ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

Industry

Time

Region

It is mainly caused by traditional processing methods. Longhua Technology's heat transfer equipment generally uses large steel frame bases, gas and liquid conduction pipelines, etc. The profiles are large in size, require grooves, and have high precision requirements. However, the sawing machines, flame cutting machines, drilling machines and other equipment that were originally relied on have complicated processes and many processes. At the same time, there are problems such as poor precision, easy deformation and low material utilization. Based on a deep understanding and precise control of the industry, ACME provides two solutions for the application requirements of heat transfer equipment for profiles, plates, and material thickness, as follows.

Production efficiency has increased dramatically

Production efficiency has increased by more than 60%. One machine can cover many processes, and there is no need for sawing, drilling or deburring. The processing time is greatly shortened, the number of parts is greatly reduced, and the errors and inconsistencies caused by manual operation are avoided! The work that used to take four or five people to complete can now be done by almost one person.

High bevel cutting accuracy

In the past, when we made bevels for pipes, there were always problems such as large gaps and missing arcs, which made it very difficult to splice and further processing. ACME bevel tube laser is different. As long as the drawings are imported into the system, it can cut the shape and size of the bevel completely according to the drawings. It has high precision, small welds, and good fit. It is convenient for subsequent welding and improves the welding quality.

Strong processing capacity

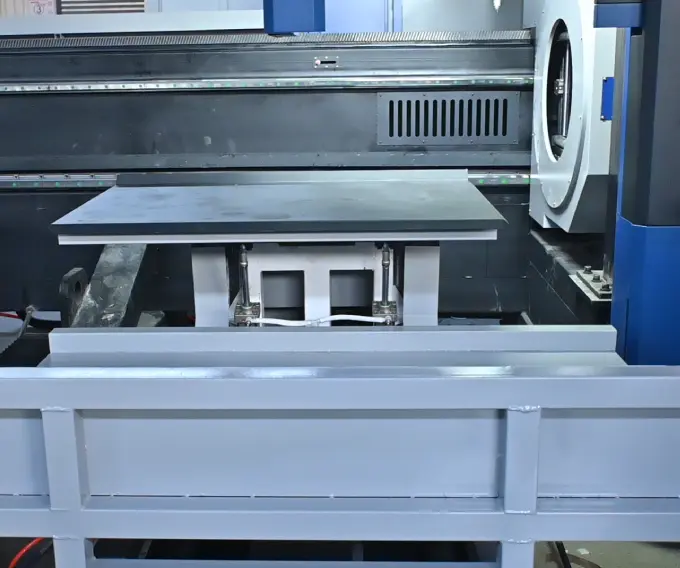

The tube laser base bearing capacity must be strong! The frame is mainly composed of H-steel, I-beam, channel steel and thick steel plate, and the cross-section length is about 1 meter. A professional profile cutting machine is required for processing. The ACME model is very good. It can cut profiles and plates. After using it, the cross section is very good, no need for secondary processing, and the speed is much faster, which reduces a lot of trouble!

Wide range of applications

Currently, we have purchased three machines from ACME. Now, no matter carbon steel pipes, alloy steel pipes, stainless steel pipes, bearing steel pipes, non-ferrous metal pipes, I-beams, H-beams, L-beams, U-beams, channels, angles, hot-rolled steel strips, cold-rolled steel strips, thin plates, medium plates, thick plates, and extra-thick plates, all can be cut perfectly, and complex processes can be easily completed. Whether it requires high-precision cutting or requires fast and large-scale cutting operations, it is very reliable, which brings a lot of convenience to our work.

info@acmelaser.com

+86 13863469522

We will contact you at the first time. If the enquiry is urgent, feel free to call! To get the final price, please fill in all detailed fields so that we can send you a detailed quotation according to your requirements and budget.

Director:

sally

Email:

info@acmelaser.com

WhatsApp:

+86 13863469522