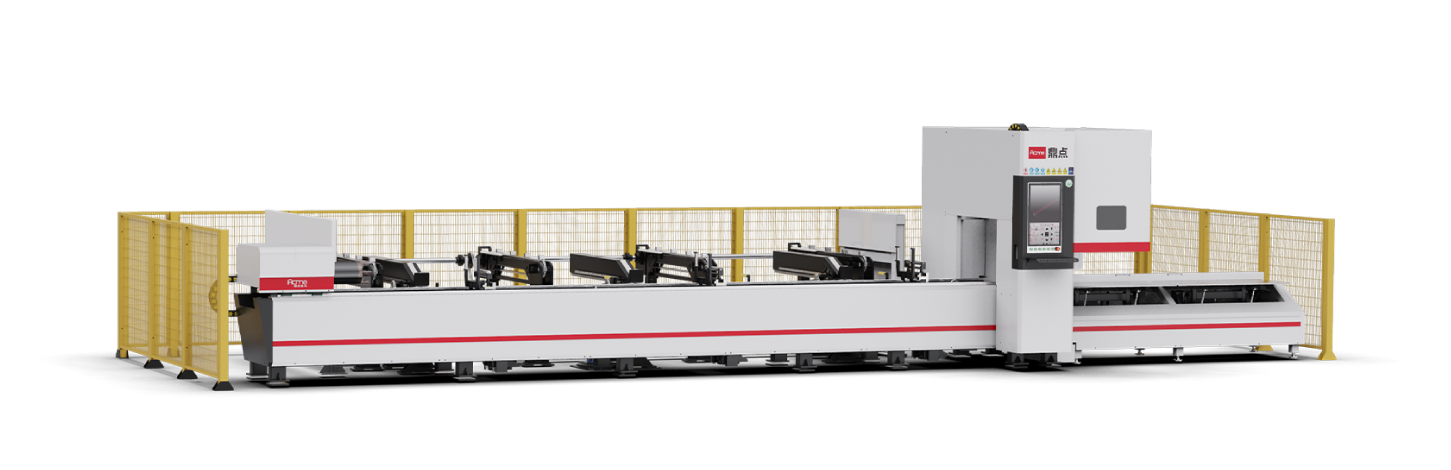

Find your machine

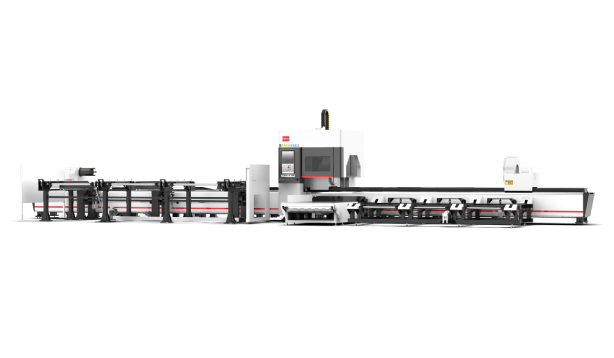

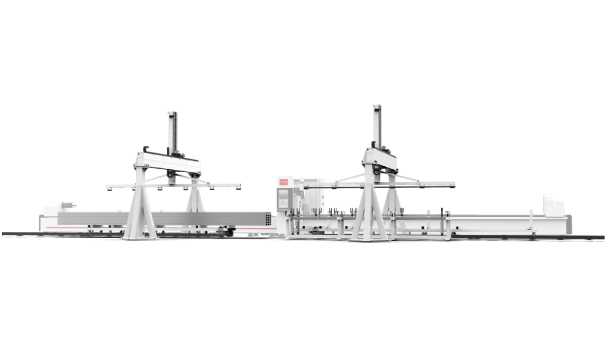

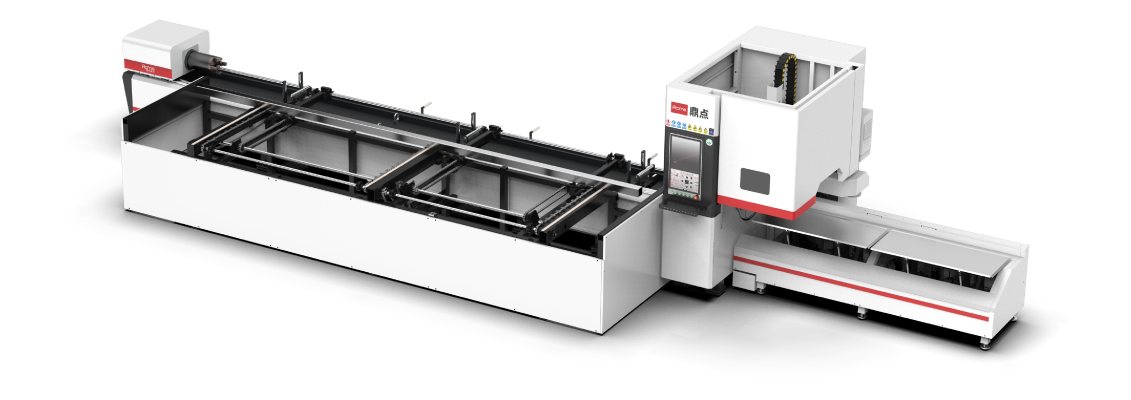

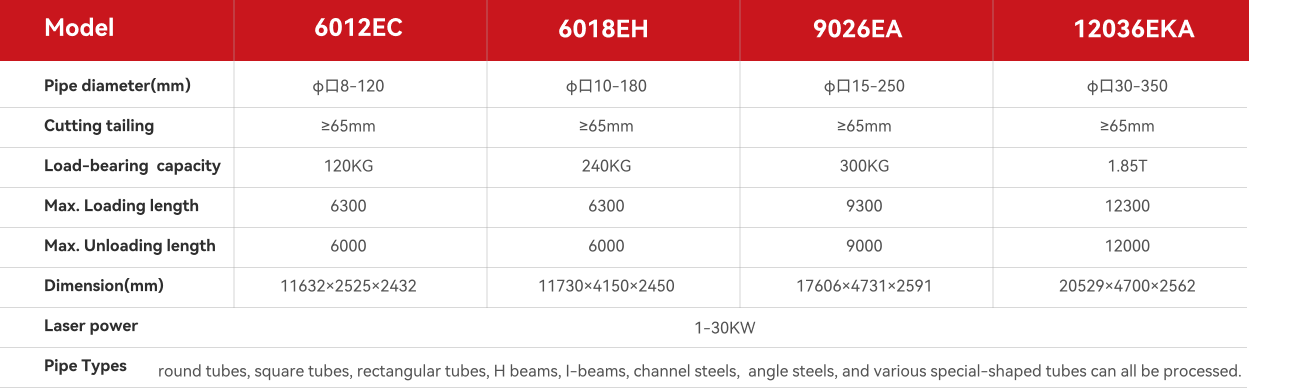

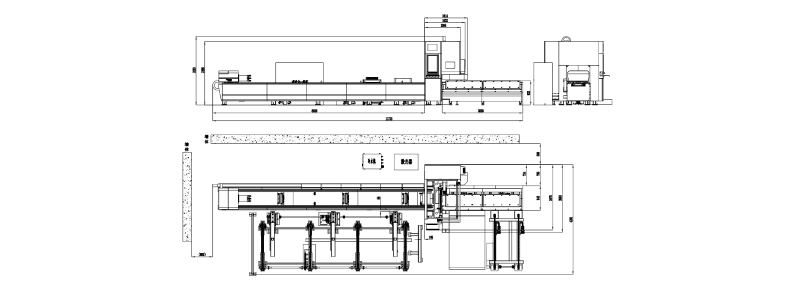

