ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

Industry

Time

Region

Due to the traditional plasma cutting and drilling processes, the ports are not aligned, the welding quality is not good, the workpiece-to-workpiece docking holes are not in the right position, and the screw holes have deviations, which seriously affect the quality and service life of the elevator. Moreover, the processing time is long, and it is difficult to meet the market's demand for diversified and personalized elevator products, resulting in high product development costs.

Efficient tube processing:

ACME's EA model can easily handle the various metal pipes processing, whether it is commonly used round pipes such as φ50×4, φ76×5, φ89×5, or square pipes such as 50×50×5, 60×60×4, etc., it can achieve accurate and efficient cutting. The maximum pipe diameter is φ 500mm, which meets our different pipe specifications.

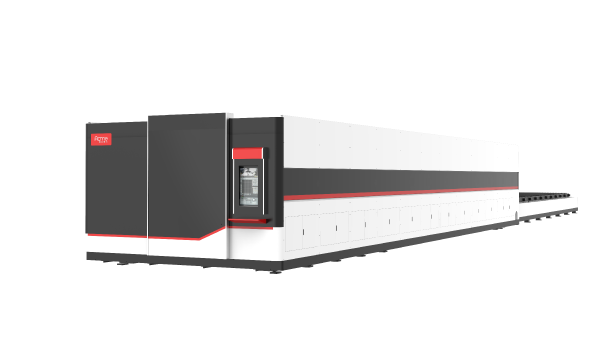

High-quality plate cutting:

It mainly cuts carbon steel plates within 16mm, especially steel structure connection plates, which provides strong support for the structural stability of the elevator. The cutting surface is smooth, flat and beautiful, avoiding deformation during the cutting process and improving the product grade.

Meet complex processes:

The machine has beveling function, and can accurately cut complex shapes and interfaces, especially medium-sized profiles such as H-shaped steel and channel steel.

Significantly improve efficiency:

Orders that originally took a long time to complete can now be delivered quickly, effectively shortening the processing cycle. At the same time, product quality is significantly improved and processing errors like rework and scrap are reduced.

info@acmelaser.com

+86 13863469522

We will contact you at the first time. If the enquiry is urgent, feel free to call! To get the final price, please fill in all detailed fields so that we can send you a detailed quotation according to your requirements and budget.

Director:

sally

Email:

info@acmelaser.com

WhatsApp:

+86 13863469522