevel X-bevel K-bevel and gradient cutting can be competent.

DISCOVER MORE

Machinery industry

It can cutting heavy and long workpieces can be whole perforated cut off

DISCOVER MORE

"Now we have introduced a number of ACME laser tube cutting machines. During , we found that the efficiency is more than 20% higher than that of peers, the failure rate is also low, the operation is simple, and the maintenance is convenient. ACME's technicians trained for two hours, and our workers can operate independently. The after-sales service is even more considerate, the after-sales staff responds quickly, and the problem is solved efficiently. In short, ACME laser tube cutting machine is easy to use and economical."

The price is nice and it’s widely used

READ THE FULL STORY

"The heavy duty side-mounted machine of ACME, both in terms of performance and processing quality, can stand the test of time!"

improving labor production efficiency

READ THE FULL STORY

"ACME has won the bid for heavy tube laser last year and the machine has produced for us more than one year. We found that it has stable performance and high efficiency, and its production capacity is twice than the original traditional cutting method. During processing period, the communication with ACME was very smooth. At the beginning of this year, ACME won the bid for 2 more machines, I believe that these two new equipment will also bring good results!"

New quality productivity

READ THE FULL STORY

“ Since we used ACME Laser’s machine, the tubes cutting accuracy and efficiency in ship manufacturing have been significantly improved, solving many previous problems and making our production smoother and more efficient.”

Enhancing the quality of parts

READ THE FULL STORY

New Energy Industry

Heavy machinery industry

Steel structure innovation industry

Shipbuilding industry