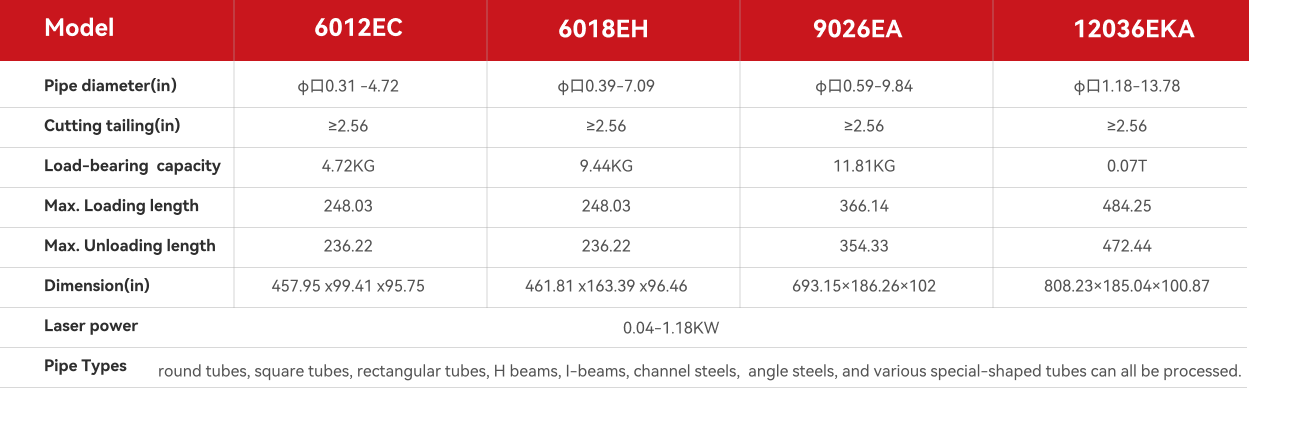

Bed sizes for the E-Series models are based on 6m as standard, with 6m, 9m, 12m bed sizes available as options, the chucks number as shown on the right.

please check your equipment information.

