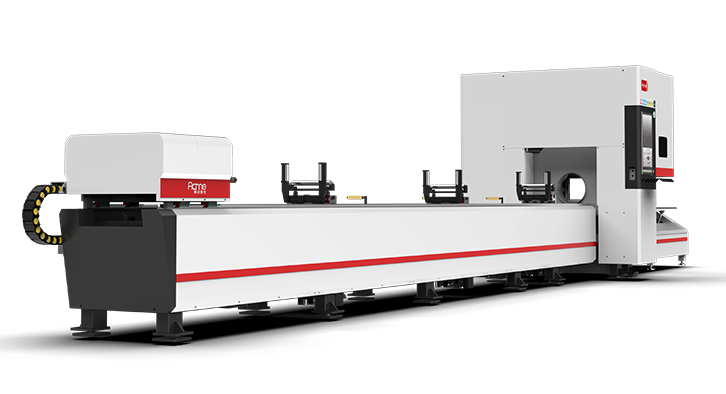

ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

Cutting precision can hardly meet the modern production demand

Lagging technology update

Low degree of automation

Unstable cutting quality

Slow processing speed

Material waste is serious

High metal cutting dust during processing

Generation of harmful gases during cutting

Noise pollution

Three chucks linkage to solve 90% of zero tailing problems

All three chucks can be moved, the middle chuck can be moved to the right side, allowing the last workpiece to be cut with high quality, achieving zero tail material cutting and reducing material waste.

Full-stroke pneumatic chucks

No need to dismantle and replace the jaws to improve production efficiency; large clamping force, twice as much as ordinary chucks; square hole design, pipe throughput is stronger.

Servo supports

Independently develop and manufacture servo support, which solves the problem of pipe shaking and deformation during the cutting process, and can be adapted to pipes of different diameters, shapes and lengths to improve the versatility of the equipment.

Square Hole Chucks

Have a wider clamping range. When clamping square tubes, rectangular tubes, shaped tubes and profiles, it can achieve a larger size range of processing, helping you to save equipment investment; each part of the tripod point self-developed chuck has an ID number, which is convenient for maintenance.

Flexible Unloading

The automatic unloading device can be adjusted in real time according to the height of the pipe rotation, smoothing out the inertia of the falling material and guaranteeing the even falling of the pipe. Support customising your pipe unloading size, such as: 3/6/9/12m etc.

High Degree Of Automation

Intelligent bus system, convenient operation and simplified action, reducing the operation difficulty and error rate, and improving safety;