ACME core products, laser tube cutting machines and laser sheet cutting machines, are sold well in 60 countries and regions around the world. The following is the distribution of our sales regions. Welcome to get in touch with your nearest Regional Manager.

Industry

Time

Region

In order to actively respond to national policies and accelerate the development of new energy industries, the Installation Branch of Power Construction Hydropower Bureau No. 11 plans to significantly increase production capacity. However, the original equipment has problems such as low efficiency, insufficient precision, and material waste when processing heavy and long work-pieces, which makes it difficult to meet the high-quality and diversified processing needs of new energy projects for tower accessories, platform supports, guardrails, photovoltaic brackets, etc.

Effectively improve production capacity

After the introduction of ACME machine, the production capacity is effectively improved:

tower manufacturing: production capacity reaches 3500-4500 tons/month, and production capacity can reach more than 120-150 sets one year;

photovoltaic steel bracket manufacturing: production capacity is 2000 tons/month, and the production capacity can reach the required amount of 400MW photovoltaic brackets one year, which effectively improves the company's competitiveness in the field of new energy.

Zero-tailing cutting

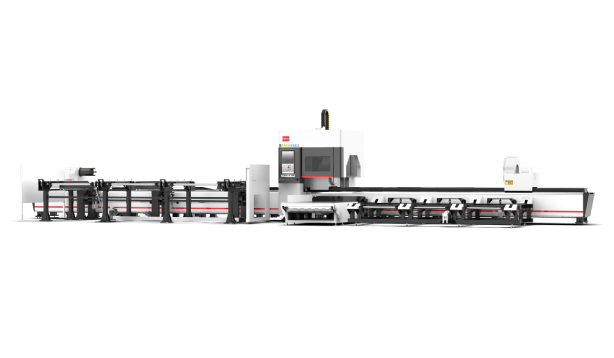

The three-chuck machine can achieve zero tailing cutting, saving a lot of materials and costs. Through nesting software, material utilization is also increased. It can cut any shaped tubes, with high flexibility, not affected by different work-pieces in the project.

Wide range of applications

ACME’s machine can process all the tubes, such as angle iron, channel steel, round tube, square tube, I-beam, which are need in the processing of wind tower internals, platform supports and guardrails, wind power transportation tooling, wind power transmission tower booster station

Labor-saving

The cutting effect is good, smooth and neat, without burrs, eliminating the subsequent grinding and other processes, saving a lot of labor time and costs, reducing the errors and unstable quality problems that may be caused by manual operation. At the same time, the machine has low requirements for operator skills, and new operator can quickly get started.

info@acmelaser.com

+86 13863469522

We will contact you at the first time. If the enquiry is urgent, feel free to call! To get the final price, please fill in all detailed fields so that we can send you a detailed quotation according to your requirements and budget.

Director:

sally

Email:

info@acmelaser.com

WhatsApp:

+86 13863469522