E120

E180

E230

E260

E280

E360

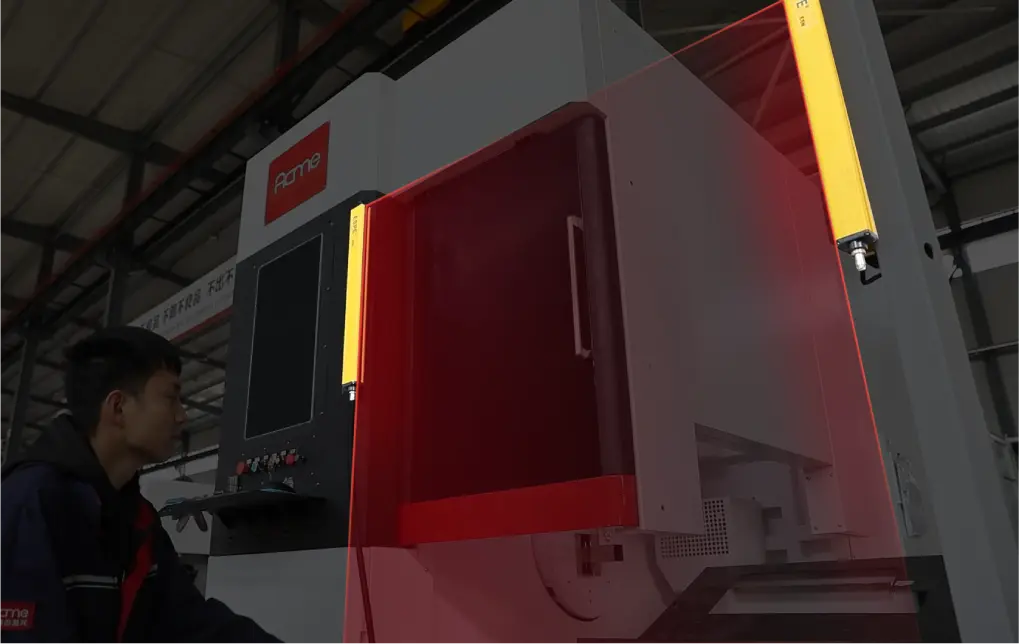

Reasons to choose Acme E-series

1

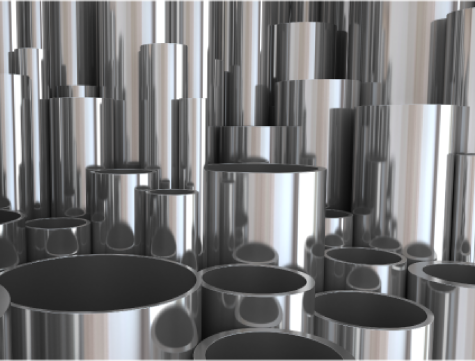

Cutting ability

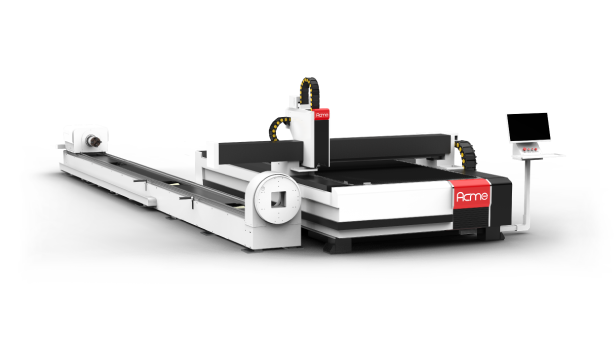

E-Series high efficient laser Tube cutting machine, can cut any metal Tubes, with the length of 6-12m, the diameter 8-350mm, and the weight of 1.5 tons or less;

At least 10 sets E-series machines are in production every day in the workshop, which can quickly manufacture precision parts and accurately cut complex graphics. The design schemes are diverse and flexible, meeting various metal processing needs. At the same time, we are the first manufacturer to independently develop and manufacture servo supports, which solves the problem of loading support and has higher precision and efficiency.

2

Chuck technology

square hole design, strong Tube passing rate, achieving the widest working range, helping reduce equipment investment;

3

High dynamic performance

machine with 120mm chucks, chuck moving speed 110m/min, speed 200r/min, acceleration 1.5G;

4

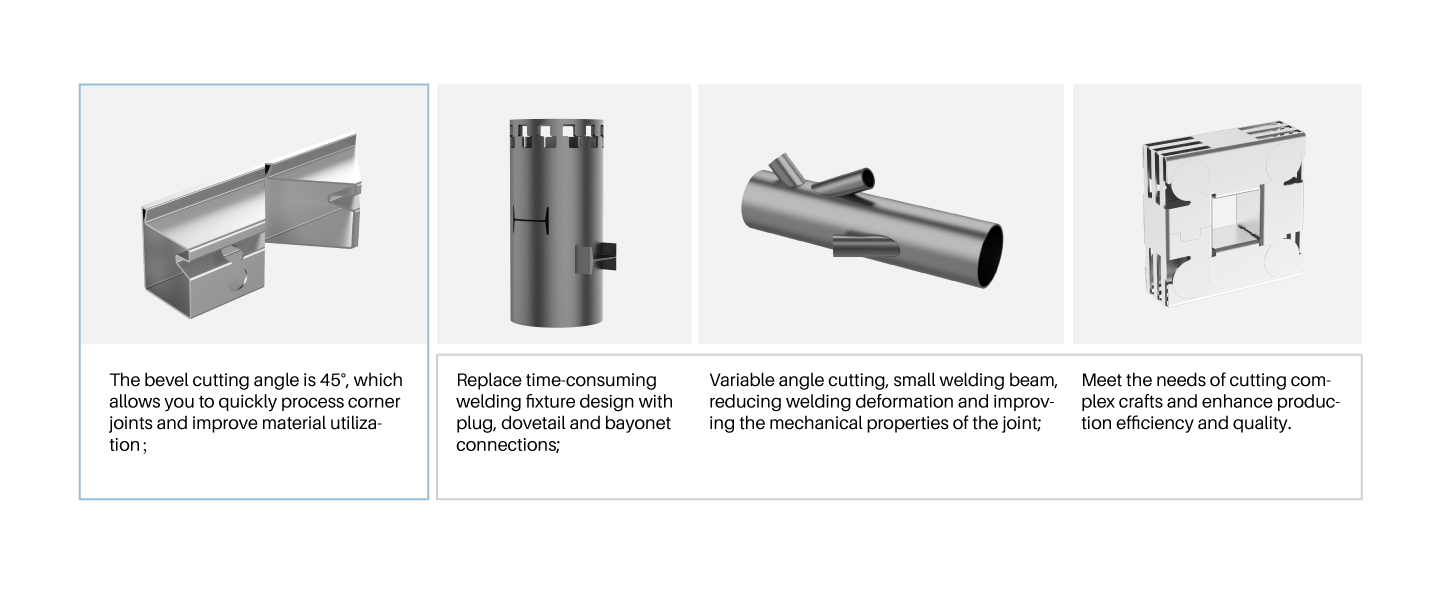

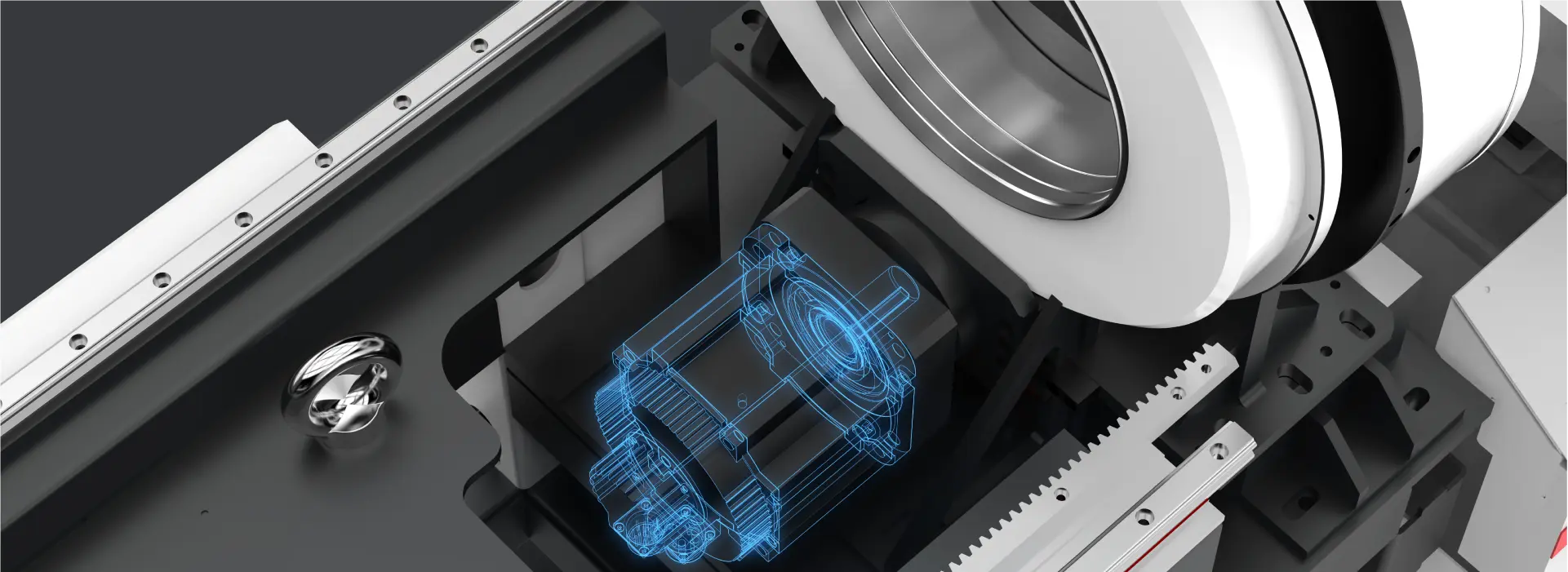

More ACME self-developed technologies

mortise and tenon structure bed, segmented servo support, automatic unloading device, etc., to ensure cutting accuracy;

5

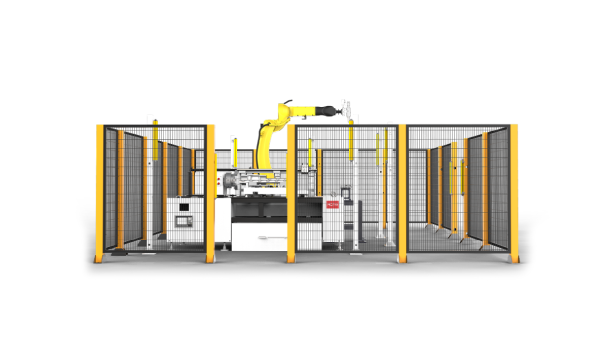

User-friendly design

weld identification, safety light curtain, dust removal design, etc. well protect workers, machines and work-pieces

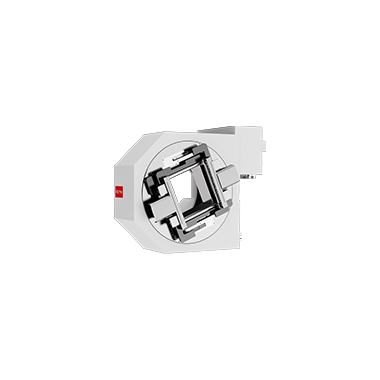

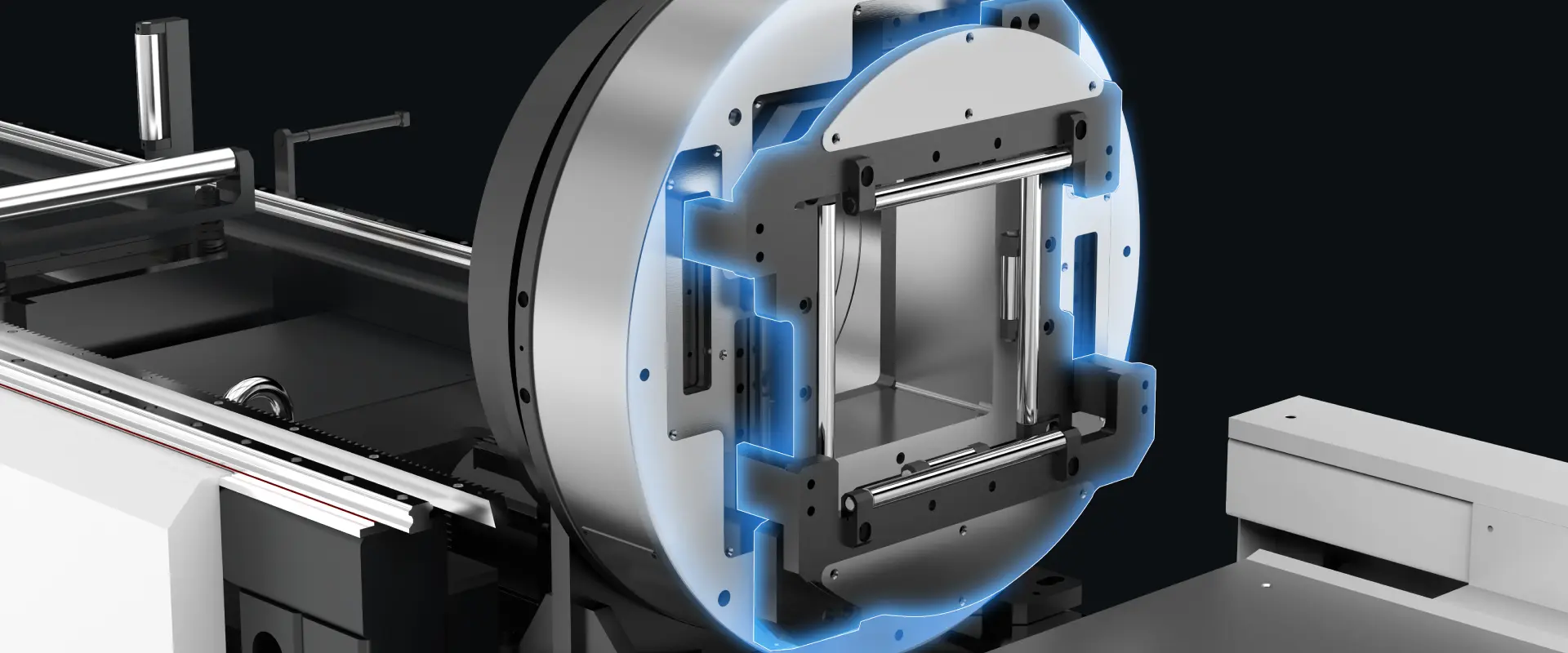

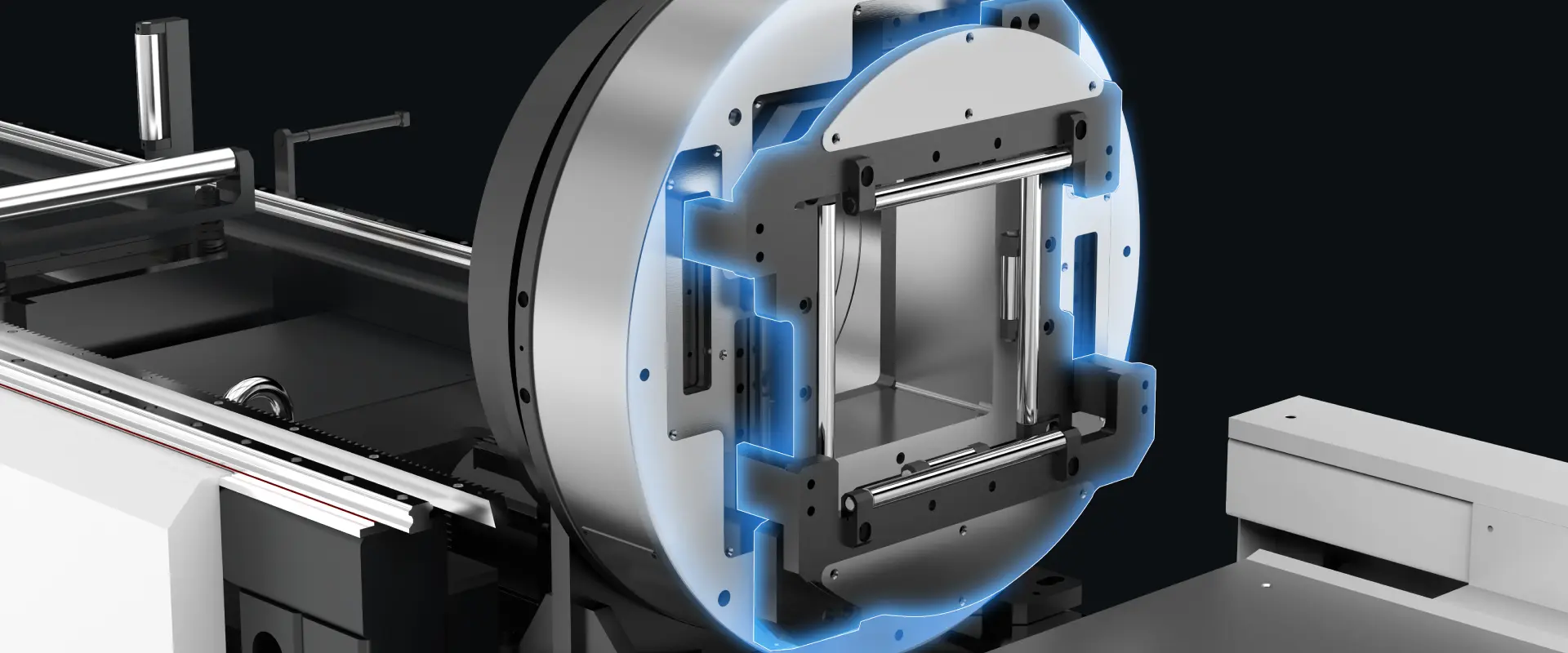

Chucks

Square hole design

breaks through the limitation of round holes and has a wider clamping range. When clamping square Tubes, rectangular Tubes, special-shaped Tubes and profiles, it can achieve processing for large Tubes, helping to save machine investment;

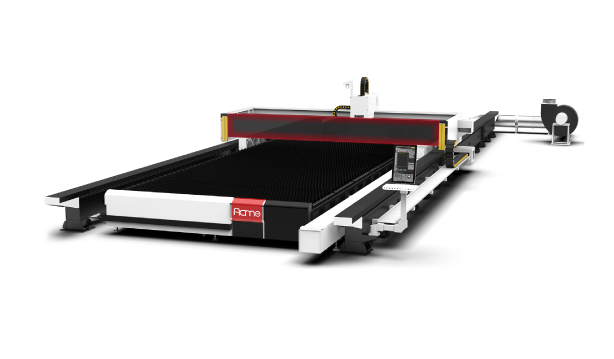

Light type design

adopts high-speed, lightweight structure design and is equipped with high-precision servo motors, with small rotational inertia, improving cutting speed and precision;

Full stroke design

No need to change the chuck claws improving productivity; the clamping force is twice as strong as that of ordinary chucks;

Innovative technology

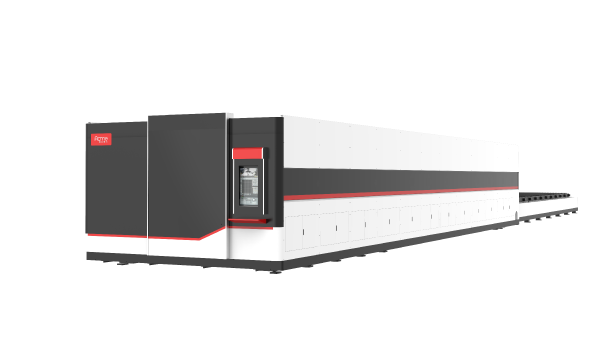

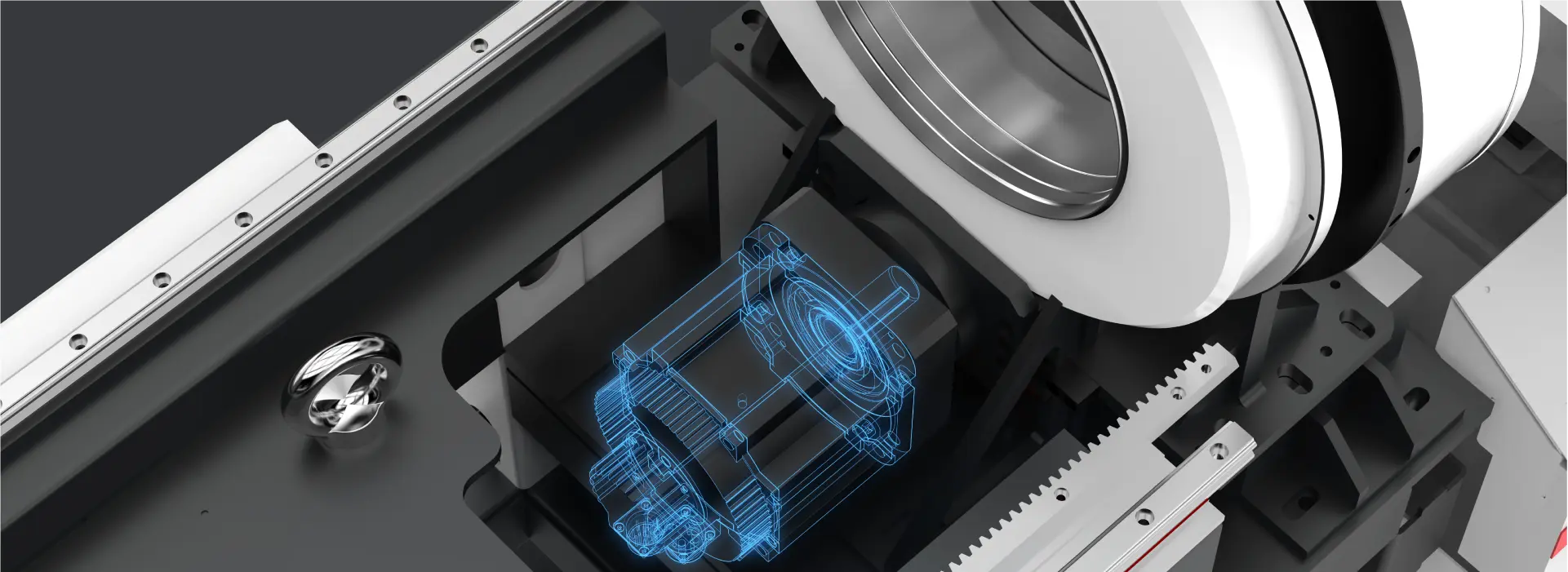

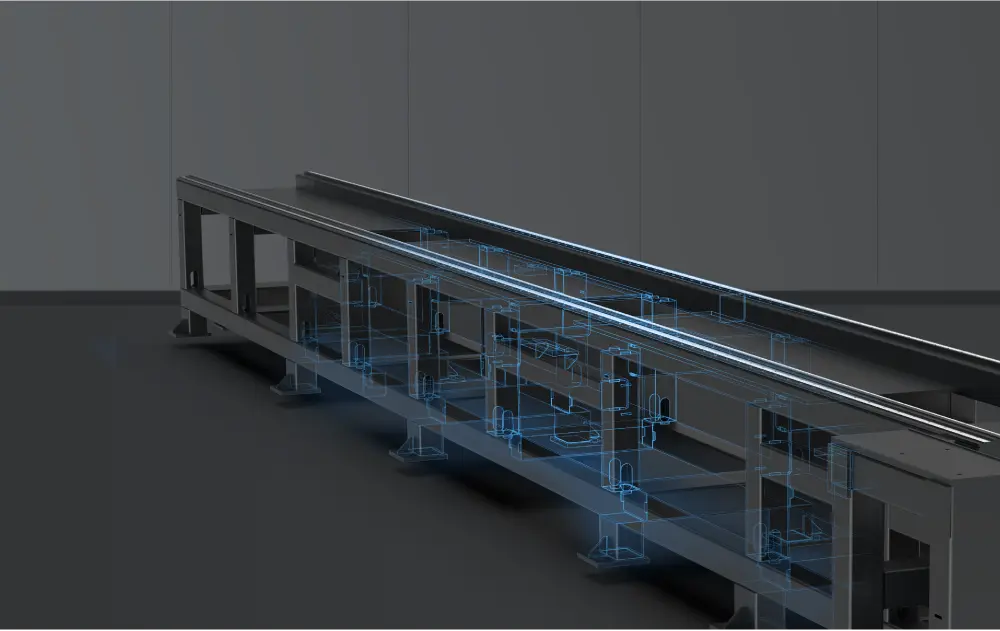

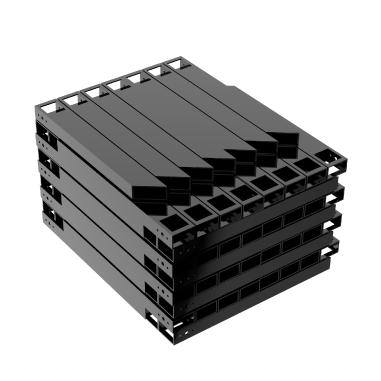

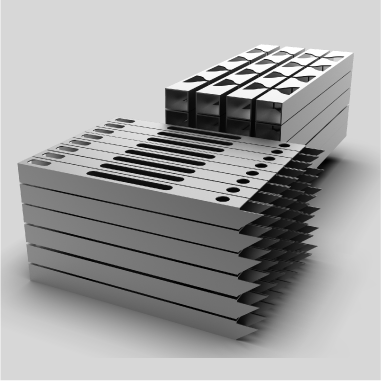

Mortise and tenon structure bed

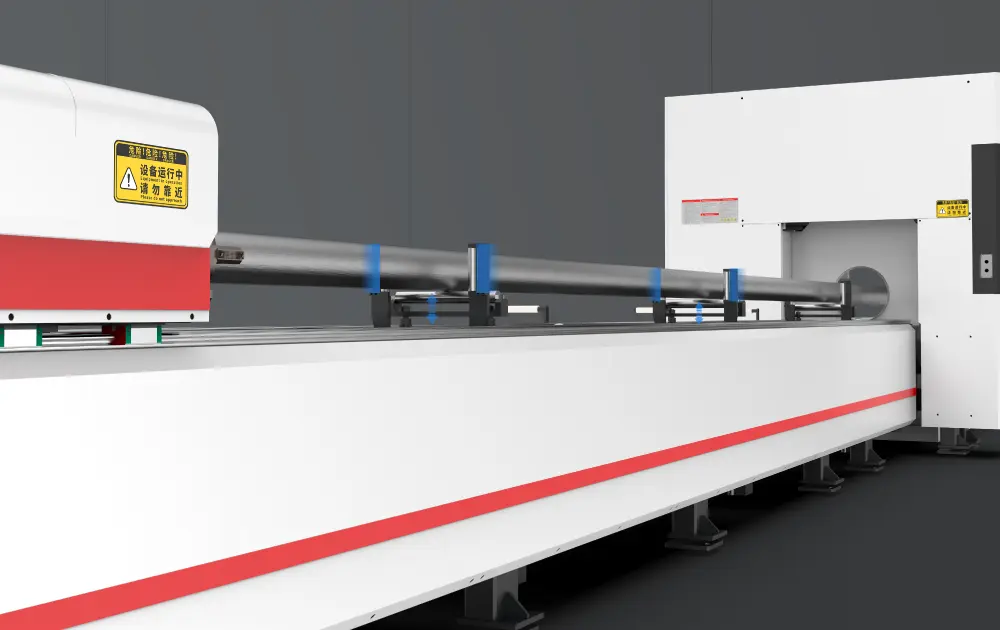

Segmented servo support

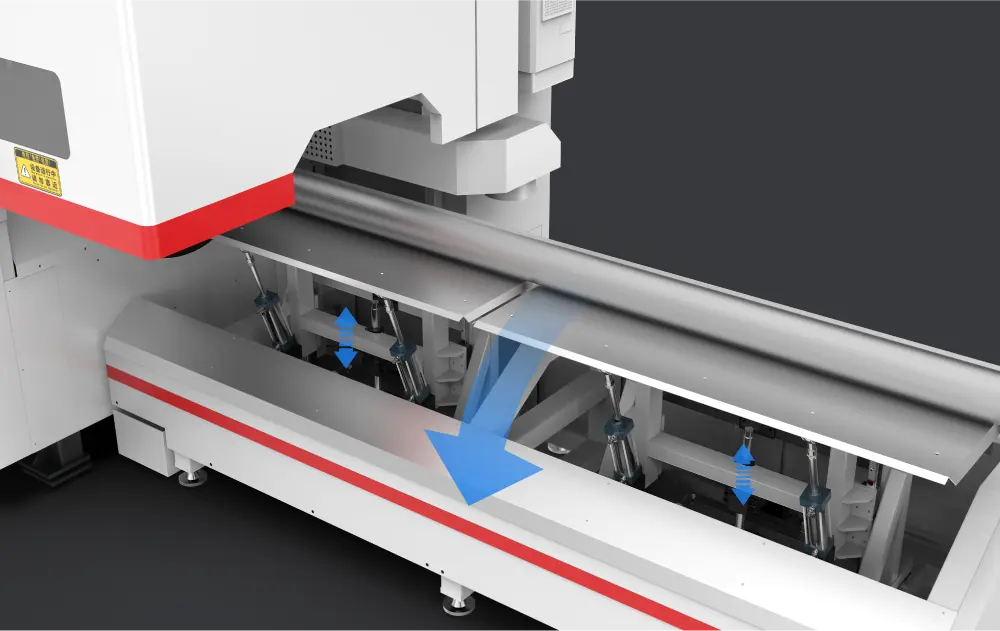

Automatic unloading device

Mortise and tenon structure bed

Each steel plate and each steel Tube of the bed is cut by laser, and the bed structure is professionally plug-in designed, with a position accuracy error of no more than 0.5mm, which effectively improves the service life and production efficiency of the equipment.

Segmented servo support

Cooperating with the system intelligently, it can self-center various Tubes and adjust the height in real time to achieve optimized control during the cutting process and ensure cutting accuracy. Reduce adjustment time and speed up the production process.

Automatic unloading device

Follow-up servo support for unloading, as the height of the Tube rotating, real-time adjustment, smooth blanking inertia, and ensure uniform blanking of the Tube. Protect the surface of the work-piece from damage and ensure the quality and accuracy of the work-piece.

User-friendly design

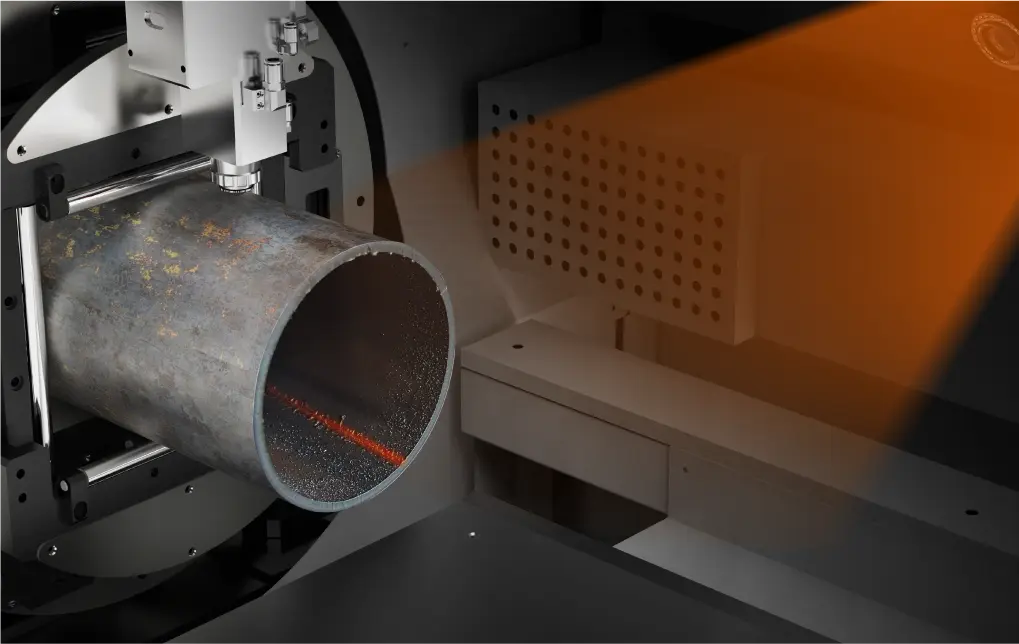

After accurately identifying the weld seam, the cutting path can be planned more reasonably, the quality of the cutting surface can be guaranteed, and the qualified rate of the product can be improved.

When the chuck is in high-speed working state, once an intruder is detected, an alarm will be immediately issued to prevent collision and ensure the safety of workers and machines.

The waste gas generated during the processing can be removed in time to ensure a clean and healthy working environment.

NEED Help?

Can't Decide Which Acme Laser Machine for your needs?

Contact Us

Keep reading the Technical Information

Product appearance, parameters, performance description, comparison data is for reference only, the final in kind shall prevail!

What we can do

Competitive Advantage

Being able to quickly manufacture precision parts and cut complex shapes with flexible and diverse design solutions, it can meet the processing needs of a wide range of metals.

Innovative design can save processing time and cost.

Sample display

Automobile manufacturing industry

External processing industry

Automobile manufacturing industry

Fitness equipment industry

Automobile manufacturing industry

Keep reading the Applications

industry cases

Machinery industry

It can cutting heavy and long workpieces can be whole perforated cut off

DISCOVER MORE

Elevators manufacturing

It can adapt to any metal pipe within 1.5 tonnes, all kinds of complex shapes and special materials processing needs.

DISCOVER MORE

Fitness equipment

Material utilisation can be increased by means of nesting software.

DISCOVER MORE

Steel market external processing

No need to dismantle and replace the jaws to improve production efficiency.

DISCOVER MORE

At present, Dong Fang Hao Yu has purchased two professional laser tube cutting machines LT-9017ES from ACME, they have been serving good operation for customers for two years. These two devices have brought great convenience to the company's production and can meet the various photovoltaic bracket columns cutting needs, which is basically consistent with ACME's promise at the time.”

Brought great convenience

READ THE FULL STORY

"The heavy duty side-mounted machine of ACME, both in terms of performance and processing quality, can stand the test of time!"

improving labor production efficiency

READ THE FULL STORY

"Since purchasing ACME laser machine, our elevator production efficiency has been greatly improved, and the product quality has also been significantly improved. The cutting effect is exquisite and the processing flexibility is high, which has truly solved our problems!"

High-quality processing

READ THE FULL STORY

"Since we purchased these three machines from ACME, we have received more and more orders. In general, the quality, delivery time and output have all improved, and we can meet all customer requirements perfectly. Customers are increasingly trusting us. In addition, ACME has changed our original production model. Currently, we can provide customers with one-stop services, from purchasing raw materials, cutting pipes, welding to galvanizing. With more and more orders, we plan to purchase another one"

Innovative production methods for customers

READ THE FULL STORY

Photovoltaic Bracket Industry

Heavy machinery industry

Elevator manufacturing industry

Steel market external processing,